When discussing the field of CNC machining, a problem that has long troubled the industry is how to effectively control costs while maintaining high quality. You may face the following challenges:

Overpriced machining services that eat into your budget?

Low-cost options that result in poor-quality parts and production delays?

Hidden fees and unclear pricing structures that make budgeting impossible?

Many businesses struggle to find a supplier that provides precision, consistency, and affordability in one package. At VMT, we solve this problem by offering cost-effective, high-quality CNC machining solutions tailored to your needs.

High Quality

From prototyping to mass production, we deliver precision, reliability, and consistency in every part. Choose VMT for CNC machining excellence.

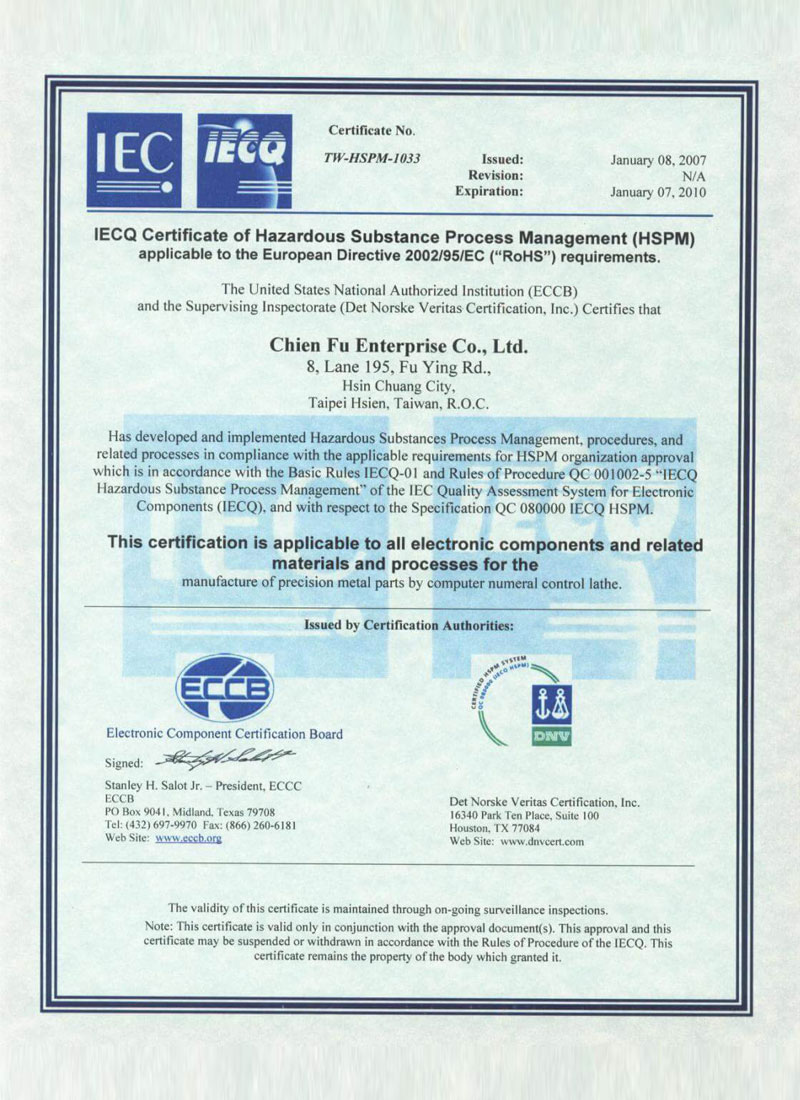

Strict Quality Control

Our ISO 9001:2015 & IATF 16949-certified facility follows CPK1.68-controlled processes, ensuring precision up to 0.01mm for every part.

High-Grade Materials & Finishes

We source only premium metals and plastics, offering a variety of coatings and treatments for enhanced durability.

Fast Turnaround

From prototyping to mass production, we deliver on time, every time—with express production available in as fast as 24 hours.

Continuous Improvement & Testing

Our team of engineers conducts rigorous material testing and performance evaluations to maintain the highest industry standards.