Fryer M21 CNC Code: A Comprehensive Guide

Many CNC operators feel lost when first encountering the Fryer M21 control system. Without proper training, errors multiply, productivity drops, and machine downtime increases. Worse, poor-quality parts risk customer trust and delay delivery.

This guide delivers a complete walkthrough of the Fryer M21 CNC Code Siemens Free, with intuitive explanations for all core functions. Whether you’re a beginner or aiming to master advanced programming, you’ll find the structure, syntax, and tips you need to optimize performance.

What is Fryer M21 CNC Control?

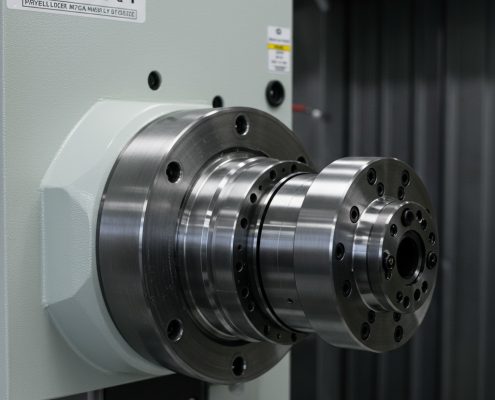

The Fryer M21 CNC control system is an advanced hybrid interface developed by Fryer Machine Company, utilizing Siemens’ reliable control architecture. This system is designed to offer a seamless blend of user-friendly operation and high-performance capabilities, making it accessible to both novice and experienced operators. The M21’s intuitive touch-screen interface and conversational programming simplify the machining process while providing robust functionality for complex tasks.

Built to serve a variety of demanding industries, including automotive machining, medical prototyping, and aerospace precision parts manufacturing, the M21 stands out for its versatility and efficiency. It supports advanced customization, allowing manufacturers to tailor processes to specific needs, and features high-speed processing for optimized cycle times.

Understanding G-Code and M-Code in Fryer M21

The Fryer M21 CNC control system uses G-code and M-code as its fundamental programming languages, enabling precise control of machining operations. G-code primarily defines the movements and positioning of the machine, such as linear and circular motions, while M-code is responsible for auxiliary functions, including tool changes, coolant control, and spindle activation. For Fryer M21:

- G00 = Rapid positioning

- G01 = Linear feed

- M03 = Spindle on (clockwise)

- M06 = Tool change

In the context of the Fryer M21, these codes are seamlessly integrated into its conversational programming system, making it easier for operators to implement complex machining sequences. Key features include the ability to edit and simulate G-code programs in real time, providing an intuitive interface for both manual and automated programming tasks.

M21 Control System Structure Based on Siemens Logic

The M21 control system leverages Siemens’ industrial-grade logic, combining a user-friendly graphical interface with robust code compatibility. Supporting standard G-code and M-code, it ensures seamless integration with other Siemens platforms and simplifies the transition for operators. Its high responsiveness and real-time processing optimize production efficiency and precision.

With extensive interface customization, the M21 allows manufacturers to tailor workflows and automate tasks, enhancing flexibility and control. Integrated diagnostic tools and real-time simulation reduce downtime, making the system highly reliable and ideal for demanding industries like aerospace, automotive, and medical manufacturing.

What Are the Essential G-Codes for Operating the Fryer M21?

G-codes are the foundational commands used to control the movements and operations of CNC machines, including the Fryer M21. They dictate the motion paths, coordinate settings, and machine configurations. Understanding the essential G-codes ensures efficient programming and smooth operations. Below is a list of key G-codes and their functions:

| G-Code | Function |

|---|---|

| G00 | Rapid movement |

| G01 | Linear interpolation |

| G02 | Clockwise circular motion |

| G03 | Counterclockwise circular motion |

| G17-G19 | Plane selection |

| G20/G21 | Inch/mm mode |

| G28 | Return to home |

How Do I Get Started with CNC Programming for the Fryer M21?

To effectively begin CNC programming for the Fryer M21, follow these steps:

1. Familiarize with System Architecture

Begin by understanding the Siemens-based control architecture of the Fryer M21. Study Siemens CNC manuals and M21-specific controller guides to gain a solid foundation. These resources will help you grasp the capabilities and nuances of the control system.

2. Leverage Simulation Tools

Utilize simulation tools such as Sinutrain to practice programming in a virtual environment. These tools replicate the Fryer M21’s operation environment, allowing you to experiment safely while learning key programming and operational concepts.

3. Start with Beginner-Friendly CAM Software

Using CAM software like Fusion 360 can simplify the programming process. These tools automatically generate G-code for a variety of machining tasks, making it easier for beginners to transition into CNC programming.

4. Practice with Sample Programs

Start by analyzing and editing basic sample programs to familiarize yourself with G-code and M-code syntax. Pay attention to machine coordinate systems, tool paths, and setup configurations as these are essential for accurate machining.

5. Master Basic Machine Operations

Learn to set up tool offsets and define workpiece origins accurately. Always perform thorough safety checks to minimize errors and ensure safe operation during the machining process.

6. Test in Simulation Mode

Before executing your program on the machine, test it in simulation mode to identify and correct any potential issues. This ensures the program runs smoothly and builds your confidence in operating the Fryer M21.

Commonly Used Fryer M21 CNC Codes

M-codes, or Miscellaneous Codes, are essential in controlling auxiliary machine functions on the Fryer M21. These codes manage tasks such as spindle activation, tool changes, and coolant control, complementing G-code instructions to execute a complete machining process. Below is a table of commonly used M-codes and their functions:

| M-Code | Function |

|---|---|

| M03 | Spindle on (Clockwise) |

| M04 | Spindle on (Counterclockwise) |

| M05 | Spindle stop |

| M06 | Tool change |

| M08 | Coolant on |

| M09 | Coolant off |

| M30 | Program end & reset |

Tips for Beginners Using Fryer M21

Starting out with the Fryer M21 CNC system can be challenging, but following some best practices will help you work more efficiently and safely. The tips below focus on key habits and resources that can improve your programming and machining experience.

1. Always Simulate Before Running

Running a complete simulation before actual machining helps identify errors, tool collisions, or unexpected behaviors. This precaution minimizes the risk of damaging the machine or the workpiece, ensuring safer and more accurate operations.

2. Label Your Toolpaths Clearly

Clear and consistent labeling of toolpaths and program sections improves program readability. It simplifies troubleshooting and program modifications, making the machining process easier to monitor and adjust as needed.

3. Use Fryer M21 CNC Code Siemens Free Samples for Reference

Taking advantage of free sample programs designed for the Fryer M21 and Siemens control systems offers valuable insights. These references demonstrate proper coding techniques and common practices, helping beginners accelerate their learning curve.

4. Keep a Backup of Offset Tables

Regular backups of tool and work offset tables are essential. They protect your setup data from accidental loss or system resets, enabling quick recovery and reducing machine downtime.

Comparing Fryer M21 to Other CNC Controllers

When choosing a CNC controller, it’s important to consider how the Fryer M21 stacks up against popular alternatives like FANUC and HAAS. Each system offers different strengths in terms of user interface, customization options, learning curve, and software support. The table below summarizes these key differences to help manufacturers select the best fit for their needs:

| Feature | Fryer M21 | FANUC | HAAS |

|---|---|---|---|

| UI Simplicity | High | Medium | High |

| Customization | Siemens-based | Proprietary | Proprietary |

| Learning Curve | Moderate | High | Low |

| Post Support | Siemens-friendly | Widely available | HAAS-specific |

Error Handling and Troubleshooting

Effective error handling is crucial for maintaining smooth operation of the Fryer M21 CNC controller. Understanding common alarms and their causes helps operators quickly diagnose and resolve issues, minimizing downtime and preventing damage to the machine or workpiece. Below are some typical errors encountered on the M21 system:

1. Alarm 100: Tool Not Defined

This error occurs when the program calls for a tool that has not been properly set up or assigned in the tool library. Verify the tool number and ensure all tool offsets and parameters are correctly entered before restarting the program.

2. Alarm 150: Overtravel in X-axis

Triggered when the machine attempts to move beyond the allowed range on the X-axis, this alarm indicates either a programming error or mechanical limitation. Check the programmed coordinates, limit switch status, and machine setup to correct the issue.

3. Alarm 390: Spindle Not Responding

This alarm signals a failure in spindle activation, possibly due to wiring issues, motor faults, or incorrect M-code commands. Inspect the spindle system, verify control signals, and confirm proper use of spindle-related M-codes in the program.

Start your CNC machining project at VMT

With over 15 years of experience in CNC precision manufacturing, we deliver custom parts with the best look and the highest accuracy. With over 100 machines, including 4/5 axis centers and Fryer Machine CNC support, VMT can deliver parts within 24 hours. We are proficient in the Fryer M21 CNC Code Siemens Free workflow, ensuring best-in-class execution.

Frequently Asked Questions About Fryer M21 CNC Code

What is the Code M21 in CNC?

M21 is a machine-specific auxiliary function used in CNC programming. Its function varies depending on the machine’s configuration. In some systems, M21 might activate a specific clamp, enable a rotary table, or initiate a special cycle. Always refer to the machine’s manual or Siemens documentation (e.g., M21 CNC code Siemens) for the exact definition on a Fryer M21 or similar controller.

What is the T Code in CNC?

The T code in CNC specifies the tool number to be used. For example, T01 calls tool number 1. It is often followed by an M06 command, which instructs the machine to change to the specified tool. T codes are essential for multi-tool operations and precise machining processes.

What does M Mean in G-code?

In G-code, “M” stands for “Miscellaneous” function or command. M-codes control non-movement operations like turning on the spindle (M03), stopping it (M05), coolant on/off (M08/M09), and tool changes (M06). M-codes are essential for managing machine behaviors beyond simple positioning or cutting.

What is the M12 Code in CNC?

M12 is a miscellaneous command often used to engage or activate a specific machine function such as clamping. On some CNC machines, it may control hydraulic or pneumatic clamps, or automatic work-holding devices. Always consult the machine-specific manual, as M12 functions vary by manufacturer and controller type.