TPR vs. TPE: Which Material Is Right for Your Project?

TPR and TPE have flexibility, durability and plasticity. TPR and TPE look similar, but the difference between them is crucial, they are different in terms of processing technology, cost, strength and application.

Choosing the wrong materials can lead to product failure and costly redesign, understanding them can help you avoid costly mistakes. At the same time, it is always a wise choice to communicate with manufacturing processing experts – such as VMT, who can provide you with professional advice on material selection.

What is TPR?

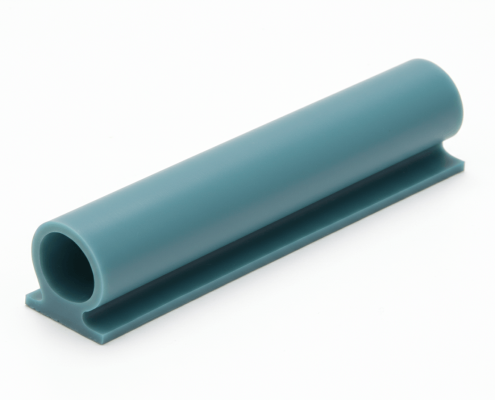

“TPR” does not refer to a class of materials, but rather to a specific material with a specific chemical composition, thermoplastic rubber, which is a mixture of rubber and plastic polymers. It combines the soft touch of rubber with the processing properties of thermoplastics. TPR behaves like vulcanized rubber at room temperature, but melts and flows like plastic at elevated temperatures, making it ideal for injection molding and extrusion processes.

TPR rubber can be recycled and remolded, which is cost-effective and has a wide range of uses. TPR is often used to make grips, toys, seals, and shoe soles. Its flexibility and shock-absorbing properties are ideal for consumer products, but its chemical resistance is not as good as TPE. If you use TPR plastic, it can be easily processed and shaped using CNC machining technology for low-volume prototyping.

What is TPE?

TPE, or thermoplastic elastomer, is a class of materials that have both thermoplastic and elastomer properties. It is soft, stretchable, and easily molded using thermoplastic elastomer molding processes. Thermoplastic elastomers are processed similarly to plastics, and are typically synthesized using graft polymerization. Common types include TPE rubber, TPV, TPO, and TPEE.

Its applications include automotive plastic TPE, TPE gloves, consumer TPE materials, and medical-grade components. It is also increasingly popular in CNC TPE prototyping for customized, high-precision products.

What are the differences between TPR and TPE?

TPR and TPE are both elastic materials with rubber properties, but there are some differences. TPR is a type of TPE, mainly a mixture of plastic and rubber, and has good elasticity. TPE is a broader material category that includes a variety of materials that have rubber properties but can be processed like plastics, with greater design flexibility and better temperature resistance. Here are their specific differences:

1. TPR vs. TPE: Physical Properties

TPR has a Shore hardness range between 20A to 90A, making it a softer and cheaper choice for tactile products. Its melting point ranges between 200°C to 280°C, suitable for standard plastic processing.

TPE offers a more elastic feel, and supports a wider hardness scale from 10A to 60D. It also withstands broader temperature ranges and performs better in high-heat or -cold applications. Its tpe material properties like tensile strength, elongation, and tear resistance are superior in demanding environments. In CNC prototyping, TPR is easier to manipulate, while TPE polymer is better for creating fine-detail, high-performance components.

2. TPR vs. TPE: Durability and Strength Comparison

TPE rubber outperforms TPR in rugged applications due to its superior resistance to chemicals, UV exposure, and fatigue. It remains durable under repeated stress and harsh environmental conditions.

On the other hand, while TPR is strong, it is more vulnerable to degradation from UV light and aggressive chemicals, making it more prone to cracking and discoloration over time.

| Property | TPR | TPE |

|---|---|---|

| UV Resistance | Low | High |

| Chemical Resistance | Low-Moderate | High |

| Abrasion Resistance | Moderate | High |

| Fatigue Resistance | Good | Excellent |

| Elongation | Up to 400% | Up to 700% |

3. TPR vs. TPE: Cost Analysis

Cost is a decisive factor in large-scale thermoplastic elastomer molding. TPR is generally more economical in terms of raw material cost and production cycle.

TPE, especially medical or antistatic TPE, is more expensive but still provides reliable performance in harsh environments such as automotive or aerospace. In critical applications, lower failure rates and longer service life can often justify their cost.

Frequently Asked Questions About TPR and TPE

What are the Advantages of TPR Materials?

TPR materials offer excellent flexibility, softness, and ease of processing, making them ideal for consumer products like shoe soles, grips, and toys. They are cost-effective, recyclable, and compatible with various molding techniques. Additionally, TPR has good weather resistance in moderate conditions and provides a rubber-like feel with high elasticity.

What are the Advantages of TPE Materials?

TPE materials are highly versatile, with superior elasticity, tear resistance, and durability. They resist chemicals, UV rays, and extreme temperatures, making them suitable for automotive, medical, and industrial applications. TPE is also recyclable, skin-friendly, and ideal for intricate designs or prototyping with CNC or 3D printing.

Is TPR plastic Safe to Use?

Yes, TPR plastic is generally safe for use in consumer products, including toys and utensils, as it is non-toxic and hypoallergenic. However, safety depends on specific formulations, so always verify that the material meets industry standards for your application.

What is a TPR Valve?

A TPR valve is a safety device used in hot water systems to release water and reduce pressure if the system exceeds safe temperature or pressure limits. It prevents damage or explosions by providing a controlled release.

Is TPE Toxic?

TPE is generally considered non-toxic and safe for various applications, including medical and consumer products. Its skin-friendly properties make it suitable for items like wearable devices and baby products. However, the safety depends on the specific additives and formulations used. Always ensure compliance with relevant safety standards.