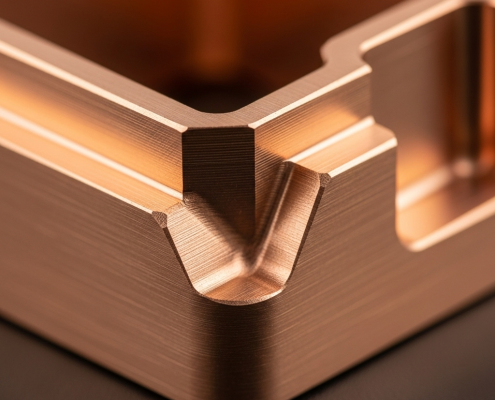

Copper CNC Machining

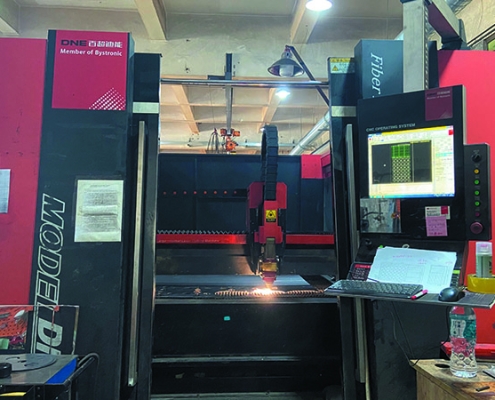

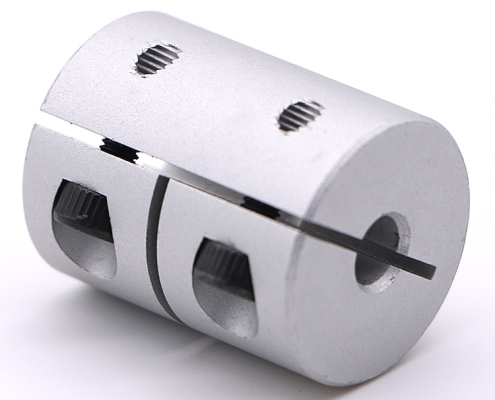

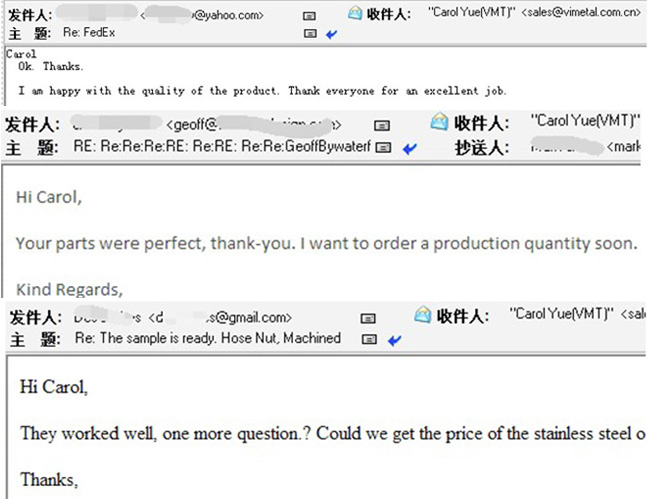

VMT specializes in delivering high-precision, high-quality copper CNC machining services tailored to your specific requirements.

We are certified with ISO 9001:2015 and IATF 16949 and hold 16 patents along with high-tech enterprise certificates. Whether you need prototypes, small batches, or large-scale production, our advanced machining capabilities and expertise ensure we meet your needs with precision and reliability.

- 2-hour Quotation

- ODM and OEM Services

- DFM Analysis

- Material Test Certificate