Are you struggling with complex material selection, tight tolerances, or ensuring consistent quality in your metal parts? Many companies find the aluminum extrusion process daunting, facing challenges in design optimization, production efficiency, and finding a reliable aluminum extrusion manufacturer. Nuances like creating precise extruded aluminum profiles and selecting the right surface finish can lead to project delays and compromise product integrity.

In an increasingly competitive market, mistakes in the metal extrusion process can lead to costly rework, missed deadlines, and ultimately, a damaged reputation. Generic solutions often fail to meet specific project needs, resulting in suboptimal aluminum extrusion profiles that meet your exact specifications or application requirements. You need a partner with in-depth knowledge of every aspect, from billet-to-bill extrusion to the most advanced aluminum extrusion applications.

VMT, an experienced aluminum extrusion manufacturer, offers comprehensive, expert-driven solutions for the aluminum extrusion process. Our advanced equipment, rigorous 12-level quality control, and deep engineering expertise ensure your aluminum extrusion dies can produce parts with accuracy as precise as ±0.005mm. Below we explore the specific processes of aluminum extrusion, from billet-to-billet extrusion to the most advanced applications of aluminum extrusion.

What is Aluminium Extrusion?

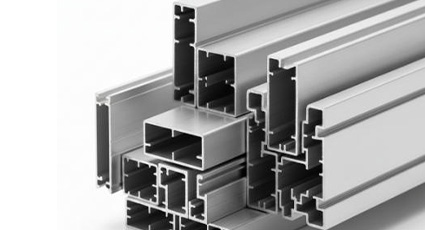

Aluminium extrusion is a fundamental manufacturing process that transforms aluminum alloy into objects with a definitive cross-sectional profile. This is achieved by forcing a heated aluminum billet through a specially designed die opening under significant pressure. The metal flows plastically, emerging as a continuous, elongated profile.

This process leverages aluminum’s unique combination of low density and high ductility when heated, allowing for the creation of complex shapes that would be challenging or impossible to achieve with other metal forming methods. The resultant aluminium extrusion retains the desired shape once cooled, ready for subsequent treatments.

Source: https://www.youtube.com/watch?v=baM5hNnBcT8

Why Choose the Aluminium Extrusion Process?

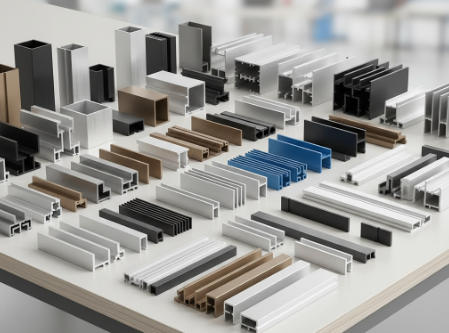

The primary advantage of the aluminium extrusion process lies in its ability to produce highly intricate and customized cross-sections with excellent dimensional accuracy. This offers unparalleled design flexibility, allowing engineers to integrate multiple functions into a single profile, reducing assembly steps and component count.

Furthermore, aluminum extrusions boast an exceptional strength-to-weight ratio, making them ideal for applications where weight reduction is critical, such as in the automotive and aerospace industries. This process also yields a smooth surface finish, which often requires minimal or no post-processing for aesthetic or functional purposes, further enhancing cost-effectiveness. The versatility of aluminium extrusion uses spans across construction, transportation, electronics, and consumer goods.

Detailed Steps of the Aluminum Extrusion Process

1. Aluminium Extrusion Raw Material Preparation: From Ingot to Billet

1.1. Aluminum Alloy Selection and Pre-treatment

The initial step involves meticulously selecting the appropriate aluminum alloy, typically from the 6xxx series (e.g., 6061, 6063, 6005), based on the desired mechanical properties, weldability, and surface finish of the final aluminum extrusion profiles. Each alloy possesses distinct characteristics that influence its extrudability and end-use performance, making informed selection critical.

Once selected, the raw aluminum, often in the form of cast ingots, undergoes a homogenization process. This thermal treatment ensures a uniform distribution of alloying elements throughout the material, which significantly improves its ductility and reduces die wear during the subsequent extrusion operation, leading to a more consistent product quality.

1.2. Heating and Temperature Control of the Billet

Before extrusion, the aluminum ingots are cut into billets of specific lengths and then preheated to a precise temperature, typically ranging from 400°C to 500°C (750°F to 930°F). This temperature renders the aluminum sufficiently plastic to flow through the die but prevents it from reaching its melting point of extruded state, which would compromise its structural integrity.

Accurate temperature control is paramount throughout this heating phase to ensure optimal metal flow characteristics and to prevent issues such as hot shortness or uneven material distribution. Modern extrusion facilities utilize advanced induction furnaces to achieve and maintain these exact temperatures, thereby optimizing the entire aluminium extrusion process.

2. Core Extrusion Process: Die and Forming

2.1. Aluminum Extrusion Die: Design, Materials, and Types

The aluminum extrusion die is the heart of the extrusion process, meticulously crafted to impart the desired cross-sectional shape to the aluminum. These dies are typically made from hardened tool steel, such as H13, capable of withstanding the immense pressures and temperatures encountered during operation.

Die design is a complex engineering discipline, taking into account factors like metal flow, heat dissipation, and the intricacy of the extruded aluminum shape. Dies can be solid for simple profiles, or hollow and semi-hollow designs which require more complex multi-piece dies incorporating mandrels to create internal cavities.

2.2. Application of Extrusion Force and Metal Flow

Once the preheated billet and die are in place, a hydraulic ram applies immense pressure—often exceeding 1000 tons—to the billet within the container. This force causes the plastic aluminum to flow through the opening of the aluminum extrusion.

As the aluminum exits the die, it takes on the exact shape of the die opening, creating the continuous extruded aluminum shape. The speed of this metal flow is carefully controlled to ensure uniform material distribution and to prevent surface defects, forming a critical aspect of the metal extrusion process.

3. Post-Extrusion Treatment: Cooling, Stretching, and Cutting

3.1. Quenching and Cooling Control

Immediately after exiting the die, the hot aluminum extrusion profiles are rapidly cooled, a process known as quenching. This crucial step “freezes” the metallurgical structure of the aluminum, preventing unwanted precipitation and ensuring the desired mechanical properties and temper are achieved.

The cooling rate is meticulously controlled using air or water, depending on the alloy and desired temper, to minimize distortion and internal stresses. Proper quenching is vital for developing the full strength potential of the aluminium extrusion, contributing significantly to its final performance characteristics.

3.2. Stretch Straightening and Dimensional Stability

Following quenching, the extruded profile, which may exhibit minor twisting or bowing due to cooling stresses, undergoes a stretching process. This involves gripping both ends of the profile and pulling it under tension, an operation that serves to straighten the profile and relieve residual stresses.

Stretch straightening is critical for achieving the tight dimensional tolerances and flatness required for high-precision applications. This step ensures that each define aluminum section meets the strict specifications necessary for its intended use, enhancing overall product quality and fit.

3.3. Precision Cutting and Preliminary Shaping

After stretching, the now straight and stress-relieved aluminum extrusion profiles are cut to specified lengths using a precision saw. This initial cutting transforms the continuous extruded length into manageable sections, ready for further processing.

These cut lengths can then undergo various preliminary shaping operations, such as minor bending or end-machining, depending on the final product requirements. This stage prepares the profiles for subsequent deep processing or direct integration into assemblies, streamlining the manufacturing workflow.

4. Surface Treatment and Deep Processing

4.1. Anodizing, Powder Coating, and Other Surface Enhancements

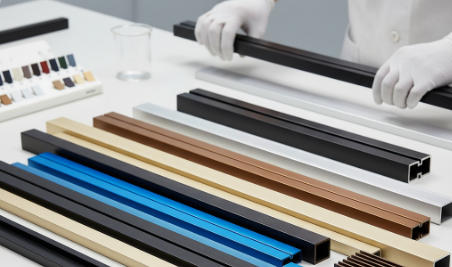

To enhance corrosion resistance, wear resistance, and aesthetic appeal, aluminum extrusion profiles often undergo various surface treatments. Anodizing is a common electrochemical process that creates a durable, protective oxide layer on the aluminum surface, which can also be dyed for decorative purposes.

Alternatively, powder coating involves applying a dry powder that is then cured under heat, forming a hard, durable, and colorful finish. Other options include painting, polishing, and brushing, each offering distinct visual and functional benefits tailored to specific aluminium extrusion uses.

4.2. Mechanical Machining and Assembly

Beyond surface treatments, extruded aluminum frequently require additional mechanical machining to create specific features, such as holes, slots, threads, or complex contours. Processes like drilling, milling, tapping, and CNC machining are employed to achieve these precise modifications.

Finally, these processed aluminum extrusions can be assembled with other components using methods like welding, riveting, or fastening, to form complete products or sub-assemblies. This comprehensive deep processing capability underscores the versatility of the aluminium extrusion process in modern manufacturing.

Detailed Steps of the Aluminum Extrusion Process

| Step | Stage | Description |

| 1 Raw Material Preparation: From Ingot to Billet | 1.1 Alloy Selection & Pre-treatment | Select the appropriate alloy (commonly 6xxx series: 6061, 6063, 6005) based on required strength, weldability, and finish. Cast ingots undergo homogenization heat treatment to ensure uniform microstructure, improved ductility, and reduced die wear. |

| 1.2 Billet Heating & Temperature Control | Ingots are cut into billets and preheated to 400°C–500°C (750°F–930°F). Accurate temperature control ensures good plastic flow without melting, preventing structural weakness. Modern extrusion lines use induction furnaces for precision heating. | |

| 2. Core Extrusion Process: Die & Forming | 2.1 Extrusion Die Design & Types | Dies, usually made from hardened tool steel (H13), withstand extreme pressure and heat. Design must account for metal flow, heat dissipation, and profile complexity. Types include solid, hollow, and semi-hollow dies. |

| 2.2 Extrusion Force & Metal Flow | A hydraulic ram applies pressure (often >1000 tons) to push the billet through the die opening. The aluminum takes the die’s cross-sectional shape. Flow speed must be carefully controlled to ensure surface quality and dimensional consistency. | |

| 3 Post-Extrusion Treatment: Cooling, Stretching & Cutting | 3.1 Quenching & Cooling | As the profile exits the die, it is rapidly cooled by air or water to “freeze” the microstructure and achieve the required temper (e.g., T5, T6). Controlled cooling prevents distortion and ensures strength. |

| 3.2 Stretch Straightening & Dimensional Stability | Quenched profiles may warp slightly. They are gripped and stretched to straighten and relieve residual stress, achieving precise tolerances and flatness. | |

| 3.3 Precision Cutting & Pre-shaping | Straightened profiles are cut to specified lengths with precision saws. Pre-bending or end-machining may follow, preparing sections for deeper processing or assembly. | |

| 4 Surface Treatment & Deep Processing | 4.1 Surface Enhancements | Common options: anodizing, powder coating, painting, polishing, and brushing — each offering different protective and decorative effects. |

| 4.2 Machining & Assembly | Profiles may undergo drilling, milling, tapping, or CNC machining for precision features. They can then be welded, riveted, or fastened with other components to form finished products or fastened with other components to form finished products or subassemblies. |

Surface Treatment Methods for Extruded Aluminum Profiles

Final aluminum extrusions often require specialized surface treatments to enhance their performance, durability, and visual appeal for specific aluminum extrusion applications. With over 50 SQE-certified surface treatment partners, we offer a wide range of advanced surface treatment options. We consider these processes an integral part of the aluminum extrusion process.

We possess core technical expertise in key areas, such as hard anodizing dimensional reserve, a crucial consideration for maintaining tight tolerances. We also offer systematic solutions for common issues such as oxidation streaks and material lines in 7075 aluminum extrusion raw material. This ensures your aluminum extrusions have a flawless finish. Here are some of our common surface treatments for aluminum extrusions:

| Surface Treatment Option | Key Benefit | Common Applications for Aluminium Extrusion Profiles |

|---|---|---|

| Anodizing | Enhanced corrosion resistance, improved aesthetics, electrical insulation. | Architectural components, consumer electronics, decorative extruded aluminum. |

| Hard Anodizing | Superior wear resistance, increased hardness, excellent insulation. | Industrial machinery parts, military components, high-friction aluminium extrusion uses. |

| Micro-Arc Oxidation | High hardness, outstanding wear and corrosion resistance, good thermal insulation. | Aerospace, medical devices, extreme environment aluminum extrusion profiles. |

| Sandblasting | Uniform matte finish, prepares surface for painting or further treatment. | Architectural facade elements, aesthetic finishes for extruded aluminum. |

| Brushing | Distinctive directional satin finish, aesthetic appeal. | Consumer electronics casings, decorative panels for aluminium extrusion profiles. |

| Polishing | High gloss, reflective finish, improved cleanliness. | Automotive trim, highly visible aesthetic extruded aluminum. |

| Conductive Oxidation | Excellent electrical conductivity, corrosion protection. | EMI shielding for electronics, electrical contact surfaces. |

| Electroplating | Adds a layer of another metal for specific properties. | Decorative aluminium extrusion uses, improved wear or corrosion resistance. |

| Passivation | Enhances corrosion resistance by removing free iron from stainless steel. | Medical instruments, food processing equipment (though primarily for stainless steel, often discussed in multi-metal contexts). |

| PVD | Hard, durable, decorative coatings with various colors and properties. | Luxury goods, tooling, medical implants, high-performance aluminum extrusion profiles. |

| Heat Treatment | Alters mechanical properties of the `aluminium extrusion raw material`. | Structural components, parts requiring specific yield strength. |

VMT’s Comprehensive Support for Aluminium Extrusion Clients

At VMT, our commitment to your project extends beyond the mere production of extruded aluminum profiles. We strive to be a complete solution provider, offering expert technical support, flexible business terms, and unwavering intellectual property protection.

In Conclusion

The aluminum extrusion process is a cornerstone of modern manufacturing, combining design flexibility, excellent strength-to-weight ratio, and cost efficiency. It enables the production of complex profiles with high precision, making it essential in industries ranging from architecture to aerospace. Contact us today for your free aluminum extrusion project!

Frequently Asked Questions

What types of aluminum alloys are commonly used in extrusion?

Common alloys for aluminium extrusion include the 6xxx series, such as 6061 and 6063, which offer excellent extrudability, good strength, and corrosion resistance, making them suitable for a wide range of applications.

How does anodizing enhance extruded aluminum profiles?

Anodizing creates a durable, corrosion-resistant oxide layer on the surface of aluminum extrusion profiles, which significantly improves wear resistance, protects against environmental factors, and allows for various aesthetic finishes including color.

What is the typical lead time for VMT custom aluminum extrusions?

The lead time for custom aluminium extrusion profiles can vary significantly based on die complexity, order volume, and the manufacturer’s current capacity, typically ranging from 4-8 weeks for new tooling and initial production run.

What is the primary difference between aluminum extrusion and die casting?

The main differences lie in the state of the material and the forming method. Aluminum extrusion involves pushing a heated, solid aluminum billet through a die to create a continuous profile with a uniform cross-section.

Die casting, on the other hand, injects molten metal into a die under high pressure, creating complex, often thin-walled parts. While aluminum extrusion excels at producing consistent, continuous aluminum extrusions, die casting is better suited for producing complex, three-dimensional shapes.

What is the melting point of extruded aluminum alloys?

The melting point of extruded aluminum alloys varies depending on the specific alloy composition, but generally falls within a range of approximately 600°C (1112°F) to 660°C (1220°F). Pure aluminum melts at about 660°C. Alloying elements like silicon, magnesium, and copper are added to enhance properties, which slightly lower the melting point compared to pure aluminum. The extrusion process itself occurs at temperatures well below the melting point, where the metal is in a plastic, deformable state.