VMT’s blogs aim to share our practical experience and knowledge accumulated during the manufacturing and product development process. Our goal is to use these articles to help you improve product design and increase your understanding of CNC machining, 3D printing, rapid prototyping, low-volume manufacturing, and surface treatment technologies. The information we provide is designed to provide actionable guidance and insights for your CNC machining projects.

Cold Forging vs Hot Forging: Everything You Need to Know

Forging is a metal forming process that deforms metal by applying compressive force. Depending on the temperature, it is divided into hot forging, warm forging and cold forging. Hot forging is performed at a high temperature to improve the plasticity and forming ability of the material; cold forging is performed at a lower temperature to pursue high precision and surface quality. Both have their advantages and challenges. This article will explore the differences between cold forging and hot forging.

What is Forging?

Forging is a machining method that uses forging machinery to apply pressure to metal blanks to make them plastically deform to obtain forgings with certain mechanical properties, shapes and sizes. It is one of the important processes in metal machining and is widely used in various fields such as aerospace, power equipment and shipbuilding.

What is Cold Forging?

Cold forging, as a forming process performed below the recrystallization temperature of metal materials, is a key branch in the forging field. It applies great pressure to metal materials to cause them to undergo plastic deformation to change their shape and size. Cold forging is performed at a temperature close to or slightly above room temperature without the need for heating treatment, thereby maintaining the fine grain size and original mechanical properties of the material while reducing oxidation and decarburization.

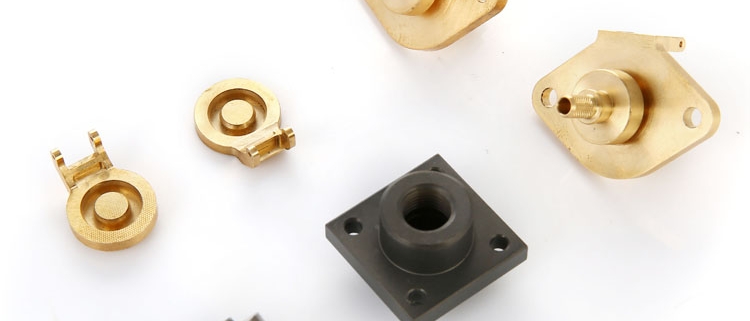

This process is suitable for metals and their alloys with low deformation resistance and good plasticity, such as aluminum, copper, low-carbon steel, etc., and can produce high-precision, high-quality products. Cold forging is widely used in the automotive, aerospace, electronics and other fields, especially in the manufacture of automotive parts such as piston pins and tire nuts.

What is Hot Forging?

Hot forging is a metal machining process performed above the recrystallization temperature of metal materials. It heats the metal material to a high temperature and uses a hammer or press to apply compression force to cause it to undergo plastic deformation to form the desired shape and size.

This process can significantly improve the plasticity and fluidity of the metal, reduce deformation resistance, and make it possible to forge complex shapes and large-sized parts. At the same time, hot forging can also improve the internal structure of the metal, improve the mechanical properties of the material and production efficiency.

The Difference Between Cold Forging and Hot Forging.

The main differences between cold forging and hot forging lie in temperature conditions, material properties and deformation effects. Cold forging is carried out at room temperature or slightly above room temperature, pursuing high precision and surface quality, which can improve material strength and hardness, but has high deformation resistance and requires high-precision molds and high pressure.

Hot forging is carried out above the metal recrystallization temperature, which uses high temperatures to increase the plasticity and fluidity of the material and reduce deformation resistance. It is suitable for manufacturing complex shapes and large-sized parts, but may be accompanied by warping and relatively low tolerance accuracy, and requires subsequent processing to optimize performance. These differences make the two have different focuses in terms of application areas, process characteristics, cost and environmental impact.

Which Metals can be Cold Forged?

Aluminum and aluminum alloys: Pure aluminum and some aluminum alloys, are often used for cold forging due to their good plasticity and deformation ability.

Copper and copper alloys: including brass, bronze and other copper alloys. These materials can maintain good plasticity and deformation ability during the cold forging process, thereby obtaining the required shape and mechanical properties.

Low carbon steel and medium carbon steel: These steels have good plasticity and toughness at room temperature and are suitable for cold forging. Through cold forging, the strength and hardness of parts can be significantly improved.

Low alloy structural steel: Some low alloy structural steels also have good cold forging properties and can be plastically deformed without heating.

Other Metals: In addition to the main metals mentioned above, there are some other metals and alloys that can also be processed by cold forgings, such as titanium, titanium alloys, nickel and nickel-copper alloys.

Advantages and Disadvantages of Cold Forging and Hot Forging.

Advantages of Cold Forging.

Improve material properties: During the cold forging process, the metal grains will be refined, thereby increasing the strength and hardness of the metal. This strengthening effect makes the cold forged parts show higher fatigue and fracture resistance when subjected to load.

High precision: Since cold forging is carried out at room temperature or slightly higher temperature, the material has a greater resistance to deformation, so precise die design and greater mechanical pressure are required. This process feature enables cold forgings to have higher dimensional accuracy and surface quality.

High production efficiency: The cold forging process is relatively simple and has high production efficiency, and can quickly produce a large number of high-quality parts.

Disadvantages of Cold Forging.

High equipment requirements: Cold forging requires high-precision, high-rigidity equipment and molds to ensure the dimensional accuracy and surface quality of the product. This increases the investment cost of the equipment and the difficulty of maintenance.

Limited material applicability: Not all metals are suitable for cold forging. Some materials with poor plasticity or high deformation resistance are prone to cracking or uneven deformation during cold forging.

Advantages of Hot Forging.

Improve material plasticity: The plasticity and fluidity of metals are significantly improved at high temperatures, reducing deformation resistance and making forging of complex shapes and large-sized parts possible.

Improve material structure: Hot forging can improve the internal structure of metal, eliminate casting defects and improve the mechanical properties of materials.

Reduce stress concentration: During the hot forging process, the metal undergoes plastic deformation, which can release and reduce the stress concentration inside the material and increase the service life of the parts.

Disadvantages of Hot Forging.

Low tolerance accuracy: Due to problems such as thermal expansion and contraction and uneven deformation of materials during the hot forging process, the tolerance accuracy of the product may be relatively low.

High energy consumption: Hot forging requires heating the material to a high temperature, so the energy consumption is relatively high. At the same time, the heating process may also produce harmful gases and waste slag and other environmental pollution problems.

Complex process: The hot forging process is relatively complex and requires strict control of process parameters such as heating temperature, forging temperature and forging speed to ensure product quality and performance.

In Conclusion

The main difference between cold forging and hot forging lies in the operating temperature and changes in material properties. Cold forging is performed at room temperature and improves metal strength through strain hardening, while hot forging is performed at high temperatures to avoid strain hardening, resulting in better ductility and lower hardness.

VMT provides comprehensive cold and hot forging services, including die design and manufacturing, forging, machining, polishing and electroplating. We have advanced testing equipment and rigorous quality control procedures to ensure that the quality of raw materials and final products meets your requirements.

Frequently Asked Questions About Cold Forging and Hot Forging

Is Cold Forging Better than Hot Forging?

Cold forging and hot forging each have their own advantages and disadvantages, and it is not possible to simply judge which one is stronger. Cold forging is carried out at room temperature, which can significantly improve the strength of the metal and ensure high precision and high surface quality, but it requires higher material and mold quality, as well as greater mechanical pressure. Hot forging is operated in a high temperature environment, which is conducive to the forging of complex shapes and large-sized parts, improving the internal structure of the material, and improving toughness and plasticity, but may be accompanied by lower tolerance accuracy and higher energy consumption costs. The choice of which process should be considered comprehensively based on factors such as specific application scenarios, material properties, product requirements and production costs.

Is Cold Forging Expensive?

The cost of cold forging is affected by many factors, including material cost, mold cost, equipment investment, production efficiency, and subsequent machining procedures. Although cold forging has high requirements for equipment accuracy and mold design, its high production efficiency and good material utilization may reduce the overall cost to a certain extent. However, the specific cost still needs to be evaluated according to the specific situation.

Which Metals Cannot Be Cold Forged?

High-hardness metals: such as certain high-carbon steels and alloy steels, have high hardness and deformation resistance at room temperature and are difficult to process by cold forging.

Brittle Materials: Some metals exhibit brittleness at room temperature and are prone to fracture or crack propagation, making them unsuitable for cold forging.

Low plasticity materials: Metals with poor plasticity are prone to uneven deformation or cracking during the cold forging process.