Can Sheet Metal Be Customized for Unique Designs?

Sheet metal can be customized to achieve unique designs through the use of advanced fabrication techniques such as CNC machining, laser cutting, and various surface treatments. Let’s explore how sheet metal customization works, its advantages, and its potential for unique designs.

Why Choose Aluminum Material For CNC Machining?

Aluminum is an excellent choice for CNC machining due to its lightweight nature, high strength-to-weight ratio, excellent machinability, and corrosion resistance. It offers cost-effectiveness, versatility, and superior finish quality, making it ideal for various industries including aerospace, automotive, and electronics.

Waterjet Cutting Nozzles: A Comprehensive Guide

Struggling to attain precision in cutting processes? Waterjet cutting nozzles provide unparalleled accuracy and versatility for various applications. Waterjet cutting nozzles are specialized components designed to channel high-pressure water, or a combination of water and abrasive materials, to achieve precise cuts across diverse materials.

Hard Chrome Plating Aluminum and Electroplating Aluminum

Hard chrome plating aluminum provides superior durability and wear resistance, while electroplating offers cost-effective solutions for aesthetic and functional purposes. Understanding the differences between the two processes is crucial for selecting the best option for your needs.

How Much Does Custom CNC Machining Cost?

CNC machining costs vary based on multiple factors, including material, part complexity, quantity, finishing, and delivery speed. Understanding these factors will give you an accurate picture of pricing.

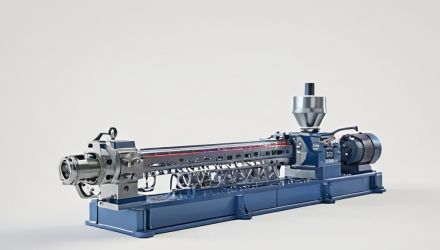

Advice on Compounding Extrusion

Compounding extrusion is a process that blends various polymers and additives to create customized materials. By prioritizing consistent quality, optimized mixing, efficient equipment use, temperature control, and material compatibility in composite extrusion, manufacturers can achieve reliable production results that meet their specific industry requirements.