How to Make Custom Metal Parts – A Complete Guide

Metal, the core material of many industries and household items, has brought us many amazing devices with its excellent performance, which has greatly enriched our lives. Since entering the industrial age, metal processing technology has developed into a profound science. The Industrial Revolution has greatly promoted the large-scale development of modern metal processing technology, and at the same time, the technologies used in these processes have become increasingly complex.

Among them, CNC machining technology has become the preferred solution to meet diverse needs due to its ability to quickly and accurately manufacture metal parts of various shapes and sizes according to the specific needs of customers. This guide is designed to help readers gain a deep understanding of various metal machining methods so that everyone has a basic understanding of metal machining.

What is Metalworking?

Metalworking refers to a series of operations on metal materials to change their shape, size, properties or surface state in order to meet specific product design, manufacturing and use requirements. This process may include a variety of techniques such as casting, forging, welding, cutting and heat treatment. Through these techniques, metal materials can be processed into the desired shape and size, while adjusting their physical and chemical properties such as hardness, strength, corrosion resistance, etc.

Types of Metal Materials

There are many types of metal materials, each of which has its own unique properties and uses and is widely used in various fields.

Commonly used metals and metal alloys include:

- Iron

- Stainless steel

- Copper

- Magnesium

- Aluminum

- Titanium

How to Make Custom Metal Parts?

There are many ways to make custom metal parts, each of which has its own specific application scenarios and process characteristics. The following is a brief introduction to several commonly used processing methods.

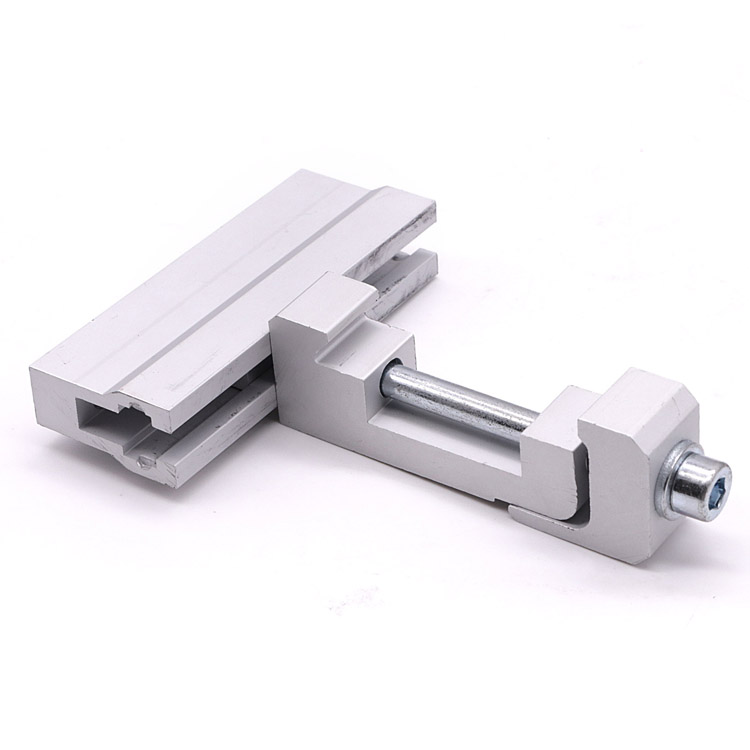

CNC Machining: Material Removal.

CNC machining is a highly automated metal processing technology that uses a machine tool’s rotating tool or grinder to remove excess material from metal parts through precise tool paths and cutting parameters to obtain the desired shape and size. This method is suitable for machining metal parts of various complex shapes and precisions, such as automotive parts, aerospace parts, etc., with the characteristics of high precision and high efficiency.

Extrusion: Shaping of Materials.

Extrusion applies pressure to metal through a die to cause it to undergo plastic deformation. It is mainly used to produce solid or hollow metal parts with the same cross-sectional shape, such as pipes, bars, etc. The extrusion process has the advantages of low cost and high production efficiency, and is particularly suitable for mass production.

Forging: Hammering of Material Into Shape.

Forging is a processing technology that causes metal to undergo plastic deformation by hammering or pressure. It can produce metal parts with complex shapes and high strength, such as gears, shafts, etc. The forging process includes two forms: free forging and die forging. Die forging has higher precision and surface quality, and can meet the strict requirements for part strength and precision.

Casting: The Material is Melted and Poured Into a Mold to Form the Shape.

Casting is a processing method that melts metal and injects it into a mold, and then cools and solidifies it to obtain metal parts of the desired shape and size. Casting processes include sand casting, investment casting, injection casting, die casting and other methods, which are suitable for the production of large and complex metal parts.

Stamping: Material is Pressed Into Shape Through a Die.

Stamping is a processing method that applies pressure to metal sheets through a die to cause plastic deformation and separate metal parts of the required shape and size. The stamping process includes bending, drawing, punching, trimming and other processes, and is suitable for the production of thin plate parts and parts with complex shapes. Stamping parts have high dimensional accuracy and surface quality, and high production efficiency, and are widely used in the fields of automobiles, electronics, home appliances, etc.

Die Casting: The Material is Melted and Injected Into a Mold Under High Pressure to Form the Shape.

Die casting is a processing method that melts metal and injects it into a mold under high pressure, and then cools and solidifies it to obtain metal parts of the desired shape and size. It is suitable for producing metal parts with thin walls and complex shapes, such as automotive parts and electronic product housings. Die-cast parts have high dimensional accuracy and surface quality, and can produce parts with complex internal structures, meeting the requirements for part accuracy and complexity.

Rolling: Shaping of Materials

Rolling is a pressure processing method in which a metal billet is passed through the gap between a pair of rotating rollers, where the material is compressed by the rollers to reduce its cross-section and increase its length. This is the most common production method for steel, mainly used to produce profiles, plates, pipes, etc.

Common Machines in Metalworking Tools.

There are many types of machines commonly found in metalworking tools, each with its own specific uses and processing capabilities. Here are some common metalworking machines:

- Milling Machine

- lathe

- Punch

- Hydraulic Press

- laser Cutting Machine

- Plasma Cutting Machine

- Welding Machine

- Bending Machine

- Grinder

- Polishing Machine

Surface Treatment Options For Metal Parts

As the finishing step in the manufacturing process, surface treatment of metal parts not only adds environmental protection and aesthetic characteristics, but also significantly improves surface roughness control, corrosion resistance and other performance that exceeds the capabilities of traditional machining. Furthermore, some surface treatment technologies can also enhance the mechanical strength and electrical properties of metal parts.

Here are some key metal part surface finishing options:

Electroplating: Through electrolysis, a layer of metal or alloy, such as chromium, nickel, etc., is deposited on the surface of parts to enhance conductivity, wear resistance and corrosion resistance.

Chemical Plating: No external power source is required. A metal or alloy layer is formed on the surface of the part through chemical reaction. It is suitable for complex shapes and precision parts.

Anodizing: Generates a dense oxide film on the surface of aluminum alloy parts to improve wear resistance and corrosion resistance.

Vacuum Plating: Electroplating in a vacuum environment can produce a higher quality and more uniform coating.

Hot Dip: Dipping parts into molten metal creates a metallic coating that provides excellent corrosion protection.

Painting: Use paint or powder coating to evenly cover the surface of parts, providing an aesthetically pleasing appearance and protection against corrosion and wear.

Thermal Spraying: Spraying materials onto the surface of parts at high temperatures to form a protective layer or functional layer.

Polishing: can significantly reduce surface roughness and improve the appearance and smoothness of parts.

Brushed Finish: Gives metal parts a unique non-mirror metallic sheen and is often used in decorative applications.

Phosphating Treatment: By forming a phosphate chemical conversion film on the surface of parts, its wear resistance, corrosion resistance and adhesion are enhanced.

Choose VMT to Process Your Metal Parts.

VMT has over 14 years of experience in metal CNC machining, equipped with 66 multi-axis CNC machines, 30 CNC machines, 20 automatic lathes, and high-precision measuring equipment. Our 120-person production team can produce 2,000 sets of exterior parts per day. With our advanced CNC machines and programming technology, we are able to quickly and accurately manufacture metal parts of various shapes and sizes to meet the diverse needs of our customers. At the same time, we also provide a comprehensive surface treatment service to ensure that the quality and performance of the parts meet the requirements.

In Conclusion.

Metals play a vital role in many industries and household products. The equipment they create greatly facilitates our lives, making them more comfortable and beautiful. In modern manufacturing, the machining and customization of metal parts occupies an irreplaceable position. This article provides a comprehensive guide to metal parts processing methods, so you can choose the most suitable processing method to customize metal parts.

Frequently Asked Questions About Metalworking

What are The Six Most Common Types of Metalworking?

The six most common types of metalworking include casting, forging, stamping, machining, powder metallurgy, and injection molding.

Is Metalworking the Same as Welding?

Metalworking and welding are not the same. Metalworking is a broad process that includes various methods and techniques used to transform raw metal materials into final metal products, such as cutting, forming, assembling, etc., while welding is just one of many steps in the metal assembly process used to assemble a product.

How is Metal Machining Technology Used Today?

Metal machining technology plays a key role in the manufacturing industry and is widely used in many industries such as automobiles, aerospace, electronics and machinery manufacturing to produce various key components and structural parts. At the same time, metal processing technology is also favored by artists and craftsmen, who use casting, forging, stamping and other processes to create exquisite works of art such as sculptures, accessories, and furniture.