4. Electropolish

This electrochemical process removes a thin layer of the metal surface, reducing roughness and enhancing brightness. It also improves corrosion resistance and is particularly beneficial for complex or small components that are difficult to polish mechanically.

5. Alodine Finish

Also referred to as chromate conversion coating, this chemical treatment enhances corrosion resistance and improves paint or adhesive bonding. It is widely used in the aerospace and electronics sectors for brass and other non-ferrous metals.

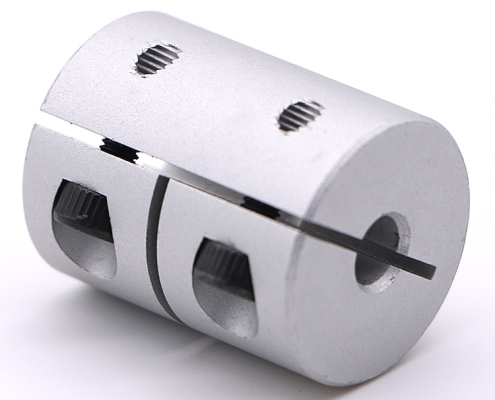

6. Electroless Nickel Plating

A chemical plating technique that coats brass with a uniform layer of nickel, enhancing hardness, corrosion resistance, and wear properties. Unlike traditional electroplating, it doesn’t require electricity, making it ideal for parts with complex geometries.

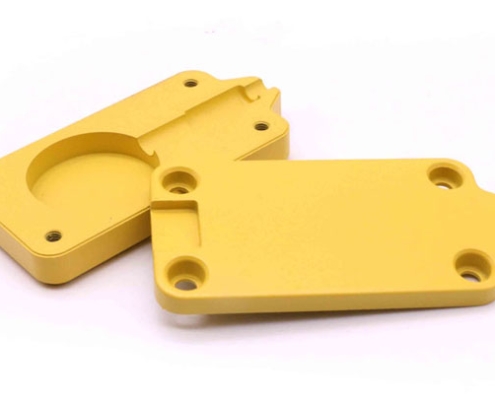

7. Painting

A versatile finishing method that adds color, UV protection, and surface sealing. Various paint types can be applied depending on the part’s environment and purpose, ranging from decorative to functional coatings.

8. Powder Coating

A durable, protective finish where powder is electrostatically applied and then cured under heat. It offers excellent abrasion and weather resistance and is available in a wide variety of colors, sheens, and textures.

9. Electrophoresis

This method uses an electric field to deposit a uniform, corrosion-resistant film over brass parts. It is ideal for coating intricate shapes and internal surfaces and can be used in combination with powder coating or paint for enhanced durability.

10. Brushed Finish

A linear pattern is created on the surface using brushes or abrasive belts. The resulting texture gives a clean, satin appearance. It’s commonly found in high-end electronics, appliances, and decorative parts due to its modern and premium look.