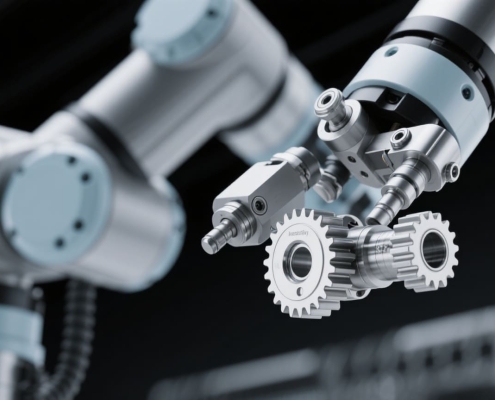

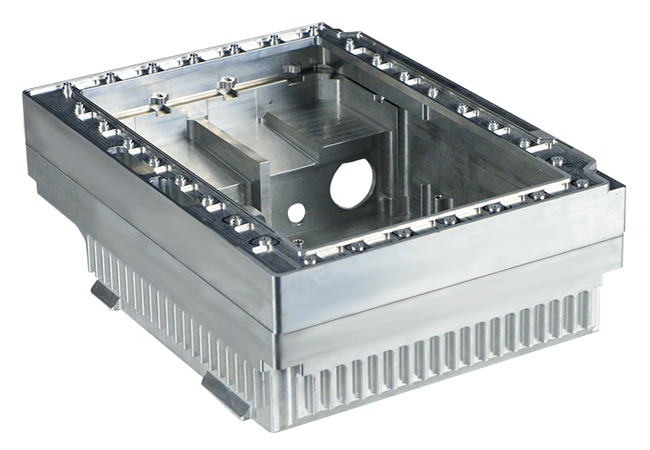

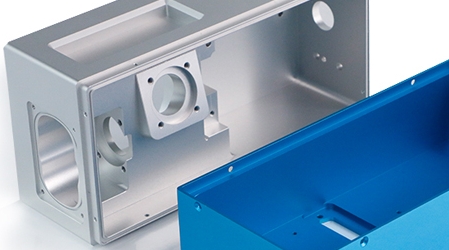

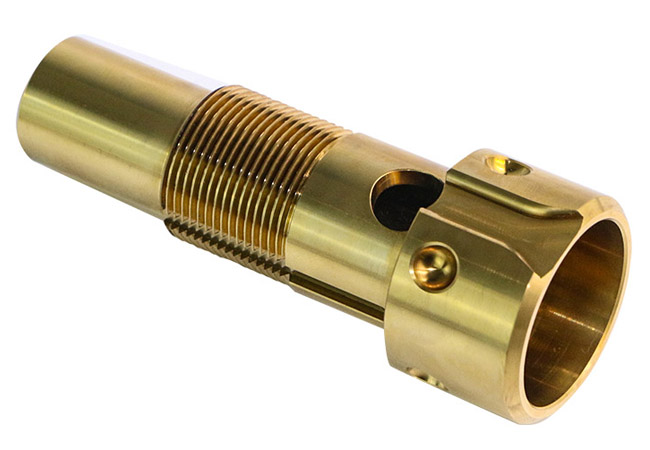

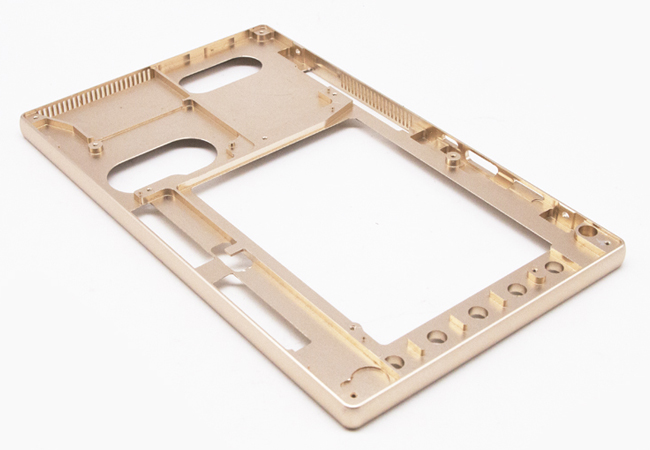

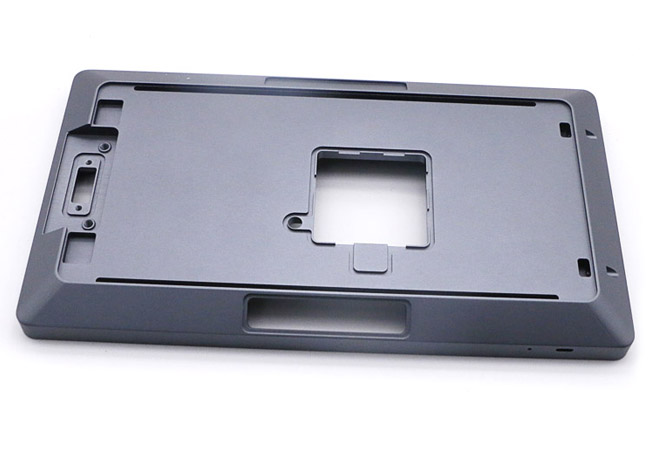

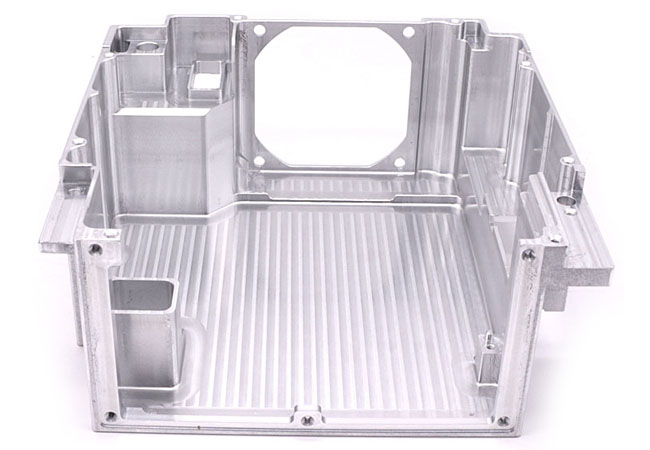

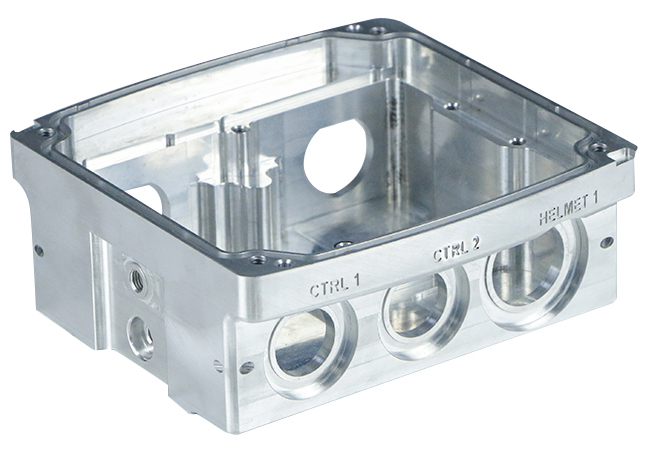

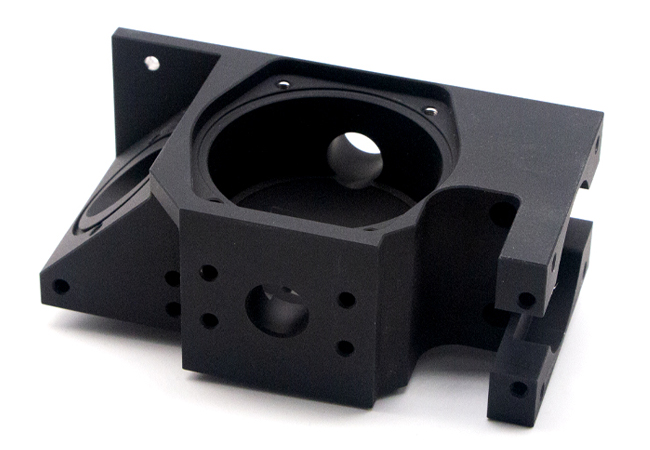

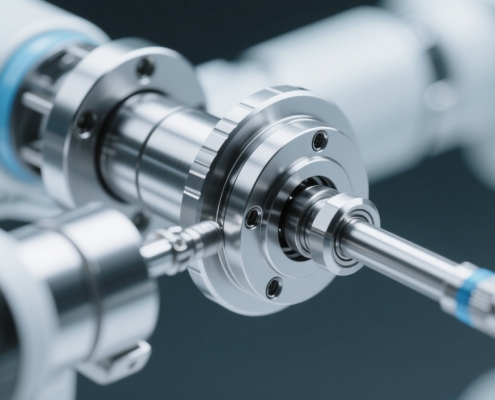

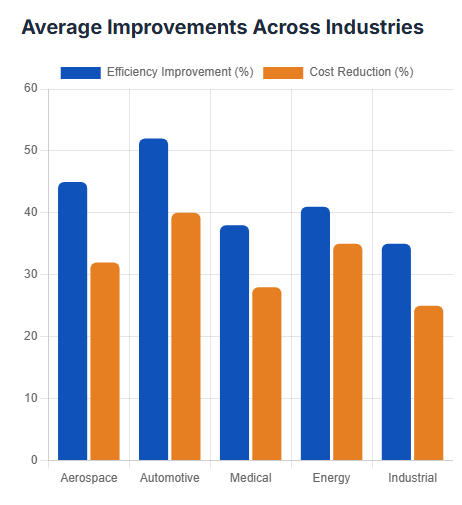

Our CNC machining solutions consistently improve key manufacturing metrics across multiple industries. Using precision CNC milling and turning, 5-axis machining, and tight tolerance machining, we ensure every part meets exact specifications while minimizing material waste. Advanced CNC prototyping and custom machining services speed up product development, and professional surface finishing enhances both durability and appearance. These capabilities boost production efficiency, reduce scrap rates, and improve quality and operational performance at every stage.

We also use a data-driven approach to monitor CNC process stability, material usage, and production throughput in real time. By combining advanced CNC inspection tools with optimized tool path programming, we increase yield and minimize downtime. With multi-supply chain integration and strict process control, our yield rate reaches 98%. With over 15 years of experience producing high-quality custom components, we offer multi-process coordination, various material combinations, and more than 40 custom surface finishing options to meet diverse client needs.