Advice on Compounding Extrusion

In the compounding extrusion process, encountering challenges can affect production efficiency and final product quality. Mastering the right techniques and insights significantly enhances results.

Compounding extrusion is a process that blends various polymers and additives to create customized materials. By following industry best practices, you can ensure better quality, efficiency, and consistency in your extruded products.

Let’s explore essential advice for mastering compounding extrusion techniques.

What is the Extrusion Phase?

The extrusion phase is where the compounded material is shaped and refined, making it critical for achieving final product specifications. During extrusion, melted materials pass through a die to form the desired shape. This phase requires precise control over temperature, pressure, and speed.

The barrel, screw, and die play vital roles in shaping the compound. The barrel’s temperature and screw speed affect the material’s flow and consistency, while the die dictates its final shape. Maintaining a stable flow of material reduces defects and irregularities, enhancing quality. Implementing compounding extrusion advice for plastics, like monitoring pressure and flow rates, can significantly improve efficiency and reduce product flaws.

The Process of Using a Compounding Extruder

Using a compounding extruder properly is essential for efficient production and achieving consistent results. Compounding extruders blend polymers and additives under controlled conditions. Factors like screw speed, temperature, and feed rate significantly affect product consistency.

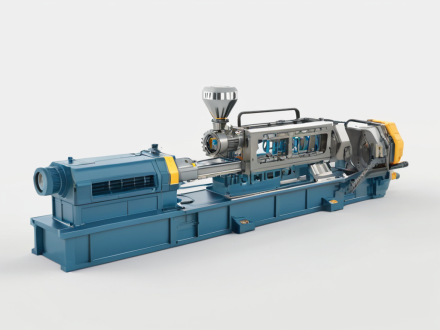

Twin-screw extruders are typically preferred for their ability to handle complex formulations and mix materials uniformly. Operators can adjust parameters such as screw rotation and heating levels based on the material type and desired outcome. Compounding extrusion advice for plastics emphasizes careful control of each setting to avoid poor dispersion, overheating, or other production issues, leading to a more consistent and high-quality end product.

What is the Process of Plastic Compounding by Extrusion?

The process of plastic compounding by extrusion involves several key steps that blend polymers with various additives to improve the material’s properties and adapt it for specific applications. Here’s an overview of the process:

1. Material Selection

Selecting the base polymers and additives, such as fillers, colorants, stabilizers, and plasticizers, is the initial and crucial step. These components are chosen based on the desired properties of the final product and specific application requirements. This selection phase ensures that the material will meet standards for strength, durability, flexibility, or color, depending on its intended use.

2. Feeding

The chosen raw materials are introduced into the extruder through a hopper. A loader system measures and delivers the exact quantities of polymers and additives into the extruder’s barrel. This precise feeding mechanism ensures consistency in composition, critical for maintaining uniform material properties throughout the compounding process.

3. Melting and Mixing

Heating Zones: The extruder is divided into multiple heating zones that progressively warm the material, melting the polymers and additives.

Screw Mechanism: A rotating screw within the extruder barrel facilitates thorough mixing as the materials melt. The screw’s design and speed ensure efficient blending and help break down the raw ingredients, resulting in a homogeneous mix.

4. Shearing and Homogenization

As the materials progress through the screw, high shear forces created by its rotation ensure a uniform blend. This step is essential for evenly distributing additives throughout the polymer base, leading to consistent properties such as color, texture, and performance in the final extrudate.

5. Extrusion

Once melted and uniformly mixed, the material is forced through a die, a tool that shapes it into the required form.

6. Cooling and Solidification

After shaping, the extrudate undergoes rapid cooling, typically by air or water, to solidify and stabilize its form. Effective cooling is critical for maintaining the product’s shape, preventing warping, and ensuring dimensional accuracy.

7. Cutting and Packaging

Cutting: Following cooling, the extruded material is cut into desired lengths, granules, or other shapes depending on its intended application.

Packaging: The final products are packaged for storage or shipment, completing the extrusion process. Proper packaging preserves the quality and integrity of the extrudates.

How to Choose the Right Equipment for Compounding Extrusion?

Selecting the appropriate equipment is crucial for the success of your compounding process. The right extrusion machinery not only guarantees consistent product quality but also minimizes downtime, enhancing overall efficiency in production.

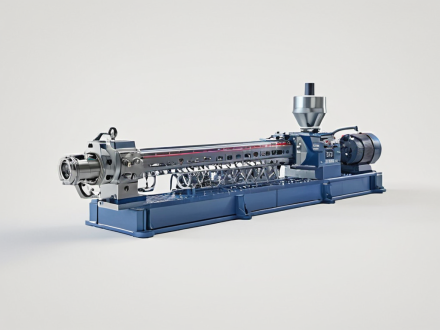

When choosing equipment, consider factors such as screw design, heating capacity, and throughput. Twin-screw extruders offer enhanced mixing capabilities for complex blends, while single-screw machines may suffice for simpler compounding needs. Laboratory-scale extruders are ideal for R&D and small-batch production, whereas industrial-scale extruders handle high volumes efficiently.

Optimizing Formulation in Compounding

Formulation is fundamental to the success of compounding extrusion, as it directly influences the final properties of the material. A well-designed formulation carefully balances polymers and additives to achieve specific characteristics essential for the intended application.

A good plastic compound formula includes polymers, stabilizers, fillers, and pigments in the right proportions to meet specific application requirements. Testing and adjusting formulations allows manufacturers to fine-tune properties like thermal resistance, durability, and appearance.

How to Enhance Efficiency in Compounding Extrusion Operations?

Improving efficiency in compounding extrusion is essential for reducing costs, minimizing waste, and maximizing production capacity. By optimizing key steps and employing best practices, manufacturers can achieve significant gains in both output and quality. Here’s advice for enhancing efficiency in compounding extrusion operations.

1. Streamline Material Preparation and Selection

Choosing the right materials and preparing them properly is a fundamental step toward efficient extrusion. Using high-quality, pre-screened polymers and additives minimizes contaminants and improves consistency in the final product. The selection of compatible additives also prevents machine issues such as clogging or excessive wear, helping to maintain smoother production with fewer stoppages. Efficient material preparation ensures the extrusion process runs seamlessly, increasing throughput and product quality.

2. Optimize Machine Settings and Parameters

Adjusting machine settings like screw speed, barrel temperature, and feed rate is essential to maintaining a stable production process. Fine-tuning these parameters can improve flow stability, reduce energy waste, and optimize product uniformity. Conducting regular tests to determine the best settings for specific materials prevents degradation and maintains consistency.

3. Use Automated Control and Monitoring Systems

Automation allows precise control of extrusion parameters, enhancing accuracy and reducing the potential for human error. With real-time monitoring, automated systems adjust temperature, speed, and feed rates based on the feedback received, which maintains optimal conditions for consistent output. This technology reduces manual intervention, improves process stability, and can lead to significant time and energy savings, enhancing overall production efficiency.

4. Focus on Efficient Material Feeding Techniques

Accurate and consistent material feeding is critical to avoid shortages or surges that can interrupt production. Using automated feeders such as gravimetric or loss-in-weight systems provides precise control over material dosage. These feeders automatically adjust rates to maintain target parameters, preventing fluctuations that could compromise quality.

5. Optimize Cooling and Solidification Phases

The cooling phase stabilizes the shape of extruded products, ensuring dimensional accuracy and preventing deformation. Proper cooling settings prevent warping and allow for faster solidification, which helps increase production speed without compromising quality. Implementing controlled cooling zones or automated cooling systems tailored to different material types ensures efficient cooling, supporting consistent product characteristics and quality.

What Are Common Challenges in Compounding Extrusion?

In compounding extrusion, various technical and operational challenges can impact production quality, efficiency, and consistency. Understanding and addressing these challenges helps manufacturers optimize the process and ensure a high-quality final product.

Compounding extrusion challenges often include issues like inconsistent material blending, melt fracture, and equipment wear. By identifying these obstacles and implementing best practices, manufacturers can improve efficiency and reduce waste.

How to Overcome the Key Challenges in Compounding Extrusion?

1. Inconsistent Material Blending

Inconsistent blending of polymers and additives is a common issue in compounding extrusion, leading to uneven material properties. This occurs when additives, such as fillers or stabilizers, are not uniformly distributed, affecting the final product’s strength and performance.

To address this, you can adjust the screw design and speed, which helps improve material mixing. By fine-tuning screw parameters and feed rate, consistency can be enhanced. Twin-screw extruders are especially effective in this regard, as they offer superior blending control, ensuring additives are evenly distributed throughout the polymer base for better product quality.

2. Melt Fracture and Surface Defects

Melt fracture occurs when the material flows unevenly through the die, causing rough or distorted surfaces that can affect the product’s appearance and performance. This typically happens when extruder speed is too high or die design is inadequate, leading to poor material flow. To minimize melt fracture, you can reduce the extruder speed, optimize die design, and adjust the extrusion temperature to ensure a stable melt flow.

3. Temperature Control Issues

Temperature fluctuations along the extruder barrel can cause material degradation or incomplete melting, negatively impacting product quality. Overheating can lead to polymer breakdown, while underheating may result in incomplete blending of additives.

To solve this, you should implement precise temperature controls using zoned heating to maintain optimal temperatures throughout the process. Regular calibration and maintenance of temperature sensors and controllers are crucial to minimizing temperature fluctuations and ensuring consistent material properties, thus reducing the risk of defects and degradation.

4. Equipment Wear and Maintenance

Continuous operation in compounding extrusion can lead to wear on essential extruder components like screws, barrels, and dies, decreasing efficiency and leading to inconsistent product quality. To prevent such issues, manufacturers should establish a preventive maintenance schedule to inspect and replace parts before significant wear occurs. Predictive maintenance technologies can also help identify early signs of wear, enabling proactive repairs and reducing unplanned downtime. Regular maintenance ensures that equipment operates efficiently, minimizes downtime, and maintains product quality, which is crucial for continuous production.

5. Inconsistent Color Matching

Inconsistent color matching often occurs when pigments or dyes are not uniformly mixed, leading to color variations that can be problematic, particularly for products where appearance is critical. To achieve consistent color, manufacturers can use pre-mixed color masterbatches to ensure even distribution of pigments. Additionally, fine-tuning the compounding formulation and conducting small-scale tests before full-scale production can help verify color consistency. Adjusting extrusion parameters such as screw speed, temperature, and feed rate further ensures that pigments are well incorporated, leading to consistent color in the final product.

In Conclusion

By prioritizing consistent quality, optimized mixing, efficient equipment use, temperature control, and material compatibility in composite extrusion, manufacturers can achieve reliable production results that meet their specific industry requirements. This holistic approach not only enhances the performance of the extruded composites but also contributes to overall efficiency and effectiveness in the manufacturing process.

Start Your Extruding and CNC Machining Project

Are you in the process of selecting a manufacturer for extrusion and CNC machining services? Choosing VMT would be an excellent option, as we provide seamless one-stop precision manufacturing services that cover everything from design to the final product. We offer aluminum profiles of various lengths and intricate geometric shapes, catering to your product development needs. Our combination of extruded aluminum profiles with diverse manufacturing services not only grants you unparalleled design flexibility but also helps minimize production costs.

Frequently Asked Questions

What is the Process of Extrusion Compounding?

Extrusion compounding is a process where raw materials, typically plastics or polymers, are mixed with additives like colorants, stabilizers, or fillers. The material is fed into an extruder, where it is heated and melted. The screw inside the extruder ensures uniform mixing while pushing the material through a die to form a continuous shape, such as pellets, sheets, or profiles. This method combines both the extrusion of a base material and the compounding of various additives to achieve the desired properties of the final product. It’s commonly used in manufacturing plastics for various industries.

How to Improve Extrusion Process?

To improve the extrusion process, it’s crucial to focus on optimizing parameters like temperature, pressure, and screw speed. Ensuring that the raw material is of consistent quality is also essential. Fine-tuning the extrusion speed and adjusting the cooling system can enhance product quality and consistency. Regular maintenance of the extruder, including cleaning and checking the wear on the screws, barrels, and dies, can help maintain efficiency. Additionally, using the right additives and ensuring proper mixing during compounding can result in improved performance and reduced defects in the final product.

What is the Difference Between Extrusion and Compounding?

Extrusion and compounding are both critical processes in material manufacturing, but they serve different purposes. Extrusion is the process of shaping material, typically plastics, by forcing it through a die, creating continuous forms like sheets, pipes, or profiles. Compounding, on the other hand, involves mixing polymers with various additives such as fillers, stabilizers, or colorants to enhance the material’s properties before it is shaped. While extrusion shapes the material, compounding focuses on improving its performance or characteristics. In many cases, these two processes are combined to produce high-quality materials for specific applications.