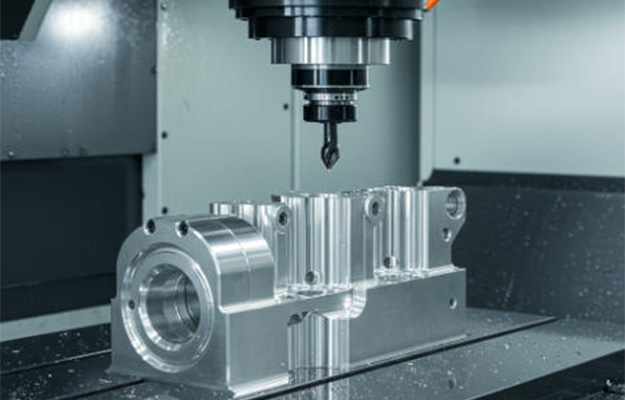

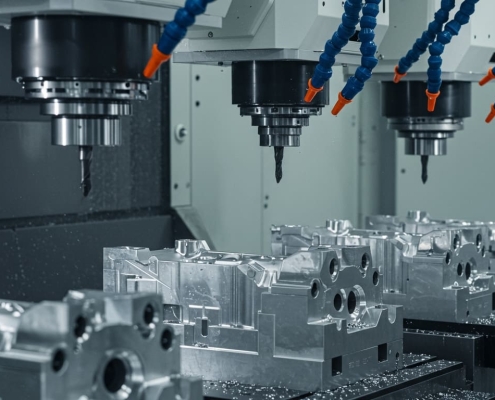

CNC machining aluminum is a subtractive manufacturing process that utilizes computer numerical control to precisely shape aluminum alloys into desired components. It leverages high-speed rotational cutting tools to remove material from a solid aluminum block, achieving intricate geometries and tight tolerances.

Are you searching for a reliable CNC Machining manufacturer, but constantly facing challenges like delivery delays, inconsistent quality, or substandard surface finishes? We understand the critical importance of finding a trusted CNC Machining Aluminum service provider for your project in this competitive market. This article will provide an in-depth analysis of all aspects of CNC Machining Aluminum, helping you make informed decisions and ensure your products meet exceptional standards from design to delivery.

What is CNC Machining Aluminum?

CNC Machining Aluminum is a highly precise subtractive manufacturing method that uses computer numerical control systems to automate the machining process. This technique involves removing material from a solid block of basic aluminum, or an aluminum alloy, using various cutting tools to achieve the desired shape. The digital control allows for exceptional accuracy and repeatability, making it indispensable for modern manufacturing.

Our experience as a CNC Machining manufacturer shows that this process is foundational for producing components with complex geometries and stringent tolerance requirements. From prototype development to high-volume production, CNC Machining Aluminum delivers consistent results across diverse industries. We utilize advanced machinery to ensure every part meets exact specifications.

What Types of Aluminum are Used in CNC Machining?

Choosing the correct type of aluminum for CNC machining is a critical decision that impacts material properties, machinability, and the final application. Aluminum alloys are broadly categorized by their primary alloying elements, influencing characteristics like strength, corrosion resistance, weldability, and heat treatability. These distinctions are vital when you consider a CNC Machining Aluminum service.

For instance, some alloys are designed for high strength, while others prioritize formability or aesthetic appeal after various surface treatments. Understanding these differences allows us to guide you toward the optimal material choice for your specific project, ensuring performance and cost-efficiency. Our expertise as a CNC Machining manufacturer from China includes working with a vast array of aluminum types.

Understanding Aluminum Series for CNC Machining Aluminum

Aluminum alloys are grouped into series, each designated by a four-digit number, indicating their primary alloying elements. These series determine the general characteristics and suitability for specific applications in CNC Machining Aluminum. We find this classification system highly useful for initial material selection discussions with our clients.

The most common series encountered in precision machining include the 2xxx, 5xxx, 6xxx, and 7xxx series, each offering distinct advantages. Selecting the appropriate series is the first step towards a successful CNC machining project, directly influencing the component’s performance. Our CNC Machining Aluminum service focuses on precise material matching. The following is the common aluminum series for CNC machining:

| Alloy Series | Primary Alloying Element | Key Characteristics | Typical Applications |

|---|---|---|---|

| 1xxx | Pure Aluminum | Excellent corrosion resistance, high electrical/thermal conductivity | Electrical conductors, chemical equipment |

| 2xxx | Copper | High strength, good machinability, heat treatable | Aerospace components, military equipment |

| 5xxx | Magnesium | Good corrosion resistance (esp. seawater), weldable | Marine applications, pressure vessels |

| 6xxx | Magnesium & Silicon | Good strength, excellent corrosion resistance, heat treatable, good machinability | Structural components, automotive parts, bicycle frames |

| 7xxx | Zinc | Very high strength, heat treatable | Aerospace, high-performance sports equipment |

Most Common Aluminum Alloys for Aluminum Machining.

Within the various series, several specific aluminum alloys stand out as favorites for CNC machining due to their balance of properties and ease of processing. Our experience as a CNC Machining manufacturer highlights their widespread use in demanding applications. We consistently recommend these alloys to clients seeking reliable performance from our CNC Machining Aluminum service.

These alloys offer a combination of strength, machinability, and finishing capabilities that are highly desirable for precision components. Selecting the right alloy ensures both the integrity of the final product and the efficiency of the manufacturing process.

1. 6061-T6 Aluminum

6061-T6 is the most widely used aluminum alloy for CNC machining thanks to its balanced properties. It combines a high strength-to-weight ratio, excellent corrosion resistance, and superior machinability. The T6 temper further enhances its mechanical performance, making it a top choice for structural components, jigs, fixtures, and consumer electronics enclosures. Its versatility explains why many clients specifically request 6061-T6 aluminum CNC machining.

2. 2024 Aluminum

2024 aluminum is known for its outstanding strength and fatigue resistance, which makes it ideal for demanding, high-stress environments. While its corrosion resistance is only fair and weldability is limited, it remains a preferred choice for aerospace structures, fasteners, and military applications where strength is critical.

3. 5052 Aluminum

5052 is often selected for applications that require excellent corrosion resistance, especially in marine or saltwater environments. It also offers very good formability and weldability, making it suitable for marine components, fuel tanks, and electronic chassis. Though its machinability is only moderate, its durability in harsh environments makes it indispensable for specific projects.

4. 7075 Aluminum

7075 is one of the strongest aluminum alloys available for CNC machining. With excellent fatigue resistance and heat-treatable properties, it is commonly used for aerospace fittings, gears, missile components, and other high-stress parts. However, its weldability is poor, and corrosion resistance is not as high as 5052 or 6061, so it is typically chosen when strength is the overriding requirement.

Benefits of CNC Machining Aluminum

The combination of aluminum’s material properties and the precision of CNC machining makes it one of the most widely used options for high-performance components. At VMT, we leverage these advantages to deliver lightweight, durable, and cost-effective solutions across medical, aerospace, automotive, and electronics industries. The key benefits include:

| Benefit | Description |

|---|---|

| Superior Strength-to-Weight Ratio | Aluminum combines high strength with low density, making it ideal for weight-sensitive applications such as aerospace, automotive, and drones. CNC machining ensures lightweight yet durable parts that enhance performance and fuel efficiency. |

| Excellent Corrosion Resistance | A natural oxide layer protects aluminum against corrosion in most environments. This reduces the need for additional coatings, though anodizing can further improve durability and aesthetics. Our machining and finishing services ensure long-lasting performance. |

| High Thermal & Electrical Conductivity | Aluminum’s excellent conductivity makes it suitable for heat sinks, electronic housings, and connectors. CNC precision enables intricate designs that maximize heat dissipation and current flow while maintaining structural integrity. |

| Cost-Effectiveness & Machinability | Aluminum is affordable and easy to machine, with fast material removal rates and extended tool life. This reduces production costs and lead times, making it ideal for both rapid prototyping and large-scale manufacturing. |

In Conclusion

This guide comprehensively explores the diverse world of CNC aluminum machining, from selecting the most commonly machined aluminum alloys to the advantages and ensuring strong after-sales support.

Your search for high-quality CNC aluminum machining services requires informed decisions and a trusted partner. By understanding the processes, materials, and benefits outlined in this article, you’ll be better equipped to navigate this complex landscape. We invite you to choose VMT’s expertise as a leading CNC aluminum machining service provider in China. Contact us today to discuss your next project and experience our commitment to precision, quality, and timely delivery.

Frequently Asked Questions

What considerations are critical when selecting a CNC Machining manufacturer for aluminum parts?

When selecting a CNC Machining manufacturer for your aluminum parts, you should prioritize several key factors. Expertise with various aluminum alloys is crucial, as is a proven track record for precision and quality. Look for a CNC Machining service that demonstrates advanced equipment, comprehensive quality control procedures, and transparent communication regarding lead times and project status. Our facility in China, for example, combines state-of-the-art machinery with rigorous quality management systems.

How does VMT ensure quality control for CNC Machining Aluminum components?

At VMT, our quality control for CNC Machining Aluminum components begins at material sourcing, verifying the integrity of basic aluminum and specified alloys. We employ advanced CMMs and optical inspection tools for in-process and final inspections to ensure dimensional accuracy and adherence to tolerances. Our quality assurance team implements strict protocols, from first-article inspection to batch sampling, ensuring every component from our CNC Machining Aluminum service meets your exact specifications.

Can CNC Machining Aluminum achieve very tight tolerances, and what are typical capabilities?

Yes, CNC Machining Aluminum can achieve very tight tolerances, often down to +/- 0.005mm or even finer, depending on the machine, tooling, and alloy type. For demanding applications like aerospace or medical devices, high-precision 5-axis CNC machines and specialized cutting strategies are employed.

What are the typical lead times for CNC Machining Aluminum projects?

Lead times for CNC Machining Aluminum projects vary significantly based on complexity, quantity, material availability, and current production load. For prototypes, lead times can be as short as a few days to a week. For larger production runs, it might range from 2 to 4 weeks, including any required surface treatments. As a CNC Machining service in China, we leverage efficient workflows and strategic material procurement to offer competitive lead times, always striving to meet your project deadlines.

What Surface Finishes Are Available for CNC Machined Aluminum Parts, and How Do They Impact the Final Product?

A wide range of surface finishes can be applied to CNC machined aluminum parts, each influencing aesthetics, durability, and functionality. Common options include clear or colored anodizing, hardcoat anodizing, bead blasting, and polishing. These treatments enhance wear resistance, chemical stability, corrosion protection, and overall visual appearance. At VMT, we help you select the most suitable finish to meet both technical requirements and design preferences for your aluminum components.