How Can I Ensure the Dimensions of Parts After Hard Anodizing?

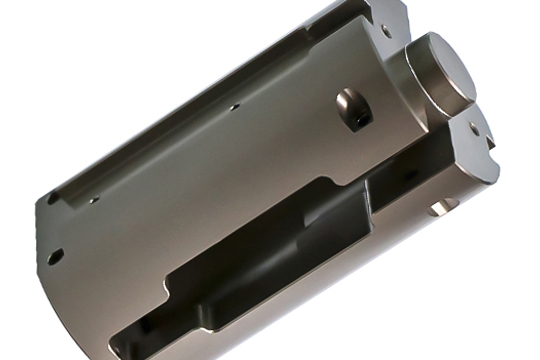

In precision CNC machining, maintaining accurate dimensions after hard anodizing is critical. This surface treatment significantly enhances the durability and corrosion resistance of aluminum parts, but it also alters their size. Without properly accounting for these changes, components may fall out of tolerance, leading to assembly issues or rework.

Unlike standard anodizing, which typically results in slight material reduction, hard anodizing causes dimensional growth due to a thicker oxide layer. For applications like optical CNC parts, aerospace assemblies, or high-precision housings, it’s essential to predict and compensate for these shifts during the CNC machining process.

Dimensional Changes After Anodizing

Anodizing is an electrochemical process that creates a protective oxide layer on the surface of aluminum and its alloys. This process fundamentally changes the dimensions of the part, which is a critical consideration for any precision manufacturing.

How Dimensional Changes Occur?

Anodizing doesn’t just add a coating to the surface; it converts the outer layer of the aluminum itself into aluminum oxide. Aluminum oxide is less dense than the original aluminum, so it takes up more space. As a result, the part’s dimensions slightly increase.

The growth of the oxide film happens in two directions: inward and outward. Part of the film penetrates into the base metal, while the other part builds up on the original surface.

- The outside diameter (OD) of a part will increase because the film grows outward.

- The inside diameter (ID) of a hole or a threaded feature will decrease because the film grows inward.

Different Anodizing Types and Their Impact

The amount of dimensional change depends heavily on the type of anodizing and the process parameters. A general rule of thumb is that roughly half of the total anodized film thickness penetrates into the material, while the other half builds on the surface. Therefore, the dimensional growth on a single surface is approximately half of the total film thickness.

- Standard Anodizing (Type II):

- This process typically produces a film thickness of microns.

- The dimensional growth is often considered to be about to of the total film thickness. For a -micron film, a single surface might see a growth of microns.

- Hard Anodizing (Type III):

- This type creates a thicker, denser film, usually between microns or more.

- The dimensional growth is more significant and is often considered to be about of the total film thickness. For a -micron hard anodized film, a single surface would grow by approximately microns.

- Due to the substantial thickness, hard anodizing’s impact on dimensions must be carefully factored into the design and machining stages.

How to Control Final Dimensions?

1. Adjust CNC Machining Dimensions Based on Anodizing Growth

To ensure final dimensional accuracy, it’s crucial to pre-compensate for changes introduced by anodizing. For hard anodizing, For hard anodizing, we generally increase the size of the single side of the material above 40um by 0.008-0.012mm, and reduce the size of the single side of the material by about 0.01MM for ordinary oxidation. The material of the parts is increased or decreased accordingly.

These figures depend on the acid soaking cycle and anodizing duration applied by the oxidation facility. Raw part dimensions should be programmed accordingly during CNC roughing and finishing stages to maintain tolerance post-treatment.

2. Coordinate with the Anodizing Provider’s Specifications

Different surface treatment vendors operate with varying acid concentrations, bath chemistries, and exposure times. Before production, confirm the expected oxide thickness and growth profile to set proper machining allowances. Close collaboration ensures consistency and avoids unnecessary dimensional deviations.

3. Use Accurate Tool Offsets During CNC Finishing

In high-precision machining, especially for tight-tolerance holes, fits, and mating surfaces, apply calculated toolpath offsets during final passes. This ensures critical dimensions remain within spec even after anodizing-induced growth or shrinkage.

4. Perform Dimensional Inspection After Surface Treatment

Once anodizing is completed, validate critical features using CMMs, bore gauges, or pin gauges. Post-treatment inspection helps confirm whether programmed allowances matched the actual anodizing behavior, enabling closed-loop process refinement.

5. Select Consistent Aluminum Alloys

Materials like 6061-T6 aluminum are widely favored for their dimensional stability, surface finish quality, and compatibility with both CNC machining and anodizing. For applications involving optical components or aesthetic surfaces, such alloys provide superior color uniformity and minimal warpage, ensuring both mechanical and cosmetic performance.

In Conclusion

Controlling final dimensions after anodizing is essential for maintaining the quality and functionality of CNC machining parts. By understanding how anodizing affects surface thickness, whether through growth in hard anodizing or reduction in standard anodizing, engineers and machinists can apply accurate machining offsets and design allowances.

Collaborating with surface treatment vendors, using precise toolpath adjustments, performing thorough post-anodizing inspection, and selecting stable alloys like 6061-T6, when these practices are integrated into your CNC workflow, they ensure that critical dimensions remain within tolerance even after surface finishing, enabling reliable performance in both functional and cosmetic applications.