When searching for a reliable partner in medical-grade precision manufacturing, the customer chose VMT, a CNC machining factory with 15 years of experience. What convinced them was not only our advanced equipment but also our willingness to fully understand their real needs instead of simply processing CAD drawings. We took time to learn how the laparoscopic tool would be used in surgery, how its parts work together, the strict sterilization requirements, and the importance of smooth and safe surfaces for patient safety.

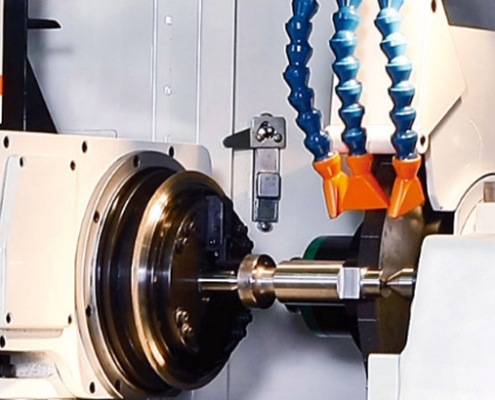

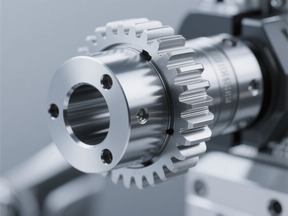

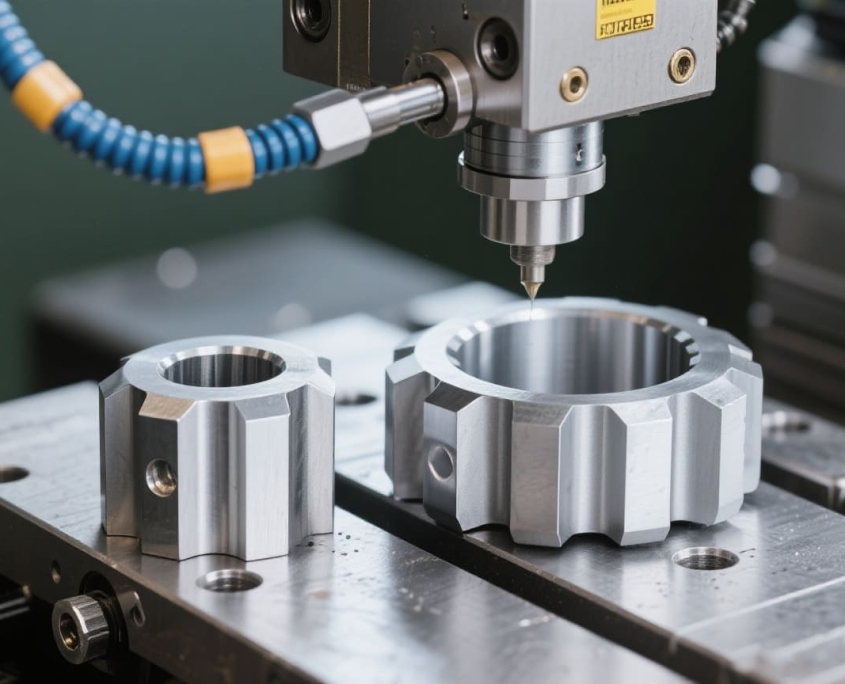

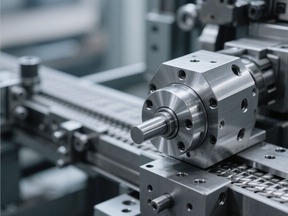

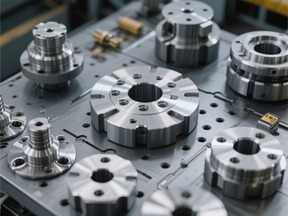

To meet these needs, we designed a complete one-stop solution. We used high-precision CNC machining with an accuracy of 0.005 millimeters to make parts from 316L medical-grade stainless steel. This material was selected for its strength, resistance to corrosion, and safety in medical use. We applied a multi-step deburring process to remove even the tiniest burrs, including those in hidden internal channels, and finished the parts with electropolishing and passivation. This created a consistently smooth surface, improved corrosion resistance, and ensured the parts met strict sterilization and safety standards.

Beyond manufacturing, we also provided full documentation including material certificates, process records, and quality inspection reports. These documents were essential for medical compliance and traceability. By offering this end-to-end support, we did more than deliver precision parts. We helped simplify their supply chain and reduce the burden of regulatory and quality control challenges.