The pursuit of high-quality, precision-engineered components is a constant in modern manufacturing. As industries demand increasingly complex parts with tight tolerances, the choice of your manufacturing partner becomes paramount. For many, China represents a powerhouse of manufacturing capabilities, particularly in CNC turning.

Yet, identifying a truly exceptional CNC turning parts manufacturer amidst a vast market can be a significant challenge. You face the problem of sifting through countless options, risking potential delays, quality issues, and communication breakdowns if you choose poorly. This guide is designed to empower you with the knowledge and criteria to confidently select a top-tier partner, one that not only meets but exceeds your project’s demands.

What is CNC Turning?

CNC turning is a subtractive manufacturing process that uses computer-controlled lathes to remove material from a rotating workpiece. It is crucial for producing cylindrical or conical parts with high precision and excellent surface finishes. This process is fundamental across diverse sectors.

From intricate medical devices to robust aerospace components, CNC turning delivers the accuracy required for critical applications. Its versatility in handling various materials, including metals and plastics, makes it indispensable for modern product development. You rely on this technology for components that demand tight dimensional control.

Why Choose a chinese CNC Turning Manufacturer?

China’s long-standing dominance in the manufacturing sector presents a highly attractive market for CNC turning parts. Its advanced infrastructure, skilled workforce, and competitive costs combine to create a highly attractive environment for global businesses.

Chinese manufacturers frequently invest in cutting-edge technology, ensuring they have access to the latest CNC turning capabilities. This scale and innovation translate directly into efficient, high-quality production for your projects.

Leading CNC Turning Parts Manufacturers in China

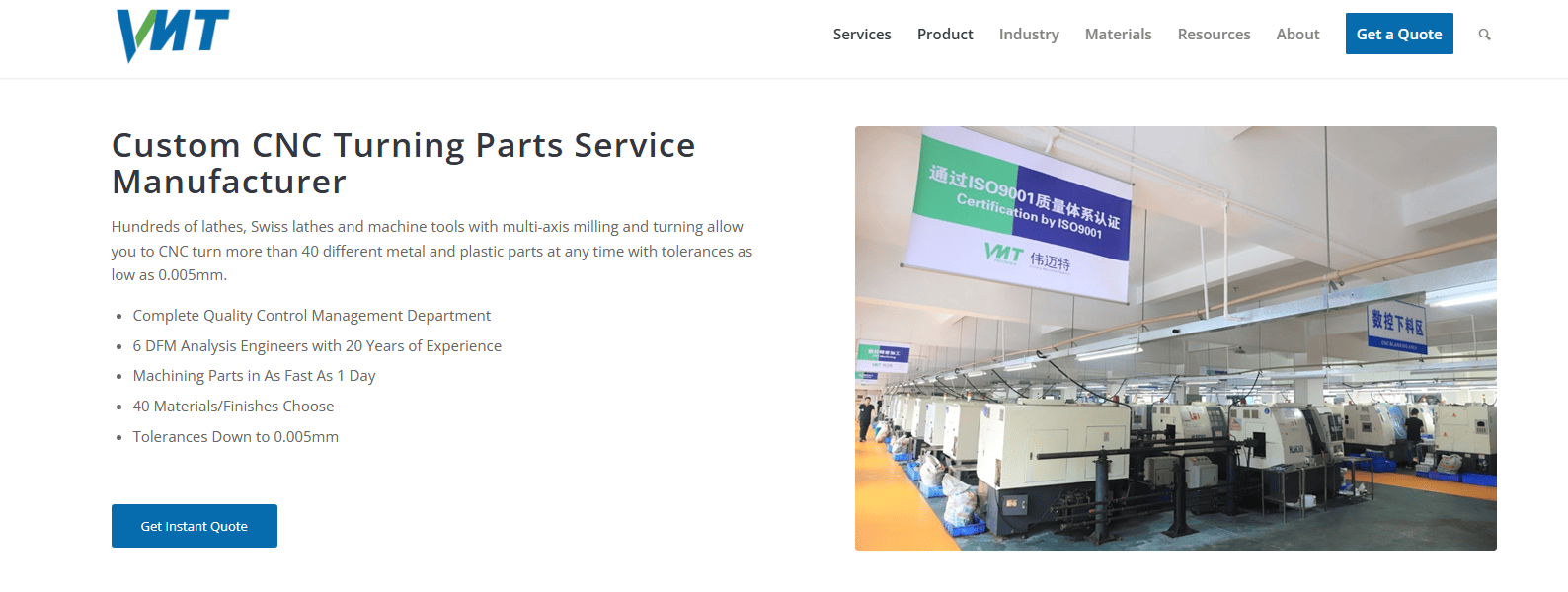

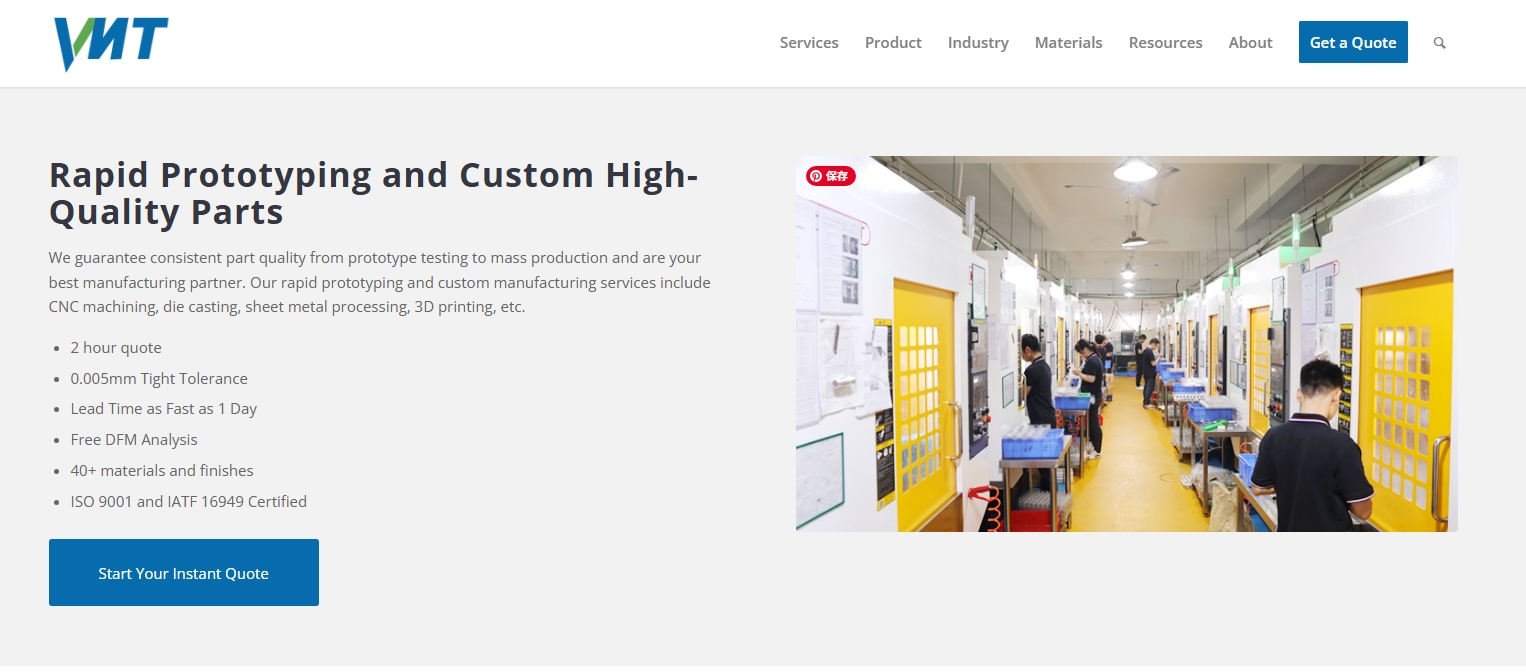

1. VMT

VMT is a top CNC turning manufacturer, provides rapid turnaround with quotes in two hours, DFM feedback within 24 hours, and delivery as fast as 3 day. The company works with tolerances down to ±0.005 mm and serves industries including medical, automotive, agriculture, electronics, lighting, and oil & gas. Products are exported to 62 countries, and the firm is recognized for combining speed, flexibility, and high-quality results.

The company holds ISO 9001 and IATF 16949 certifications and over 11 patents, with manufacturing areas covering 12,000 m² and 100+ machines. It offers forging, casting, extrusion, CNC turning and milling, and surface finishing, ensuring complete in-house solutions.ensuring complete in-house solutions for sectors such as medical devices and high-performance bicycle components.

2. Machining Custom

Machining Custom specializes in custom CNC machining services, offering precision manufacturing solutions for a diverse range of industries. The company operates a comprehensive facility equipped with advanced machinery, including high-speed CNC lathes, automatic lathes, CNC milling machines, drilling and tapping equipment, grinding machines, welding machines, and tube bending machines.

3. Gensun Precision Machining

Gensun Precision Machining, established in 2006 in Dongguan, is a highly certified CNC manufacturer with ISO 9001:2015, ISO 14001:2015, and ISO 13485:2016 accreditations. The company works with a wide range of materials, including aluminum, steel, stainless steel, brass, copper, plastics such as POM, PTFE, PC, and PEEK. Gensun is known for its fast delivery times, rigorous quality control procedures, and ability to produce precision parts for both small and medium batch production.

4. HLC Metal Parts

HLC Metal Parts Ltd, founded around 2008 in Dongguan, specializes in precision CNC turned and milled components for medical and automotive applications. The company holds ISO 13485 certification for medical devices and IATF 16949 for automotive components, ensuring compliance with strict quality standards. Its 3,500+ sqm facility is equipped with 80+ CNC lathes, milling machines, 5-axis centers, and laser cutting and grinding machines.

5. Frima

Frima focuses on rapid prototyping and small-batch CNC turning and milling. The company holds ISO 9000 and TS16949 certifications and is highly responsive, making it ideal for sample orders and fast design iterations. Frima’s 2,500 sqm workshop houses over 50 CNC machines and 3D scanning and inspection tools to support precise prototyping.

6. MXM

MXM, established in 2006 in Ningbo, provides CNC-turned parts alongside metal stamping services. The company is ISO 9001:2015 certified and serves industries such as automotive, electronics, and industrial machinery. Its 3,000 sqm facility includes over 60 CNC lathes, 40 stamping presses, and a fully equipped inspection lab with CMM and projection systems. MXM works with stainless steel, brass, aluminum, copper, alloys, and plastics.

7. CNC Precision Machining

CNC Precision Machining in Shenzhen operates a large-scale facility with more than 100 skilled technicians and over 4,000 sqm of workshop space. The company provides high-precision CNC turned and milled components for volume production. Its equipment includes CNC lathes, 3–5 axis milling machines, EDM, and grinding machines, and it works with aluminum, steel, stainless steel, titanium, plastics, and specialty alloys.

8. ZX CNC Machining

ZX CNC Machining, founded around 2012 in Dongguan, leverages Industry 4.0 technologies to provide automated and efficient CNC production. Its 3,500 sqm workshop is equipped with over 80 CNC machines, 5-axis centers, automated lathes, robotic material handling, and in-process inspection systems. The company is recognized for smart manufacturing, automated QC, fast prototyping, and excellent traceability of parts.

9. LJZ

LJZ has over 20 years of CNC machining experience and specializes in high-precision and medical-grade components. It holds ISO 9001, ISO 13485, and SGS certifications. LJZ’s 2,500 sqm facility includes over 60 CNC lathes and mills, EDM, grinding machines, and advanced inspection systems like CMM and optical measurement tools. It works with stainless steel, titanium, aluminum, and high-performance plastics, producing ultra-precision parts for medical devices, electronics, and other high-tech applications.

10. KinTec Machining

KinTec Machining, founded in 2010 in Dongguan, focuses on rapid prototyping and low-volume CNC production. Its 2,000 sqm workshop houses more than 50 CNC machines, including 3–5 axis mills, lathes, laser engraving, and inspection tools. KinTec works with aluminum, stainless steel, brass, copper, and engineering plastics.

Summarizing the Top 10 CNC Turning Parts Manufacturers in China

| Company | Facility & Equipment | Materials | Key Strengths / Industries |

|---|---|---|---|

| VMT | 12,000 m², 100+ machines, CNC turning/milling, forging, casting, extrusion, surface finishing | Steel, aluminum, stainless steel, copper, bronze, brass, alloys | Rapid quotes (2h), DFM feedback in 24h, tolerances ±0.005 mm; medical, automotive, agriculture, electronics, lighting, oil & gas; exports to 62 countries |

| Machining Custom | Advanced CNC lathes, automatic lathes, milling, drilling/tapping, grinding, welding, tube bending | Steel, aluminum, stainless steel, copper, bronze, brass, alloys | Custom precision CNC solutions for diverse industries; full-service capabilities |

| Gensun Precision Machining | Not specified | Aluminum, steel, stainless steel, brass, copper, POM, PTFE, PC, PEEK | Fast delivery, strict QC, small/medium batch production; medical, automotive, electronics, industrial machinery |

| HLC Metal Parts | 3,500+ sqm, 80+ CNC lathes/mills, 5-axis centers, laser cutting, grinding | Steel, aluminum, stainless steel, titanium, plastics | Precision CNC turned/milled parts for medical and automotive; compliance with strict quality standards |

| Frima | 2,500 sqm, 50+ CNC machines, 3D scanning and inspection tools | Aluminum, steel, stainless steel, plastics (POM, ABS, PC, PTFE) | Rapid prototyping and small-batch runs; fast design iterations; precise prototypes |

| MXM | 3,000 sqm, 60+ CNC lathes, 40 stamping presses, CMM and projection systems | Stainless steel, brass, aluminum, copper, alloys, plastics | CNC turning + stamping; automotive, electronics, industrial machinery; medium/high-precision components |

| CNC Precision Machining | 4,000 sqm, 100+ technicians, CNC lathes, 3–5 axis milling, EDM, grinding | Aluminum, steel, stainless steel, titanium, plastics, specialty alloys | High-volume production; high-precision CNC turned/milled components; large-scale facility |

| ZX CNC Machining | 3,500 sqm, 80+ CNC machines, 5-axis centers, automated lathes, robotic handling, in-process inspection | Aluminum, stainless steel, brass, titanium, PEEK, plastics | Industry 4.0 automated production; fast prototyping; excellent traceability; smart manufacturing |

| LJZ | 2,500 sqm, 60+ CNC lathes/mills, EDM, grinding, CMM, optical inspection | Stainless steel, titanium, aluminum, high-performance plastics | Ultra-precision CNC components; medical devices, electronics, high-tech applications; decades of experience |

| KinTec Machining | 2,000 sqm, 50+ CNC machines, 3–5 axis mills, lathes, laser engraving, inspection tools | Aluminum, stainless steel, brass, copper, engineering plastics | Rapid prototyping, low-volume production; flexible customization; small-batch CNC parts |

In Conclusion

Identifying a top CNC turning parts manufacturer in China requires a discerning eye for specific, quantifiable attributes. From extensive production capacity and cutting-edge machinery to an unwavering commitment to precision, multi-stage quality control, and agile lead times. As you navigate your options for CNC turning parts in China, consider VMT in Shenzhen as a partner that not only meets but often exceeds these stringent criteria. Our dedication to innovation, precision, and client satisfaction positions us as a premier choice for your critical manufacturing needs.

Contact us today to discuss your CNC turning requirements and explore how VMT can bring your designs to life with unparalleled quality and efficiency.

Frequently Asked Questions

What Types of Materials Can be CNC Turned by a Top Manufacturer?

A top CNC turning manufacturer can process a wide range of materials, including various grades of aluminum (e.g., 6061, 7075), stainless steel, brass, copper, titanium, and engineering plastics. This versatility ensures they can meet the specific property requirements of your application.

How Can I Ensure Quality When Working With a CNC Turning PIarts Manufacturer in China?

To ensure quality, look for manufacturers with a robust, multi-stage quality control system (like VMT’s 12-stage process). This includes DFM reviews, incoming material inspection (IQC), in-process quality checks (IPQC), final inspection (FQC/OQC), and a commitment to continuous improvement (QE). Certifications and transparent communication are also key.

Does VMT Offer Design Support for CNC Turning Projects?

Yes, VMT provides complimentary Design for Manufacturability expert consultation during your design phase. Our engineers can review your blueprints, offer suggestions for optimizing part design for cost-effectiveness and manufacturability, and help prevent potential issues before production begins.