In today’s industrial age of extreme precision and miniaturization, are you facing difficulties in achieving machining accuracy, meeting delivery deadlines, or experiencing unsatisfactory surface finishes for micro parts? These challenges not only impact product performance but can also delay your market entry.

However, micro CNC machining is a good solution. Micro CNC machining is a high-precision manufacturing process used to create intricate components with extremely tight tolerances, often down to ±0.005mm. We at VMT understand the critical demand for unparalleled precision and reliability in modern manufacturing. As a leading micro machining CNC factory, we consistently deliver components that meet the most stringent specifications.

Our expertise spans the entire micro CNC machining process, from initial design consultation to final delivery. We aim to empower your projects with components manufactured to the highest standards. This guide offers an in-depth look into the capabilities, processes, and commitment required for successful micro CNC machining.

What is Micro CNC Machining?

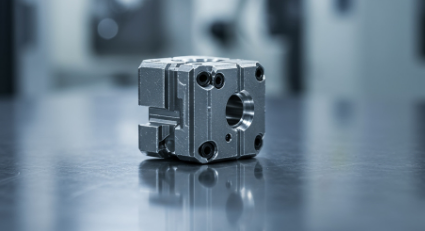

Micro CNC machining utilizes specially designed micro-tools and high-precision CNC machine tools to perform high-precision cutting operations on parts typically less than 1 mm in size, down to the micron level. Micro CNC machining specializes in machining extremely small components with extremely tight tolerances and is the cornerstone of the functionality of countless high-tech products.

At its core, it relies on precise control of extremely small features, which requires machine tools with ultra-high positioning accuracy and repeatability. It leverages advanced multi-axis CNC machines, Swiss-type lathes, and sophisticated quality control systems to produce parts for industries such as aerospace, medical, and electronics. Key benefits include the ability to produce complex geometries, superior surface finishes, and consistent repeatability, addressing critical demands for miniature and high-performance components

Micro CNC Machining vs Traditional CNC Machining

When comparing micro CNC machining with traditional CNC machining, the key differentiator lies in precision and scale. Micro CNC machining is designed to achieve unprecedented accuracy, enabling the production of features at the micron level. This makes it ideal for industries where even the smallest deviation can compromise performance, such as medical devices, aerospace, and advanced electronics.

Unlike traditional CNC machining, which is optimized for larger parts and general applications, micro CNC systems employ ultra-fine tools and vibration-minimized setups to deliver consistent, repeatable results. This allows manufacturers to reproduce complex geometries with superior surface finishes and tighter tolerances.

| Feature | Micro CNC Machining | Traditional CNC Machining |

|---|---|---|

| Minimum Feature Size | Typically < 100 microns | Typically > 500 microns |

| Tolerance Capability | ± 1–10 microns | ± 25–100 microns |

| Surface Finish (Ra) | Often < 0.2 µm | Often 0.4 – 1.6 µm |

| Tool Diameter | < 1 mm (often < 0.1 mm) | > 1 mm |

| Typical Part Size | Millimeter to sub-millimeter scale | Centimeter to meter scale |

| Primary Application | Medical, electronics, aerospace | Automotive, industrial, general |

How Does the Micro CNC Machining Process Work from Design to Delivery?

Successfully managing a micro CNC machining project requires a carefully structured workflow. Each stage, from the initial design to final quality checks and delivery, plays a vital role in ensuring precision, consistency, and reliability.

1. Design Optimization and DFM

The first step of a micro CNC machining project is thoughtful design. At this stage, engineers evaluate critical factors such as wall thickness, aspect ratios, and feature accessibility to confirm that the part can be manufactured efficiently. Overly complex geometries often increase both cost and production difficulty. By working with experienced CNC engineers during the design stage, it becomes possible to conduct Design for Manufacturability reviews. These reviews help identify potential risks and simplify production, reducing the likelihood of costly revisions.

2. Material Selection and Preparation

Choosing the right material is essential for both performance and machinability. Common choices for micro CNC machining include titanium, stainless steel, aluminum, advanced polymers, and ceramics. Each material behaves differently, with properties such as hardness, brittleness, and thermal conductivity influencing the machining strategy. Material preparation, including verifying purity and stability, helps to prevent defects during cutting and supports high-precision results.

3. Advanced Machining Techniques and Multi-Axis Systems

Micro CNC machining relies on advanced multi-axis systems that allow for sub-micron positioning accuracy and ultra-high spindle speeds. Five-axis and seven-axis machines are frequently used because they enable access to complex geometries without requiring multiple setups, which reduces alignment errors. These machines are typically housed in controlled environments that minimize vibration and thermal variations. Cutting strategies such as high-speed milling with shallow depths of cut protect both tool life and surface finish. Together, these methods make it possible to achieve the accuracy demanded by micro-scale components.

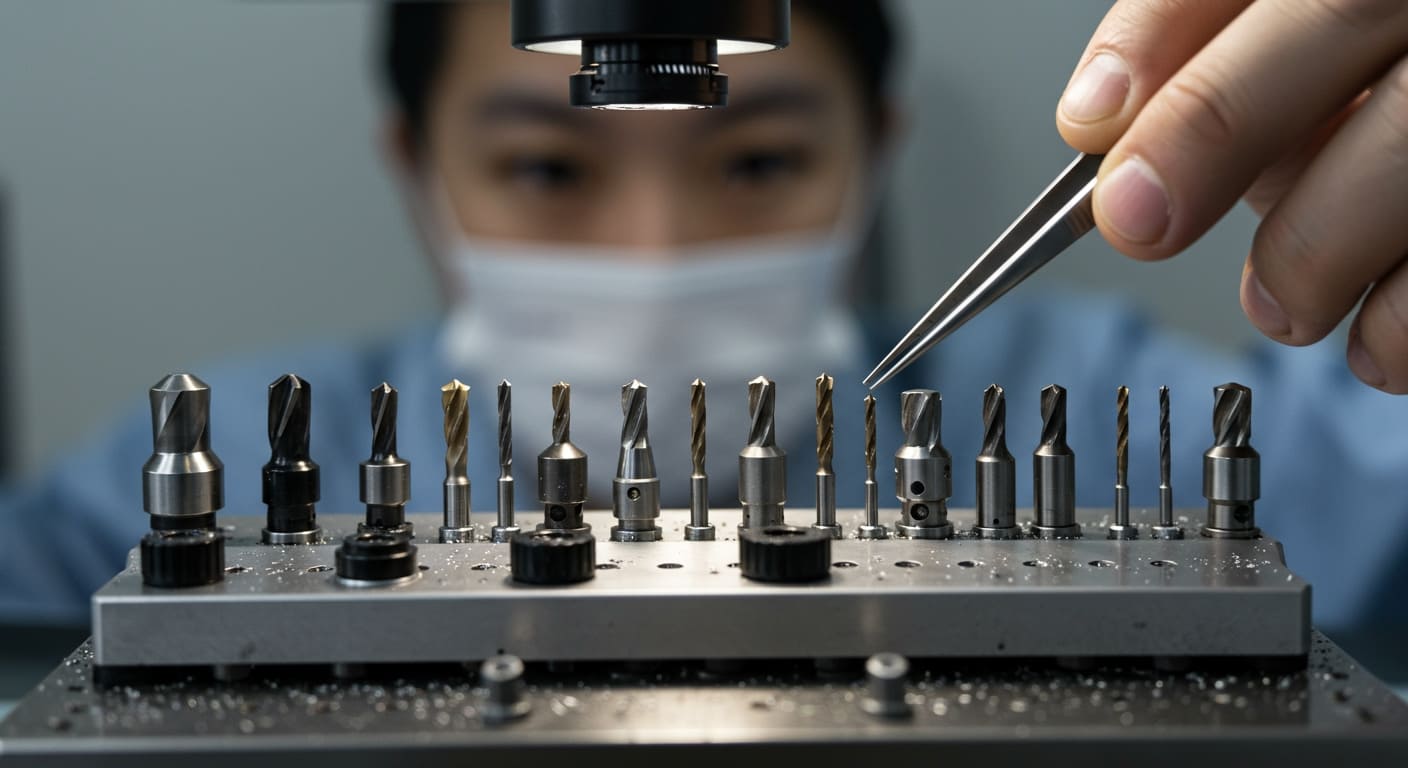

4. Specialized Tooling and Workholding Solutions

The tools used in micro CNC machining are extremely small, often less than one millimeter in diameter and sometimes smaller than 0.1 millimeter. Maintaining tool sharpness and preventing tool deflection are essential for creating accurate features. Workholding presents an additional challenge because fragile or thin-walled parts can deform if not handled carefully. To address this, manufacturers use specialized fixtures or vacuum-based systems that secure parts firmly without causing distortion during the machining process.

5. Process Monitoring and In-Process Adjustments

Once machining begins, close monitoring of the process is necessary to maintain quality. Sensors track variables such as vibration, spindle load, and temperature in real time. This information allows operators to make immediate adjustments, such as modifying spindle speeds or feed rates, to prevent tool breakage and maintain tolerance levels. In-process monitoring ensures consistency across production runs and reduces the risk of errors going unnoticed.

6. Quality Control and Metrology

Quality assurance is a critical element of micro CNC machining. Inspection begins with raw material verification and continues through in-process checks to final validation. Because contact-based measurement methods are not always suitable for micro features, non-contact metrology tools such as optical profilometry, laser scanning, and scanning electron microscopy are commonly used. These methods provide extremely accurate assessments of surface finish, critical dimensions, and micro-feature integrity. By establishing strict quality gates at every stage, manufacturers reduce scrap, minimize rework, and deliver reliable parts.

7. Final Delivery and Documentation

The final stage of the process involves preparing components for delivery. This includes cleaning, careful packaging, and thorough documentation. In industries such as aerospace, electronics, and medical devices, customers expect certificates of compliance, traceability records, and detailed inspection reports. Providing this documentation ensures that every part meets strict regulatory and performance standards, giving customers confidence in both the quality and reliability of the final product.

Summary of the Micro CNC Machining Process

| Stage | Description | Key Focus Areas and Tools |

|---|---|---|

| Design Optimization and DFM | Ensure manufacturability by reviewing geometry and simplifying where necessary. | Wall thickness, aspect ratios, DFM collaboration |

| Material Selection and Preparation | Choose materials that balance machinability and performance requirements. | Metals, polymers, ceramics, stability preparation |

| Advanced Machining Techniques | Apply multi-axis systems in controlled environments to achieve precision cutting. | Five-axis and seven-axis machines, high-speed milling, micro-tools |

| Specialized Tooling and Workholding | Use ultra-fine tools and secure fragile parts without distortion. | Sub-millimeter tools, custom fixtures, vacuum systems |

| Process Monitoring and Adjustments | Track real-time variables to maintain accuracy and prevent tool failure. | Sensors, vibration monitoring, spindle load tracking |

| Quality Control and Metrology | Inspect using advanced non-contact tools to verify accuracy at the micro scale. | Optical profilometry, SEM, laser scanning |

The Advantages and Disadvantages of Micro CNC Machining

Micro CNC machining offers unmatched precision and flexibility for producing miniature, high-performance components. However, it also presents technical challenges that require specialized expertise and equipment. The following summarizes the main advantages and disadvantages.

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Precision and Accuracy | Achieves feature sizes in the tens of microns with positional accuracy in the single-digit micron range. Ensures consistent replication of complex designs, reducing errors and improving reliability. | Maintaining micron-level tolerances is highly challenging. Thermal expansion, vibration, and tool deflection must be carefully controlled. Requires climate-controlled environments and advanced metrology. |

| Material Utilization | Minimizes waste due to small part sizes and efficient cutting strategies. Especially beneficial with costly or exotic materials. Supports sustainable and cost-effective production. | Material selection is critical. Some materials behave unpredictably at micro scale, causing issues like chipping, galling, or deformation. Expert knowledge is required to choose suitable materials. |

| Production Efficiency | Ideal for small-batch or prototype production. Rapid changeovers and digital control allow customization without extensive retooling. Enables faster lead times and agile product development. | Less suited for high-volume, large-scale manufacturing. Setup and monitoring require skilled operators, increasing labor and training costs. |

| Surface Finish and Quality | Delivers ultra-smooth surfaces with Ra values often below 0.2 µm. Supports advanced applications in medical, aerospace, and electronics. | Surface finish is sensitive to cutting parameters. Burrs, micro-cracks, or integrity issues may occur. Post-processing such as micro-polishing or cleaning may be necessary. |

| Tooling and Equipment | Utilizes ultra-fine tools and multi-axis machines for accessing complex geometries. Ensures delicate parts are secured with specialized fixtures. | Tools are extremely fragile and wear quickly. Equipment investment is high, and maintenance requires strict control to ensure performance. |

Specialized Surface Finishing for CNC Micro-Machining Parts

Surface finishing is a key step in CNC micro-machining, ensuring that parts not only meet functional standards but also achieve the desired durability and appearance. Below are several specialized finishing techniques commonly applied to micro CNC components.

1. Anodizing and Hard Anodizing

Anodizing is widely used for aluminum components to increase corrosion resistance while providing decorative surface options. Hard anodizing takes the process further, creating a denser and more wear-resistant oxide layer. These treatments are particularly valuable in aerospace and medical applications where both strength and appearance matter.

2. Micro-Arc Oxidation (MAO/PEO)

Micro-Arc Oxidation, also known as Plasma Electrolytic Oxidation (PEO), produces a ceramic-like surface layer that delivers exceptional hardness, wear resistance, and insulation properties. This technique is ideal for components that operate in extreme environments, offering long-term protection and stability.

3. Sandblasting and Wire Drawing

Sandblasting and wire drawing are mechanical surface treatments that modify texture for both functional and aesthetic purposes. Sandblasting creates a matte, uniform finish that enhances paint or coating adhesion, while wire drawing gives the part a linear grain that improves its appearance. These treatments are often used when visual quality is a priority.

4. Polishing and Electropolishing

Polishing and electropolishing refine surfaces to achieve extremely smooth finishes with reduced roughness values. These processes are essential for medical implants, optical devices, and precision instruments where surface cleanliness and smoothness directly influence performance and safety.

5. Electroplating and Conductive Oxidation

Electroplating deposits a thin layer of metal, such as gold, nickel, or chrome, onto the part surface, improving conductivity, appearance, and corrosion resistance. Conductive oxidation enhances electrical performance by creating controlled oxide layers. Both treatments are valuable in electronic and aerospace applications where conductivity and protection are critical.

6. Passivation

Passivation is commonly applied to stainless steel components to remove free iron and other contaminants from the surface. This chemical treatment strengthens the natural corrosion resistance of the alloy without altering its mechanical properties, making it ideal for medical, food-grade, and industrial applications.

7. PVD Coating and Heat Treatments

Physical Vapor Deposition (PVD) creates thin, hard coatings that enhance wear resistance, surface hardness, and visual appeal. Heat treatments, on the other hand, improve mechanical strength and fatigue resistance by altering the internal microstructure of the material. Both processes extend the operational lifespan of micro CNC machined parts.

We collaborate with more SQE-audited professional surface treatment factories to provide a diverse range of finishing processes. This extensive network ensures that we can meet virtually any surface requirement for your micro machining CNC components.

Partnering for Excellence in Precision CNC Micro Machining

At VMT, we are dedicated to setting the benchmark for precision, quality, and reliability in micro CNC machining. Our robust infrastructure, advanced machinery, and rigorous quality control systems ensure every component we produce meets your exacting standards.

Whether you require intricate aerospace CNC micro machining parts or high-volume traditional CNC micro machining parts, our expertise is at your disposal. We invite you to experience the VMT difference. Let us transform your designs into perfectly realized physical components with our superior micro machining CNC capabilities.

Contact us today to discuss your next micro CNC machining project.

In Conclusion

Micro CNC machining is an indispensable technology for industries demanding the highest levels of precision and intricacy in miniature components.

From tight tolerance demands to critical surface finishes and reliable after-sales support, partnering with an experienced provider, like us, is essential. Our expertise ensures your projects are not only completed to exact specifications but also delivered efficiently with consistent quality.

Frequently Asked Questions About Micro CNC Machining

What Defines Micro CNC Machining Compared to Traditional CNC Machining?

Micro CNC machining specializes in creating extremely small and intricate components with sub-millimeter features and exceptionally tight tolerances, often in the micron range. Traditional CNC machining typically handles larger parts with less stringent precision requirements. The process often involves specialized micro tools, higher spindle speeds, and sophisticated control systems.

What are the Typical Applications and Potential CNC Micro-machining Parts?

Micro CNC machining is crucial for industries requiring miniature, high-precision components. Common applications include medical devices (surgical instruments, implants), aerospace (sensor housings, miniature connectors), electronics (micro-optics, semiconductor components), and telecommunications. Potential CNC micro-machining parts include microfluidic devices, optical mounts, tiny gears, and complex probes.

How does VMT Ensure the High Precision Required for Useful CNC Micro Machining Parts?

VMT achieves high precision through a combination of advanced equipment, a temperature-controlled environment, and a stringent 12-stage quality control process. We utilize multi-axis CNC machines and Swiss-type lathes, capable of delivering dimensional tolerances as fine as ±0.005mm and geometric tolerances within 0.01mm. Our DFM consultations and in-process inspections further ensure adherence to specifications.

What is VMT’s Approach to Managing Lead Times for Complex Micro Machining CNC Projects?

We employ agile manufacturing principles to manage lead times effectively. Standard parts are delivered within 7 days, while non-standard or complex micro machining CNC projects have a lead time of 25 days. For urgent requirements, we offer an expedited 10-day delivery service. Our structured internal processes and efficient workflow minimize delays.

Can VMT Handle Specialized Surface Treatments for Various CNC Micro-machining Parts?

Yes, VMT has an extensive network of over 50 SQE-audited professional surface treatment partners, enabling us to offer a wide array of finishing options. This includes anodizing, hard anodizing, PVD, electropolishing, and heat treatments. We also possess specialized expertise in critical processes like hard anodizing dimension pre-reservation and resolving material streaking issues for alloys like 7075, particularly important for aerospace CNC micro machining parts.

-80x80.jpg)