VMT’s blogs aim to share our hard earned knowledge on manufacturing and product development. We hope these articles help you to optimize your product design and better understand the world of rapid prototyping, rapid tooling, 3D printing and low-volume manufacturing.

Surface Treatment Methods In CNC Machining

In the vast world of manufacturing, surface treatment is crucial after CNC machining. It not only beautifies the appearance of the product, enhances wear resistance and corrosion resistance, improves accuracy and extends service life, but also meets the needs of different application scenarios through customized processing, significantly improving product-added value and market competitiveness. This article will give you an in-depth understanding of surface finishing methods in CNC machining, and explore the principles, advantages, selection basis, etc. of various machining technologies.

What Is Surface Finishing?

Surface finishing, also known as surface technology, is to change the surface state, chemical composition, organizational structure and stress state of the workpiece through mechanical, physical or chemical methods, or to apply various covering layers, so that the surface of the workpiece has some special characteristics different from its matrix. Performance, an application technology that meets specific usage requirements.

Some common surface finishing techniques include:

1. CNC Painting:

Computer Numerical Control (CNC) painting is a precise and automated method of applying coatings, paints, or other finishes to the surface of a workpiece. It ensures a consistent and high-quality finish.

2. Machining and Finishing:

Processes like grinding, polishing, or honing are used to improve the surface texture, dimensional accuracy, and reduce roughness through mechanical modifications.

3. EDM Surface Finish:

Electrical Discharge Machining (EDM) is a non-traditional machining process that can create intricate surface patterns and textures, often used for decorative or functional purposes.

The choice of surface finishing technique depends on the material, the intended application, and the specific performance requirements. By carefully selecting and applying the appropriate surface finishing methods, manufacturers can ensure the workpiece meets the necessary standards for appearance, wear resistance, corrosion protection, and other critical characteristics.

Why Is Surface Finishing Important?

CNC machining lays a solid foundation for the product and provides a solid inner structure. Surface treatment is a detailed optimization and enhancement of this solid foundation. It not only involves fine cleaning, deburring, grease removal and other pre-treatments on the surface of the workpiece, but also improves the appearance of the product through scientific physical or chemical treatment methods, such as uniform gloss and natural color presentation, and is also effective Improved product durability and corrosion resistance.

Our Surface Finishing Services

From precision machining to comprehensive surface treatment services, we offer more than 40 surface finishing options designed to meet your diverse needs for corrosion resistance, wear resistance, aesthetics and extended service life. In order to ensure the excellent quality of each CNC machined part, we strictly implement 12 quality inspection processes to ensure that the yield rate of finished products is as high as 98%, so that you can trust every detail of the product.

Commonly Used Machining Methods After CNC Machining

Anodizing

Principle: The metal is placed in the electrolyte and used as an anode, and an oxide film is formed on the metal surface through electrolysis.

Application: Commonly used for surface treatment of aluminum and its alloys to improve corrosion resistance, wear resistance and hardness, while giving it a specific color and luster.

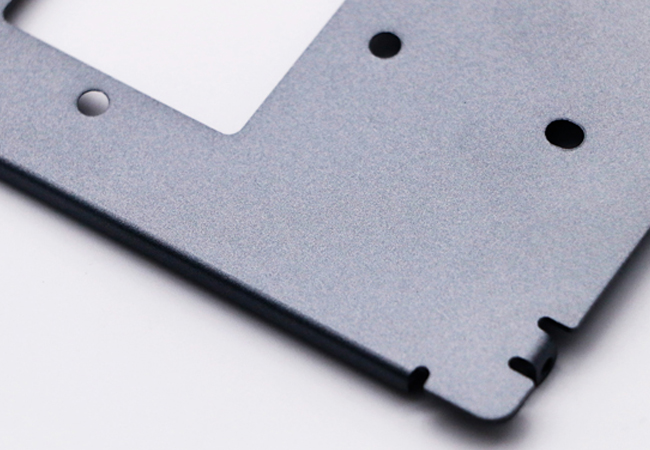

Sandblasting

Principle: Use the impact of high-speed sand flow to clean and roughen the surface of the substrate.

Application: It is often used to clean dirt, oxide scale, etc. on the surface of workpieces, while improving the surface roughness and adhesion to prepare for subsequent machining such as spraying, electroplating, etc.

Polishing

Principle: Use mechanical, chemical or electrochemical effects to reduce the surface roughness of the workpiece to obtain a bright and smooth surface.

Application: Commonly used for surface finishing of metals, plastics and other materials to improve appearance quality and corrosion resistance.

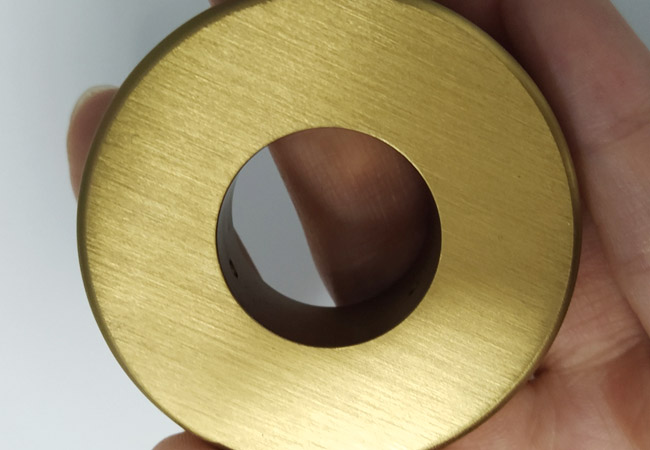

Brushed

Principle: Lines are formed on the surface of the workpiece through grinding to achieve a decorative effect.

Application: Commonly used for surface finishingt of metal materials, such as aluminum alloy doors and windows, stainless steel kitchenware, etc., to enhance the aesthetics and texture.

Plating

Principle: Use the principle of electrolysis to plate a thin layer of other metals or alloys on certain metal surfaces.

Application: Widely used to improve the corrosion resistance, wear resistance, conductivity and aesthetics of materials, such as chrome plating, nickel plating, gold plating, etc.

Electrophoresis

Principle: Under the action of an electric field, paint particles are deposited on the workpiece to form a film.

Application: Suitable for uniform coating of complex-shaped workpieces with good adhesion and corrosion resistance.

Powder Coating

Principle: Under the action of the electric field, the paint particles are electrostatically attracted and deposited on the surface of the workpiece, gradually forming a uniform coating film.

Application: Powder spraying is suitable for uniform coating of complex-shaped workpieces, and the coating film formed has good adhesion and excellent corrosion resistance.

Water Transfer Printing

Principle: Water transfer printing uses water as a medium to transfer the pattern to the surface of the substrate through the pattern on a special carrier (such as a film) under the action of an activator.

Application: This technology is widely used in many fields, especially in the automobile and motorcycle industries. It provides a variety of personalized decoration solutions for parts such as wheels and fuel tank caps; at the same time, in home decoration, electronic products and cosmetic packaging, water transfer printing technology also plays an important role.

Commonly Used for Plastics and 3D Printed Parts:

Surface finishing is a critical aspect of manufacturing and product design, as it can significantly impact the appearance, functionality, and performance of the final product. This is particularly important for plastic components and 3D printed parts, where the surface finish can make a significant difference in the overall aesthetic and practical applications.

The following table outlines the various types of surface finishing techniques commonly used for plastics and 3D printed parts:

Plastic Surface Finish Types:

| Finish Type | Description |

|---|---|

| Glossy | Provides a smooth, mirror-like, highly reflective surface. Achieved through polishing, buffing, or applying high-gloss coatings. Commonly used for decorative and aesthetic applications. |

| Matte/Satin | Creates a soft, non-reflective, low-sheen surface. Obtained by controlled texturing, bead-blasting, or applying matte coatings. Provides a subtle, uniform appearance. |

| Textured | Adds a deliberate surface pattern or texture. Can be achieved through embossing, molding, or applying specialty coatings. Provides a unique visual and tactile experience. |

| Metallic | Imitates the appearance of metal, such as gold, silver, or bronze. Accomplished by applying metallic paints, foils, or metallized coatings. Enhances the perceived value and luxury of the product. |

| Printed Graphics/Patterns | Allows for the application of intricate designs, logos, or imagery on the plastic surface. Achieved through techniques like pad printing, screen printing, or digital printing. Offers customization and branding opportunities. |

3D Printing Surface Finish:

In addition to providing CNC machining services, we also provide 3D printing services for our customers. The following are the various types of 3D printing surface treatments we can provide.

| Finish Type | Description |

|---|---|

| As-Printed | The natural surface finish directly from the 3D printing process. May have visible layer lines, surface roughness, or texture. Can be a cost-effective option for functional or prototype parts. |

| Sanding and Polishing | Post-processing techniques to smooth the surface and reduce roughness. Involves manual sanding, buffing, or polishing the printed part. Provides a more refined, uniform appearance. |

| Coating and Finishing | Application of paints, lacquers, or other coatings to the 3D printed part. Can enhance the surface smoothness, gloss, or specific visual/tactile qualities. Offers a wide range of customization possibilities. |

| Chemical Treatments | Using chemical agents to modify the surface, such as vapor smoothing or acetone smoothing. Helps reduce surface roughness and improve the overall finish. Requires careful handling and safety considerations. |

What are the Advantages and Disadvantages of Surface Finishing?

Advantage:

1. Improved Material Performance:

Surface finishing techniques can significantly enhance the corrosion resistance, wear resistance, hardness, electrical and thermal conductivity of materials, extending the service life and reliability of products.

2. Enhanced Appearance Quality:

Surface treatment can improve the aesthetic qualities of materials, such as gloss, color, and texture, making products more visually appealing and attractive.

3. Increased Adhesion:

Processes like sandblasting or chemical treatment can increase surface roughness, improving the adhesion of coatings or platings, leading to stronger and more durable finishes.

4. Reduced Maintenance Costs:

Improved corrosion and wear resistance through surface finishing can lower product maintenance costs and reduce the frequency of replacements or repairs.

Disadvantages:

1. Cost Increase:

Surface finishing often requires additional specialized equipment, materials, and skilled technicians, which can increase the overall manufacturing costs.

2. Environmental Impact:

Some surface finishing methods, such as electroplating or spraying, may produce harmful substances and waste, potentially causing environmental pollution. Appropriate environmental protection measures need to be implemented.

What are the Advantages and Disadvantages of Aluminum Surface Finishes?

Advantages:

- Aluminum is a lightweight, corrosion-resistant material that can benefit greatly from surface finishing to enhance its properties.

- Anodizing is a common surface finishing technique for aluminum, which can improve wear resistance, corrosion protection, and decorative appearance.

- Powder coating and other painting techniques can also be used to customize the color and finish of aluminum surfaces.

Disadvantages:

- The anodizing process can be relatively complex and may require specialized equipment and expertise.

- The environmental impact of certain aluminum surface finishing methods, such as the use of chemical baths, needs to be carefully managed.

Conclusion:

Surface finishing is an important step after CNC machining. It improves the surface properties of materials through physical or chemical methods to meet the needs of different industries for product performance, appearance and durability. This technology is widely used in automobiles, optics, automation, medical and other fields, providing reliable and effective solutions for the manufacturing industry.

FAQs About Surface Finishing

What Is The Difference Between Surface Finishing And Surface Coating?

Surface finishing and surface coatings are both used in manufacturing to improve the surface properties of materials, but there are differences. Surface finishing is a broad process concept, including mechanical, chemical, electrochemical and other methods, in order to give the material surface-specific properties or functions, such as corrosion resistance, wear resistance or decoration. Surface coating is a specific form of surface treatment, which specifically refers to the formation of a covering layer with specific functions on the surface of the material. This covering layer can be made of metal, ceramics or polymers.

What are the Metal Surface Finishing?

Metal surface finishing includes mechanical finishing (such as sandblasting, polishing, drawing), chemical finishing (such as phosphating, pickling) and electrochemical finishing (such as electroplating, anodizing) as well as modern technologies such as physical vapor deposition (PVD) and chemical vapor deposition (CVD). These methods aim to improve the properties of metal surfaces such as corrosion resistance, wear resistance, electrical conductivity and aesthetics.

The Easiest Way To Blacken Metal?

One of the easiest ways to blacken metal is to use vinegar and baking soda. Mix an appropriate amount of baking soda and vinegar until foam forms, then apply this mixture to the metal surface that needs to be blackened and wipe it clean with a clean cloth. This method works on a variety of metals, such as aluminum, copper and stainless steel.

.jpg)