Struggling to choose between powder coating vs painting for your CNC parts? The wrong finish can compromise durability, appearance, or tolerance. Learn how to select the perfect CNC coating for your project.

This guide explains everything about CNC powder coating and CNC paint, including appearance, durability, cost, environmental impact, and thickness control. Discover which surface finish ensures your precision parts meet both aesthetic and functional requirements.

What Is Powder Coating for CNC Parts

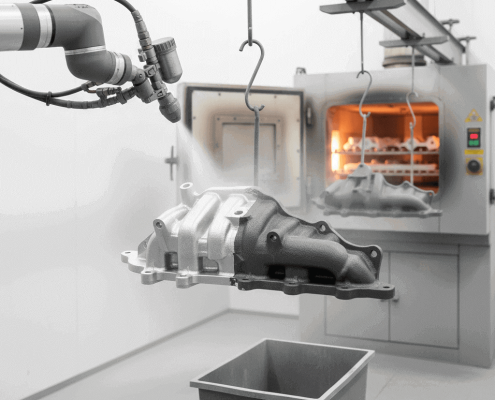

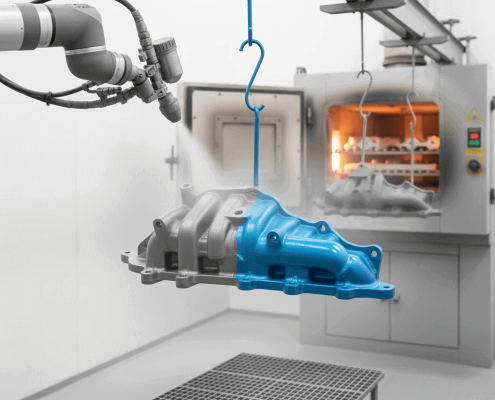

CNC powder coating is a dry finishing process that uses electrostatically charged powder particles. After spraying, the coated part is cured under heat, forming a dense and uniform layer. It’s a popular surface treatment for aluminum, steel, and stainless-steel components used in automotive, robotics, and industrial machinery.

This coating type offers excellent adhesion, high wear resistance, and corrosion protection. Unlike wet paints, it contains no volatile organic compounds, making it safer for both workers and the environment. The thick, matte surface of CNC powder coating also provides a premium feel—ideal for heavy-duty or outdoor parts where performance matters more than glossy appearance.

What Is Painting for CNC Parts

CNC paint is a liquid coating process applied with a spray gun, followed by drying or baking. It is widely used on metal and plastic components that demand aesthetic precision,such as consumer electronics, optical devices, and medical housings.

Painting allows for a vast range of colors and gloss levels, making it the go-to option when appearance and branding are priorities. The finish is thinner, smooth, and reflective, suitable for precision parts where every micron matters. However, traditional painting can release solvents and VOCs, requiring careful ventilation and environmental management.

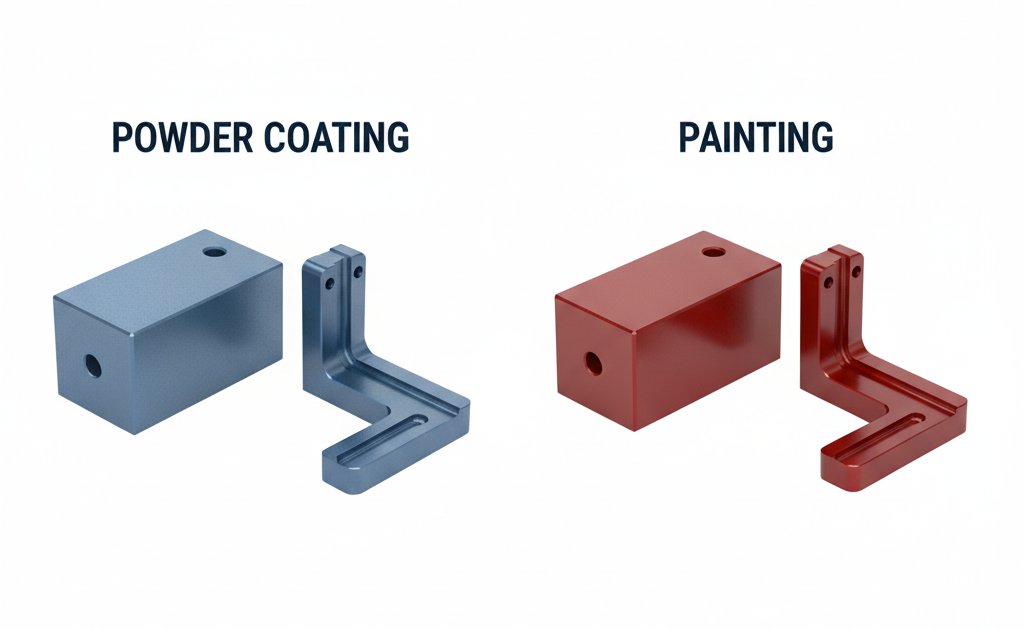

Surface Finish and Appearance

Powder Coating

CNC powder coating produces a consistent matte finish that conceals minor surface imperfections and delivers a strong, tactile texture. This coating enhances the industrial look of parts while providing a robust protective layer. It is particularly suitable for structural and mechanical CNC machined parts where strength and functionality are more important than glossy appearance.

Painting

CNC paint provides high-quality color control and a smooth, glossy surface. You can achieve metallic finishes, gradients, or brand-specific colors, making the components visually striking. This finish is perfect for consumer-facing parts, prototypes, or decorative elements where visual appeal is as critical as functionality.

Both coatings improve the surface quality of CNC parts, but their benefits differ. Use powder coating for durability and industrial aesthetics, and painting for precise color control and visually appealing finishes in CNC machining projects.

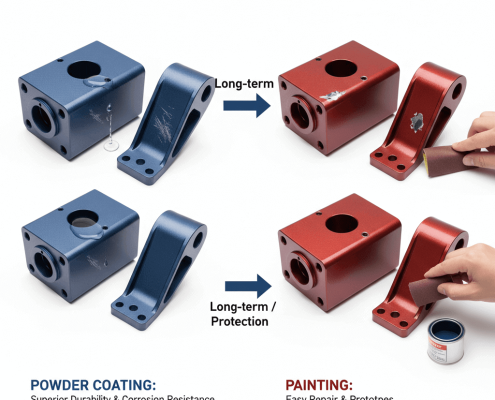

Durability and Corrosion Resistance

Powder Coating

CNC powder coating delivers superior durability due to its cross-linked molecular structure. It forms a tough, impact-resistant surface that protects against abrasion, chemical exposure, moisture, and ultraviolet light. This long-lasting performance is ideal for outdoor, mechanical, or industrial precision parts that require reliable protection over time.

Painting

CNC paint is less resistant to mechanical wear and environmental factors but offers ease of repair. Damaged or worn areas can be quickly sanded and repainted without reapplying the entire coating, which is advantageous for prototypes or parts with frequent design changes and shorter lifecycles.

For long-term protection and heavy-duty applications, powder coating is the preferred choice for CNC machined parts. Painting remains suitable for short-term projects, prototypes, or decorative components requiring easy maintenance and quick adjustments.

Cost and Production Efficiency

Powder Coating

The initial investment for CNC powder coating is higher due to the specialized curing equipment and powder application systems. However, it becomes cost-efficient for medium to large production runs because material waste is minimal and rework is rare. The process ensures consistent quality across multiple precision parts, making it ideal for larger batch production.

Painting

CNC painting has lower setup costs and requires simpler equipment. It is more economical for prototypes, small batches, and customized parts. Multiple colors can be applied and changed quickly, which is advantageous for low-volume production where flexibility and speed are important.

Both processes have their advantages depending on scale and requirements. Powder coating provides efficiency and consistency for large production volumes, while painting offers flexibility, lower initial cost, and faster customization for smaller CNC machining runs.

| Factor | Powder Coating | Painting |

| Setup Cost | Higher due to curing equipment | Lower using spray systems |

| Material Waste | Minimal, powder can be recycled | Higher, overspray is common |

| Batch Efficiency | Optimized for medium and large volumes | Best for small batches and prototypes |

| Lead Time | Slightly longer because of curing | Shorter and flexible for customization |

| Maintenance | Very low over time | Moderate to higher due to wear |

Environmental Impact

Powder Coating

CNC powder coating is environmentally friendly. It emits no volatile organic compounds and allows unused powder to be recovered and reused. This clean process aligns with sustainable manufacturing standards and is particularly suitable for industries requiring eco-compliant precision parts.

Painting

CNC paint can release harmful gases when using solvent-based coatings, although water-based alternatives reduce emissions. Painting still produces more material waste compared to powder coating, requiring careful environmental management to maintain compliance.

For environmentally conscious projects, powder coating is preferable. Painting remains a practical option for smaller-scale or decorative CNC machined parts, but sustainability considerations may influence the final choice.

Thickness and Precision Control

Powder Coating

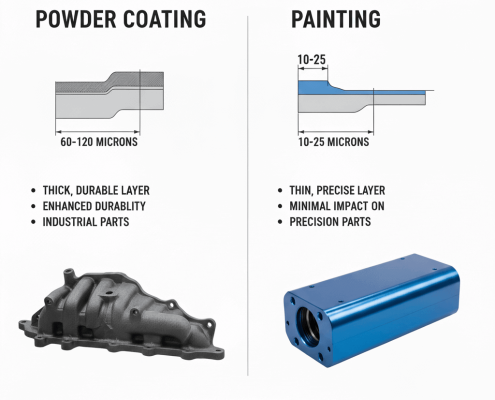

CNC powder coating typically creates a thick layer between sixty and one hundred twenty microns. This thickness enhances protection and durability but may affect parts with very tight tolerances. It is most suitable for structural, industrial, or mechanical CNC machined parts where protection outweighs micron-level precision.

Painting

CNC paint produces a thin, precise coating between ten and twenty-five microns. This ensures minimal impact on dimensional accuracy, making it ideal for precision parts such as optical mounts, robotics components, and instrument housings where even small deviations can affect assembly and functionality.

Choose powder coating for robust, durable finishes on industrial parts. Painting is optimal for CNC machining projects requiring thin, precise layers where tolerance and exact fit are critical.

Powder Coating vs Painting:Summary of the comparison

Here are the core distinctions across the main criteria that affect CNC coating quality and performance:

1.Appearance

Powder coating produces a durable, matte, and uniform surface suitable for industrial use. Painting achieves glossy, colorful finishes with more visual flexibility.

2.Durability

Powder coating provides long-lasting corrosion and impact resistance. Painting, while less durable, is easier to touch up or modify.

3.Cost

Powder coating requires higher setup investment but minimal maintenance. Painting is cheaper upfront and ideal for small, customized batches.

4.Environmental Impact

Powder coating emits no VOCs and minimizes waste. Painting produces solvent emissions and requires careful waste control.

5.Thickness & Precision

Powder coating’s thick layer may affect tolerances; painting ensures thin, even coverage for precision parts.

Here’s a clear summary comparing both finishes:

| Aspect | Powder Coating | Painting |

| Appearance | Matte, Uniform, Industrial Look | Glossy, Smooth, Decorative |

| Durability | High Corrosion & Impact Resistance | Moderate, Easier to Repair |

| Cost | Higher Setup, Lower Maintenance | Lower Setup, Higher Maintenance |

| Environmental Impact | VOC-Free, Recyclable | Solvent-Based, VOC Emissions |

| Thickness & Precision | 60–120 µm, May Affect Tight Tolerance | 10–25 µm, Ideal for Precision Parts |

Start Your Project at VMT

When you are ready to choose the best finish for your CNC parts, VMT offers expert guidance and precise execution. Whether you need CNC powder coating for durability or CNC paint for color accuracy and fine details, our team ensures your precision parts meet exact specifications. Contact us now and achieve both outstanding performance and perfect appearance.

Summary

Choosing between powder coating vs painting depends on your parts’ function, tolerance, and production scale. Powder coating excels in durability and corrosion resistance. CNC paint is ideal for high-precision, visually critical parts. Select the right finish to achieve the perfect balance of performance, appearance, and longevity.

Frequently Asked Questions

Can powder coating and painting be used on the same CNC machined part?

Yes. Some parts combine CNC powder coating for strength and CNC paint for decorative appearance. This hybrid approach balances durability, precision, and aesthetics.

2.Is it possible to repair or touch up powder-coated CNC parts?

Yes, but repair requires sanding or abrasive removal before recoating. CNC paint is easier to touch up, making it more convenient for prototypes or small-batch CNC parts.

What materials are not suitable for powder coating?

Materials with low heat resistance, such as certain plastics, rubber, or low-melting alloys like zinc or lead, are unsuitable for powder coating. The curing process requires high temperatures that can deform or damage these materials. For such components, liquid painting or other cold-applied coatings are better alternatives.