Brushing Surface Finish: Complete Guide

The metal brushing surface treatment process creates a fine and uniform texture on the metal surface through mechanical or chemical methods, which not only enhances the tactile feel of the material, but also adds a unique visual effect to it. Are you interested in brush surface preparation tools, techniques and practical methods? This guide will provide you with comprehensive and in-depth information.

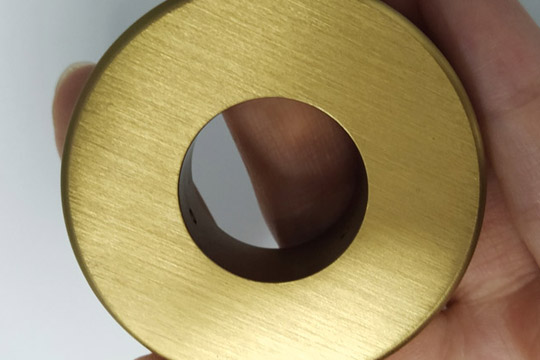

What is the Brushed Metal Surface Finishing Process?

Brushed metal surface treatment is a method of using mechanical tools to produce fine textures or lines on the metal surface. This process not only brings a unique visual effect to metal products, but also improves the durability and functionality of its surface, improving the overall quality of the product.

Detailed Explanation of Brush Finishing Process.

The brush finishing process generally includes the following steps:

Surface Preparation:

Before applying a topcoat, the surface needs to be carefully prepared, including removing dust, oil and rust, repairing cracks and holes in the substrate, and sanding and polishing as appropriate to improve paint adhesion, especially for materials such as brushed metal, brushed steel and brushed aluminum.

Apply Primer:

The main function of primer is to enhance the adhesion between the coating and the substrate and to improve the weather resistance, corrosion resistance and other properties of the coating.

According to the type of paint and the characteristics of the substrate, choose a suitable primer for painting.

Apply Topcoat:

According to the design requirements, select the appropriate topcoat for painting. The number of times the topcoat is painted depends on the performance of the paint and the decoration requirements. Generally, 2-3 times are required. During the painting process, pay attention to the uniformity, glossiness and thickness of the paint to avoid defects such as sagging, bubbling and missing paint.

Later Steps:

After brushing, the coating is trimmed to remove excess paint and imperfections.

According to the drying time and curing conditions of the coating, carry out necessary maintenance to ensure that the coating achieves optimal performance.

Advantages of Brushed Finishes.

Brushed finishes are widely used because they are easy to apply, flexible in use, and produce a clean, attractive look. They work well on many surfaces and are suitable for both practical and decorative purposes. The following shows the main advantages of brushed finishes.

| Advantage | Detailed Description |

|---|---|

| Strong Construction Flexibility | Brushing can be done in almost any environment. It easily covers corners, edges, and narrow areas that other tools may miss. |

| Significant Cost-Effectiveness | Brushing helps control the amount of paint used, reducing waste and saving costs. It works especially well for small or detailed areas. |

| Good Decorative Effect | Brushing creates a smooth and even surface. The coating thickness and gloss can be adjusted to get different looks, from matte to shiny. |

| Enhanced Adhesion and Durability | The brush helps paint stick better to the surface, making the coating stronger and less likely to peel or crack. |

| Ease of Operation and Maintenance | Brushing is simple to learn and needs little equipment. It’s easy to repair or touch up painted areas when needed. |

| Environmental and Safety Benefits | Brushing produces less paint mist and fewer fumes, making it safer for workers and better for the environment. |

What Materials Can Be Brushed?

Brush coating technology has shown a wide range of application potential in metal surface treatment, especially suitable for a variety of metal materials such as stainless steel, aluminum alloy, and iron. These metal surfaces are often imperfect due to scratches, oxidation, or natural wear during the manufacturing process, and the brush coating process can effectively solve these problems.

Stainless steel: Brushing can not only cover minor flaws on its surface, but also give it a richer color selection by choosing the right paint, from classic silver to deep black, and even bright colors, which can be easily achieved, greatly improving the visual effect and decorativeness of stainless steel products.

Aluminum alloy: By brushing, a protective film can be formed on the surface of aluminum alloy, which effectively prevents oxidation and corrosion and prolongs its service life. At the same time, brushing can also add a unique gloss and texture to the aluminum alloy.

Iron and Carbon Steel: Brushing iron or carbon steel surfaces can help remove rust and improve adhesion before painting or coating. It also creates a uniform finish that enhances the overall appearance and increases resistance to wear and environmental factors.

Copper and Brass: Brushing these materials brings out a clean, matte texture and eliminates surface tarnish or oxidation. In decorative applications, this can give copper and brass a sophisticated aged or modern industrial look, depending on the brush pattern used.

Zinc and Zinc-Alloy: Zinc materials, often used in die-casting, benefit from brushing to improve coating adherence and remove minor casting defects. This enhances the surface quality, especially before plating or painting processes.

Titanium: Although titanium is naturally corrosion-resistant, brushing can be used to create a sleek, satin finish for aesthetic applications in aerospace, medical, or consumer products. The brushed finish also reduces light reflection and enhances grip.

How to Brush Metal Surfaces?

1. Pre-Brush Stage

Clean the metal surface with an industrial degreaser to remove grease and dirt. Check for and repair any scratches or dents. Keep the metal temperature between 15°C and 25°C.

2. Brushing Stage

Apply steady pressure and brush in a fixed direction to create a matte brushed effect on metal surfaces. When brushing stainless steel, hold the brush at a 45-degree angle to the grain. Control the brush speed between 1,500 and 2,000 RPM and adjust the brushing time according to the effect.

3. After Brushing

After brushing, clean the metal surface with a non-abrasive solvent to remove any residue. Check for texture consistency. Passivate if necessary. Perform a visual inspection and surface roughness test to ensure quality.

Factors Affecting Brushing Finishing Quality.

There are many factors that affect the quality of brush finishing. These factors run through all aspects of the brushing process, from material selection, surface treatment to construction operations, and will have an important impact on the final brushing effect. The following are some of the main influencing factors:

| Category | Influencing Factor | Description |

|---|---|---|

| 1. Material Factors | Paint Quality | The type and quality of paint determine adhesion, wear resistance, weather durability, and decorative effect. High-quality paints result in smoother, more uniform finishes. |

| Diluent Selection | The type and amount of diluent affect paint viscosity and flow. Incorrect ratios can cause poor leveling, excessive thickness, or dripping. | |

| 2. Surface Treatment Factors | Cleanliness | Surface must be free of oil, rust, old coatings, or dust. Contaminants reduce paint adhesion and cause defects. |

| Surface Roughness | Proper roughness improves adhesion. Overly smooth or overly rough surfaces can negatively affect bonding and visual quality. | |

| 3. Construction Operation Factors | Construction Technique | The skill of the operator is crucial. Proper brushing methods ensure uniform coating, free of brush marks, runs, or bubbles. |

| Construction Tools | Selecting the right brush, roller, or spray gun (material, type, size) for the specific paint and surface improves finish consistency. | |

| 4. Other Factors | Paint Mixing Ratio | Accurate mixing ratios are essential. Incorrect ratios can affect drying, curing, or long-term durability. |

| Drying Time | Sufficient drying between coats prevents blistering, peeling, or cracking. Rushing the process often leads to coating failure. |

Comparison of The Finish to Other Metal Finishes.

When choosing the most appropriate metal surface treatment for a project, it is important to understand the characteristics of various processes and their impact on the success of the metal machining project. The following is a comparative analysis of wire drawing surface treatment and several common metal surface treatment methods:

1. Brushed vs Mirrored Finishes

Visual Effect: The brushed surface gives the metal a fine, directional, satin-like texture, while the mirrored surface is highly reflective, emphasizing its smoothness and glossiness.

Surface roughness: The average roughness of the brushed surface is 0.2 to 1.0 microns, which makes it less susceptible to scratches and fingerprints than a mirror surface.

2. Comparison Between Brushing and Polishing

Smoothness and reflectivity: Polishing produces a smoother and more reflective surface than brushing, with Ra values as low as 0.01 microns. However, brushing has advantages in cost-effectiveness and processing time.

Suitability: Polishing provides the ultimate in gloss, but brushing is more desirable in many applications due to its economy and efficiency.

3. The Difference Between Brushing and Sandblasting

Surface texture: Sandblasting creates a matte surface through high-pressure sand impact, with a higher Ra value (1.6 to 3.2 microns), giving the metal stronger anti-slip and anti-fingerprint properties. Brushing focuses on delicate linear textures and is more aesthetically pleasing.

Corrosion resistance and strength: Shot blasting increases the corrosion resistance of metals but may reduce their fatigue strength. In contrast, wire drawing has less effect on strength.

4. Comparison Between Brushing and Anodizing

Anodizing is an electrochemical process that forms a protective oxide layer on the metal surface, significantly increasing its hardness, while brushing is a mechanical process that physically creates a specific texture on the metal surface.

Start your Brushing Surface Finish project at VMT!

VMT offers a wide range of surface finishing services, including anodizing, sandblasting, polishing, plating, powder coating, painting, PVD, engraving, and brushing.

We also have strong CNC machining capabilities for precise milling and turning of metals and plastics. Our advanced machines ensure high accuracy, smooth surfaces, and stable quality for both samples and large production runs.

If needed, we can suggest the best combination of CNC machining and surface finishing to match your design and performance needs. Contact us today to get a free CNC machining and surface treatment project quote!

In Conclusion

As an important method of metal surface treatment, brushed surface treatment technology is unique in that it can improve the appearance and actual functionality of the product at the same time. Compared with other surface treatment technologies, brushed treatment not only gives the metal surface a low-key and elegant visual effect by forming delicate textures or lines on its surface, but also enhances the surface’s wear resistance and anti-fingerprint performance, reflecting the harmonious unity of practicality and beauty.

Frequently Asked Questions About Brushing

Can All Metals be Brushed?

Not all metals are suitable for brushing. Brushing is mainly applicable to metals with certain plasticity and ductility, such as copper, aluminum, steel, stainless steel, aluminum alloys and brass. These metals can be stretched and extruded to form a slender filamentary structure during the brushing process, while changing their surface finish and hardness. However, for some metals with extremely high hardness or poor plasticity, brushing may be difficult or the processing effect may not be ideal.

What is the Surface Roughness of Brushing?

The roughness of the brushing surface is not a fixed value, but varies according to the specific machining conditions, metal materials and brushing process. Generally speaking, the average roughness of the brushing surface is between 0.2 and 1.0 microns, but it may also be in a wider range, such as 2-10 microns.

What is the Difference Between a Rrushed Finish and a Polished Finish?

The brushed finish is a process of mechanically rubbing the metal surface to form fine horizontal lines perpendicular to the length direction, which can also remove surface stains and flaws. The polished finish uses abrasives to polish the surface to make it smooth and shiny, and can also remove surface oxides, oxide scales, etc.