Melting Point of Aluminum: CNC Machining Material Guide

The melting point of aluminum is 660.3°C (1220.5°F). Knowing this temperature helps avoid overheating, which can deform aluminum during machining, and ensures that the correct tools, feeds, and cooling systems are used.

Melting Point Of Silver: CNC Machining Material Guide

The melting point of silver is 962°C (1763°F), a temperature that enables its versatile use across multiple fields. From intricate jewelry designs to high-performance electronic parts, silver’s melting behavior is shaped by purity, alloying, and environmental factors, making it indispensable in modern applications.

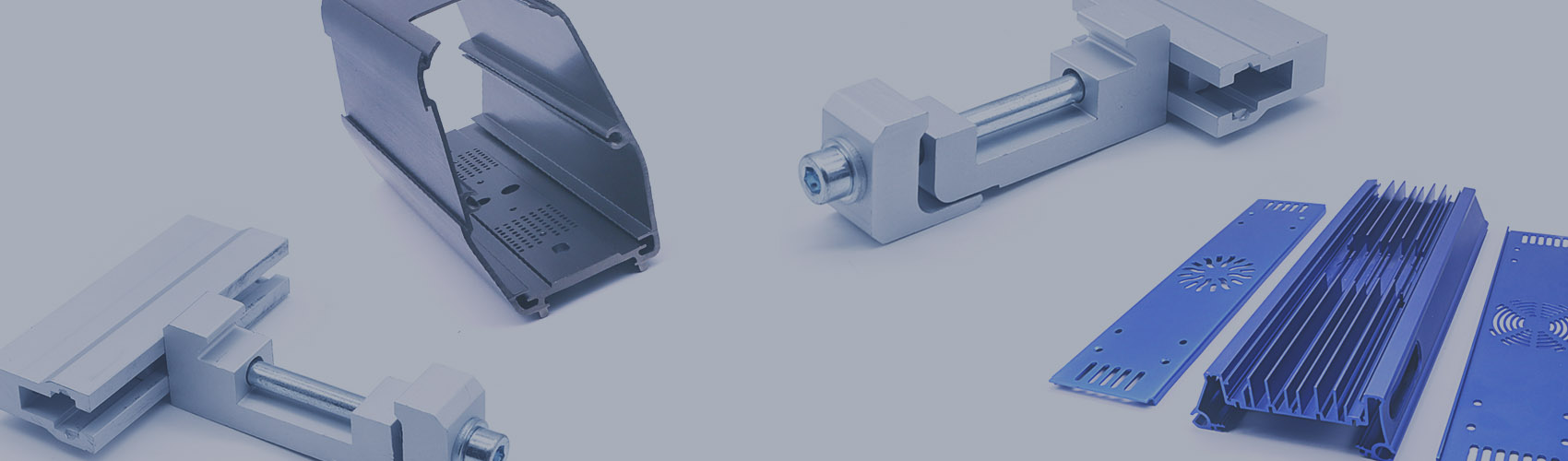

CNC vs Metal Additive Manufacturing: Everything You Need to Know

When deciding between CNC machining and metal additive manufacturing, it’s important to consider factors such as precision, material availability, production speed, and costs. CNC machining excels in high precision and large-scale production, while additive machining offers complex geometries and rapid prototyping capabilities.

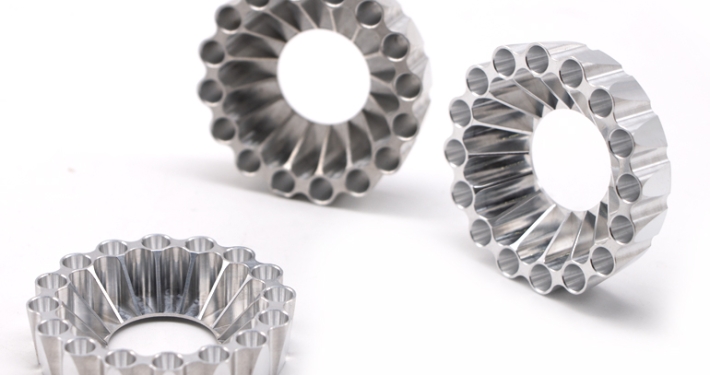

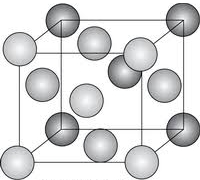

Crystal Structure and Strength of 6000 Series Aluminum

The 6000 series aluminum alloys, particularly 6061 and 6063, are highly sought after in CNC machining due to their excellent workability, weldability, and strength. Their crystal structure plays a pivotal role in their mechanical properties, making them ideal for diverse applications in industries such as construction, aerospace, and automotive.

The Mass Density of Copper: CNC Machining Material Guide

Mass density is defined as the mass of an object per unit volume. It is a fundamental property of materials and can be used to determine how much material is present in a given volume. Understanding copper’s density is essential for optimizing its use, as it influences weight, heat conductivity, and how copper interacts with other materials.

What Metal is Magnetic and Rusty? CNC Machining Material Guide

Certain metals, like iron and steel, are both magnetic and prone to rusting. This combination of properties affects CNC machining processes, material choice, and maintenance. Understanding how these properties interact is crucial for manufacturing high-performance parts with longevity.