Renowned for its exceptional strength-to-weight ratio and corrosion resistance, 6061 aluminum alloy is a cornerstone of many industries. However, understanding its specific…

Electrolytic coloring is an electrochemical process that modifies the surface of metals by depositing ions within an anodized oxide layer. This results in durable colors that…

Bearings types include ball, roller, plain, fluid, and magnetic bearings. Each type of bearing has its own working principle, bearing components, performance…

303 Stainless Steel Material

BLOG

What is 303 Stainless Steel?

303 stainless steel is an austenitic stainless steel alloy specifically designed for improved machinability. It contains chromium and nickel like 304 stainless steel …

VMT is a top CNC turning manufacturer, provides rapid turnaround with quotes in two hours, DFM feedback within 24 hours, and delivery as fast as one day. The company…

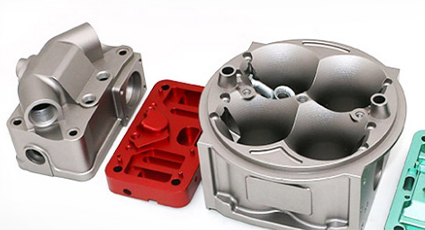

We offer high-quality CNC machining, die-casting, sheet metal fabrication, and 3D printing services, catering to a wide range of auto part needs, from prototyping to…

High-Speed Machining is a advanced manufacturing process characterized by exceptionally high spindle…

Aluminum coatings provide corrosion resistance, durability, and visual enhancement for a wide range of industries. From automotive to medical, the correct …

4-axis cnc machining involves adding a rotating axis, often called the A-axis, to the three traditional cnc axes. This …

A sheet metal prototype is a physical representation of a product made from sheet metal to test form, fit, and function before full-scale production. Unlike plastic…

.jpg)