Inconel and Titanium are both popular choices in CNC machining, but they are quite different…

Fillet machining definition refers to the process of creating rounded transitions between two intersecting surfaces in…

Soft machining in CNC manufacturing involves the precision machining of low-hardness materials such as…

Aluminum offers a lightweight, corrosion-resistant, and easy to machining solution for many CNC projects…

Taper turning is a machining process used to create a conical surface on a workpiece, where the diameter changes uniformly along its length. It is fundamental…

CNC machining aluminum is a subtractive manufacturing process that utilizes computer numerical control to precisely shape aluminum alloys into…

Boring machining is a machining process that improves the accuracy and surface quality of an existing hole. Unlike drilling, which simply removes material to create…

Knurling is a common machining process, typically performed on CNC lathes. It involves using a specialized knurling tool to create a regular pattern, such as…

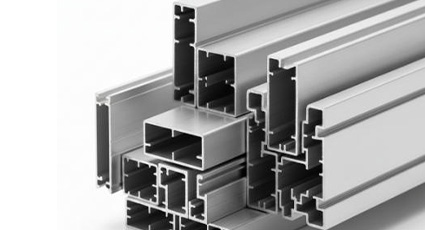

Aluminium extrusion is a fundamental manufacturing process that transforms aluminum alloy into objects with a definitive cross-sectional profile. VMT, an experienced…

When choosing between copper and aluminum for manufacturing, key differences lie in their properties. Copper offers superior electrical and thermal…