Five-axis machining is an advanced CNC machining technology that can simultaneously control the five axes of a machine tool to produce complex parts. The price of five-axis CNC machining services depends on the equipment, part complexity, material, and precision. The average price ranges from $75 to $250 per hour.

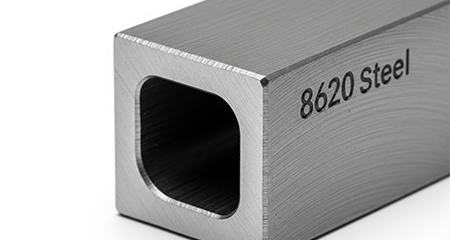

8620 steel offers a strong balance of machinability, toughness, and surface hardenability. It’s ideal for parts like gears and shafts that require wear resistance and durability, making it a reliable choice across automotive, industrial, and aerospace applications.

6061 aluminum stands out as a versatile and high-performance material, ideal for CNC machining due to its excellent mechanical strength, corrosion resistance, and adaptability across industries. At VMT, we specialize in precision CNC machining of 6061 aluminum T6 parts, delivering components that meet tight tolerances and demanding specifications.

PLA is perfect for projects that prioritize ease of use, a glossy finish, and eco-friendliness, making it ideal for prototypes, toys, and decorative models. ABS, however, is better for demanding applications requiring strength, durability, and heat resistance, such as functional parts or professional use. Choose PLA for simplicity and sustainability, and ABS for toughness and advanced performance.

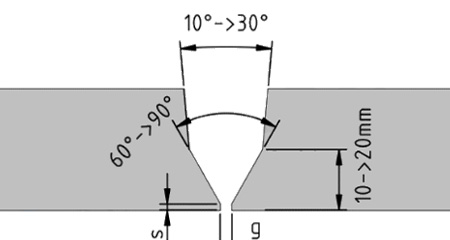

Beveling is a crucial CNC machining technique that enhances a part’s functionality, fit, and appearance. By mastering bevel design and application, manufacturers can ensure higher-quality products with improved performance and durability across various industries.

Understanding the balance between stiffness and strength is essential for designing CNC-machined parts that are both safe and efficient. Stiffness ensures parts maintain their shape under load, while strength prevents failure under stress.

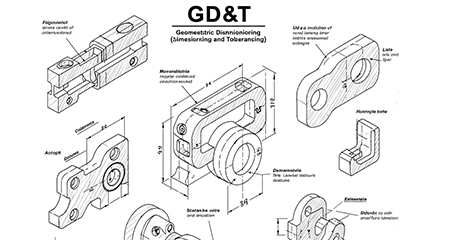

GD&T transforms good parts into great ones by aligning design intent with manufacturing capability. At VMT, we’ve mastered applying GD&T across our classification of grinding machine portfolio to deliver unmatched precision and reliability.

Understanding the types of pins is crucial for precision and efficiency in engineering. From fasteners pins, lock pins to different pin types, each plays a unique role. Partner with VMT for custom solutions that guarantee exceptional quality.

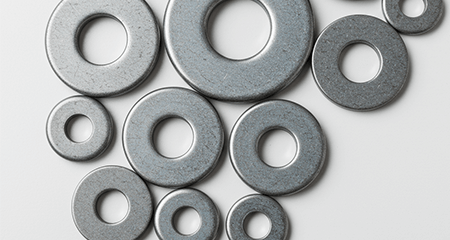

The 10 common types of washers include flat washers, torque washers, flat washers, fender washers, countersunk washers, shoulder washers, tapered washers, C-type washers, lock washers and spring washers. They are used for different application scenarios such as load distribution, anti-rotation, stress diffusion, electrical insulation, shock absorption and anti-loosening.

When comparing TPR vs. TPE, both materials offer valuable benefits and are widely used across industrial and consumer products. TPR is a cost-effective choice for applications needing softness and basic durability, while TPE excels in demanding environments requiring high flexibility, chemical resistance, and long-term performance.