Advantages of CNC Machining Auto Parts

CNC machining offers many benefits for the automotive industry, from precision and reliability to flexibility in production. These advantages make it one of the most widely used methods for producing high-quality auto parts.

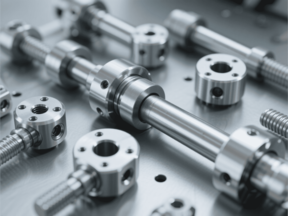

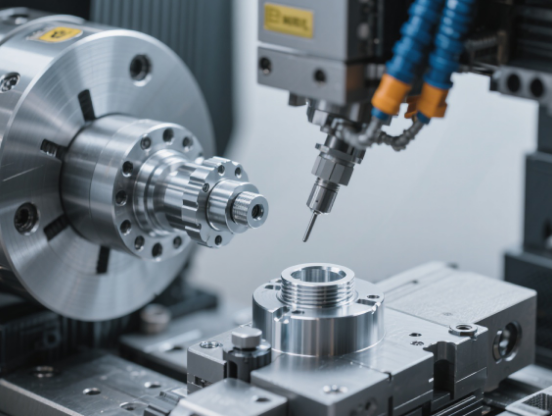

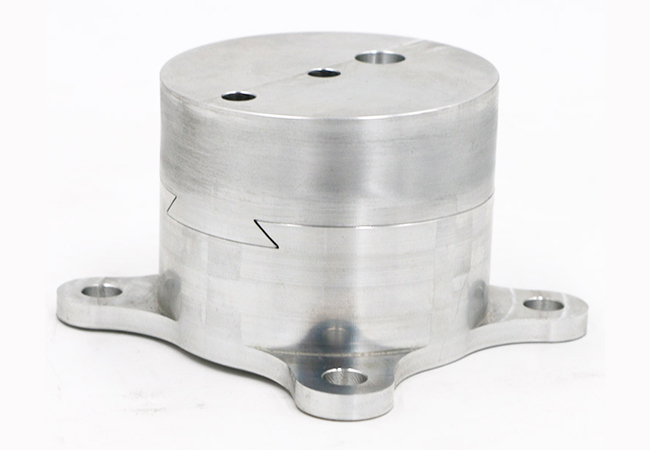

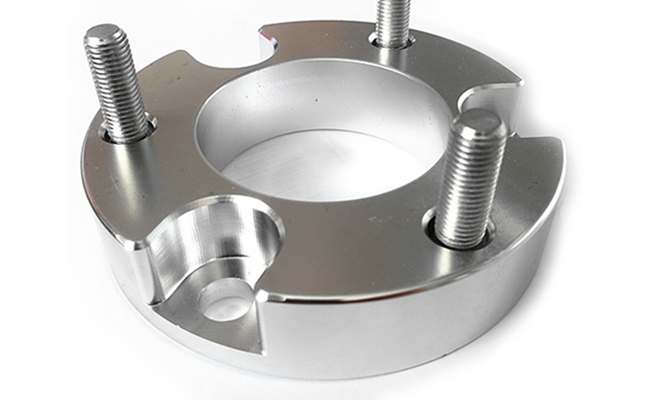

1. High Precision and Accuracy

CNC machining can produce parts with extremely tight tolerances. This ensures components fit and function correctly, which is especially critical for safety-related systems like brakes, steering, and engines.

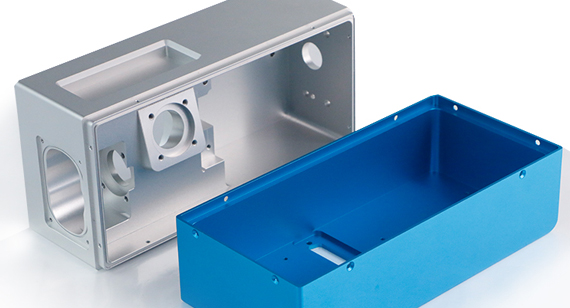

2. Consistency in Production

Once programmed, CNC machines can manufacture large quantities of identical parts with stable quality. This repeatability is essential for the mass production needs of the automotive industry.

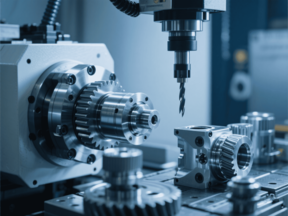

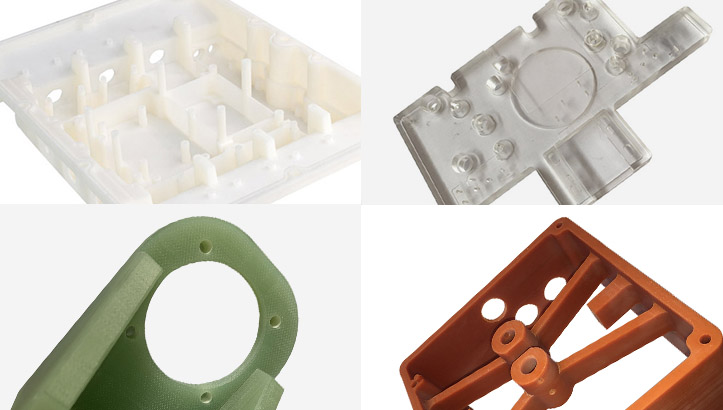

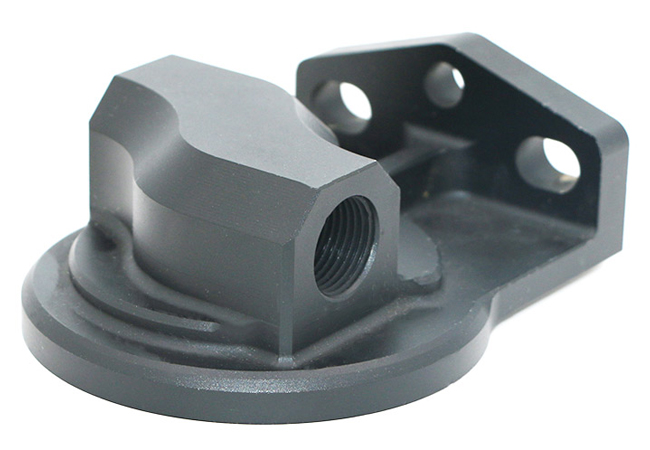

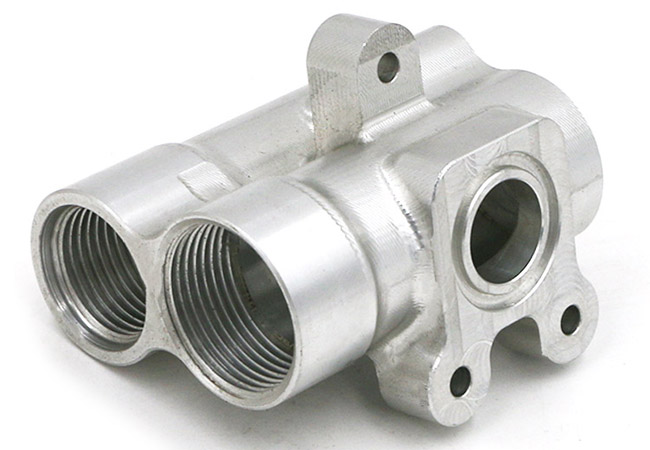

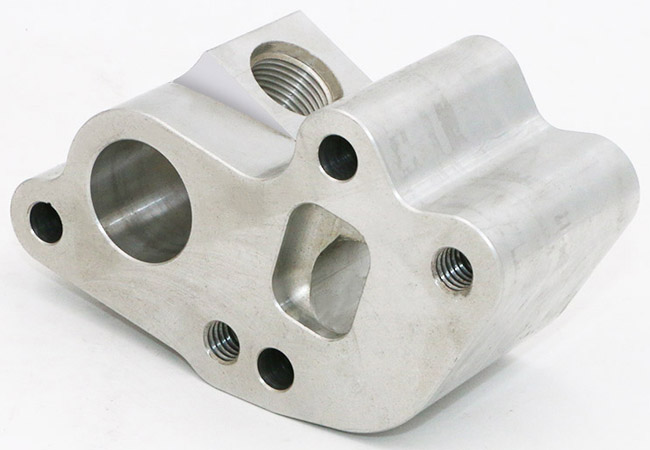

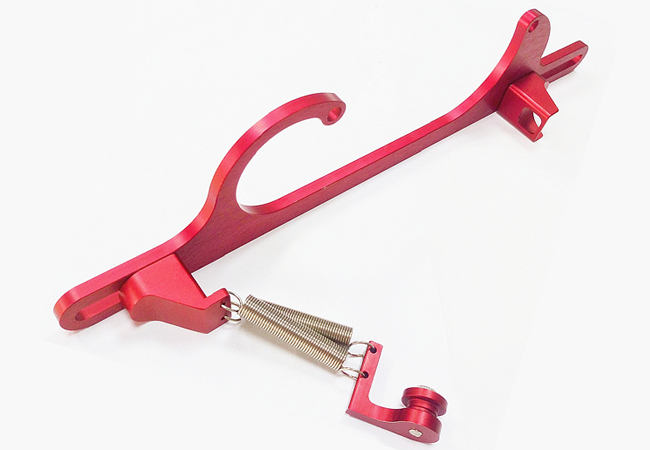

3. Complex Geometries

CNC machining is capable of creating complex shapes, fine details, and intricate designs that traditional manufacturing methods cannot achieve. This allows automakers to innovate in both performance and design.

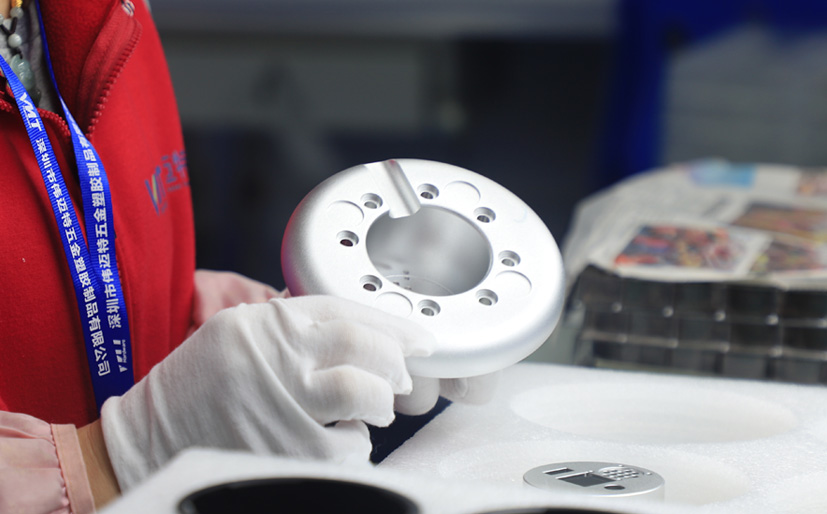

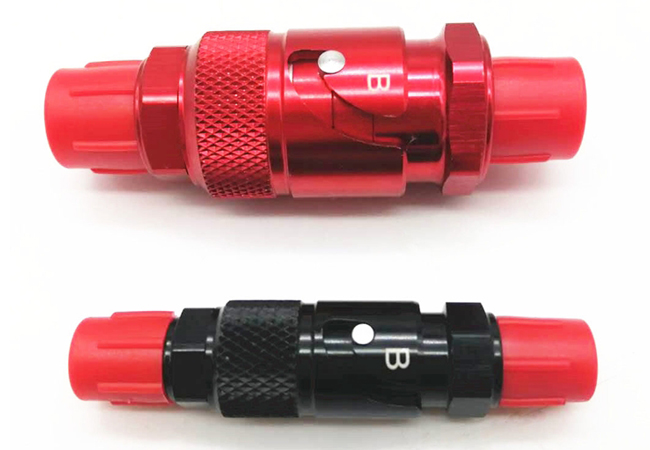

4. Wide Material Compatibility

From lightweight aluminum to durable stainless steel and engineering plastics, CNC machining supports a broad range of materials used in automotive parts. It also delivers excellent surface finishes.

5. Fast Prototyping and Short Lead Times

CNC machining is well suited for rapid prototyping. Engineers can quickly test, adjust, and refine designs, helping new vehicles and parts reach the market faster.