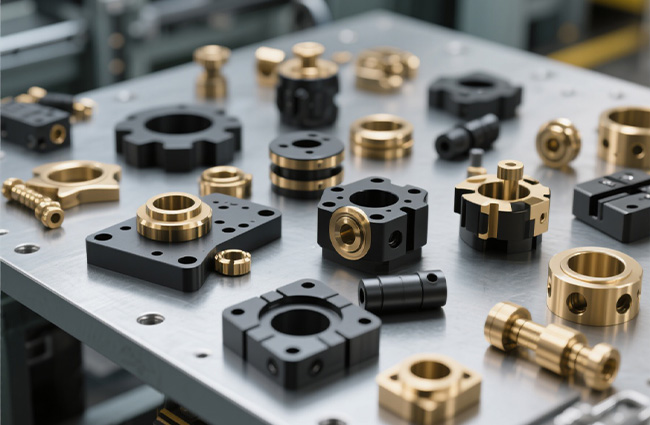

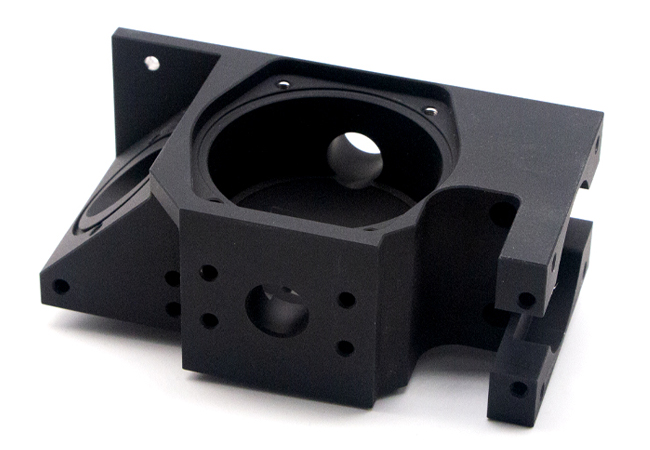

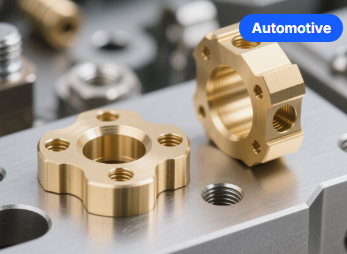

Urgently seeking a more sustainable and cost-effective solution, the client expanded their supplier search globally. After a rigorous review process, including qualification certification, project experience assessment, and quality control verification, they ultimately selected VMT. From their first meeting, they realized that VMT was more than just a supplier; rather, it was a CNC precision machining shop renowned for its high quality and reliable service, offering a true one-stop solution.

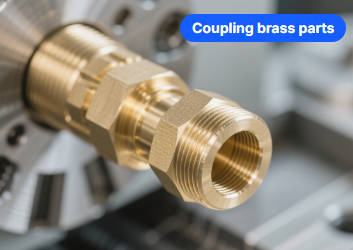

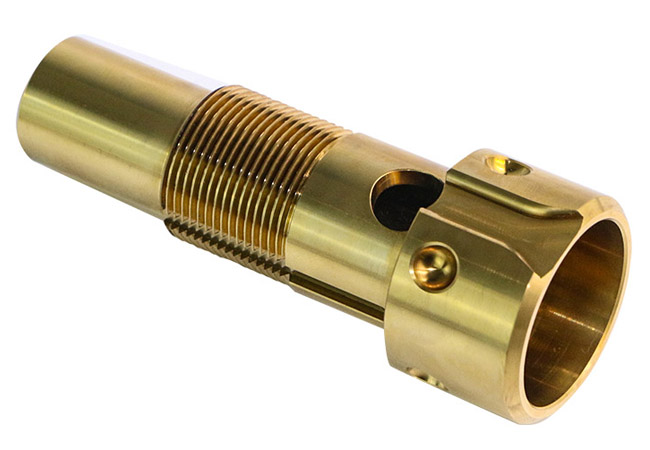

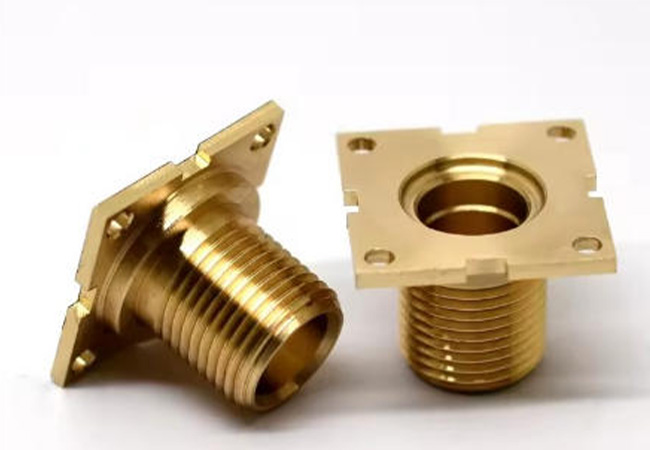

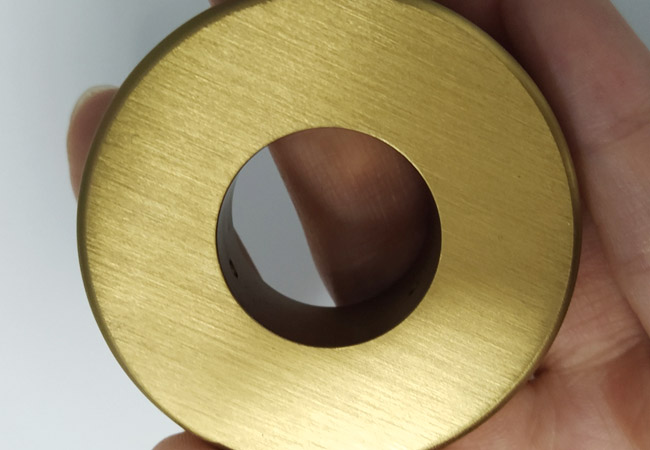

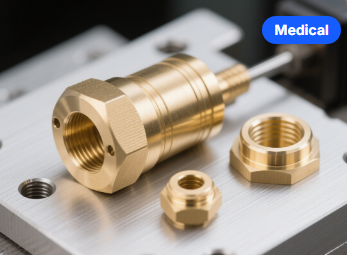

We not only carefully interpreted the client’s technical drawings but also thoroughly understood the role of these parts in pressure-sealed marine sensors, meticulously identifying key requirements such as thread machining, tolerance control, and surface finish.

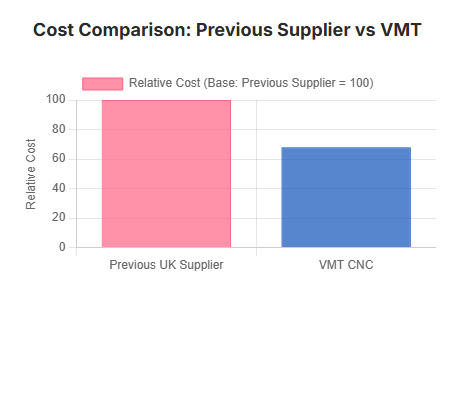

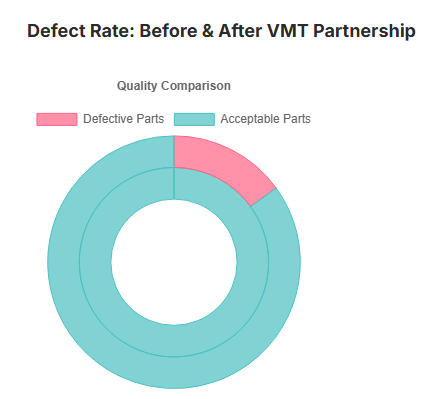

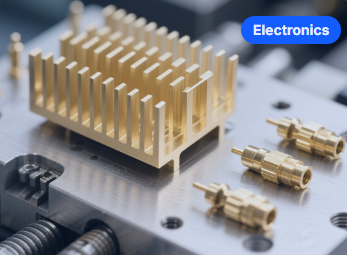

As a CNC machining precision parts manufacturer with over 15 years of experience, VMT boasts 0.005mm machining accuracy and advanced production equipment, fully capable of meeting the client’s CNC brass connector parts needs. Our proposed solution offered a highly competitive cost, backed by stringent quality assurance, including pre-shipment inspection and material certification, and a delivery schedule that aligned closely with the client’s time to market.