Is 7075 Aluminum Stronger Than Steel?

Many industries struggle when deciding between 7075 aluminum and steel for applications requiring high strength and durability. Choosing the wrong material can lead to increased costs, mechanical failures, or inefficient production processes. So, is 7075 aluminum stronger than steel? This article explores the properties, composition, and applications of 7075 aluminum and steel to determine which material is the better choice for different use cases.

7075 aluminum is one of the strongest aluminum alloys available, with a tensile strength of 7075 aluminum that can rival certain steels. However, is steel harder than aluminum? Generally, steel offers greater hardness and wear resistance. The best material depends on the application and required properties.

What is Aluminum Alloy?

An aluminum alloy is a metal material made by adding elements such as copper, magnesium, silicon, zinc, or manganese to aluminum to enhance its mechanical properties. It is lightweight, strong, highly resistant to corrosion, and offers excellent thermal and electrical conductivity. Aluminum alloys are easy to process and recyclable, making them both versatile and sustainable. Classified into wrought alloys and cast alloys based on production methods, they are widely used in aerospace, automotive, construction, packaging, and electronics, playing a vital role in modern industry.

Alloy Composition of 7075 Aluminum

The composition of 7075 aluminum consists of approximately 90% aluminum, 5.6% zinc, 2.5% magnesium, 1.6% copper, and 0.23% chromium, along with trace amounts of other elements. This precise combination provides the alloy with exceptional strength, making it one of the strongest aluminum alloys available. It also offers good fatigue resistance, moderate corrosion resistance, and excellent machinability, making it ideal for aerospace, automotive, and military applications where high performance and reliability are essential.

Characteristics of 7075 Aluminum

High Strength: The yield strength of 7075 aluminum is significantly higher than that of many other aluminum alloys, making it suitable for high-stress structural applications such as aerospace and automotive components.

Good Machinability: This alloy is relatively easy to process and machine, providing efficient fabrication capabilities while maintaining its mechanical properties, often outperforming certain steels in machinability.

Moderate Corrosion Resistance: While 7075 aluminum has some resistance to corrosion, it is not as corrosion-resistant as other alloys like 6061. In harsh or marine environments, protective coatings or anodizing are recommended to enhance durability.

Lightweight: With a density much lower than steel, 7075 aluminum combines its strength with a lightweight profile, making it ideal for applications where weight reduction is crucial.

Fatigue Resistance: The alloy exhibits excellent resistance to fatigue under cyclic stress, which is critical for applications like aircraft structures and sporting equipment.

Heat Treatable: 7075 aluminum can be heat-treated to achieve higher strength and specific mechanical properties, offering versatility in its applications.

How Strong is 7075 Aluminum?

The 7075 aluminum alloy, particularly in the T6 temper, is renowned for its exceptional strength. Its yield strength is approximately 503 MPa, which is significantly higher than most other aluminum alloys, and its tensile strength can reach up to 572 MPa, making it one of the strongest commercially available aluminum alloys. This remarkable strength-to-weight ratio is comparable to that of some steels, yet 7075 aluminum is much lighter.

Additionally, the alloy maintains its strength even under extreme conditions and demonstrates good fatigue resistance, making it ideal for high-performance applications in aerospace, automotive, military, and sporting industries. However, its strength comes with slightly reduced corrosion resistance compared to other alloys, requiring protective treatments in certain environments.

Applications of 7075 Aluminum

7075 aluminum is renowned for its exceptional strength, lightweight properties, and fatigue resistance, making it a preferred material in industries requiring high performance and durability. Below are the detailed applications across various fields:

1. Aerospace Industry

Due to its high strength-to-weight ratio and excellent fatigue resistance, 7075 aluminum is extensively used in aerospace applications. It is a key material for manufacturing critical aircraft components such as fuselage frames, wing spars, and landing gear, ensuring structural integrity under extreme conditions.

2. Automotive Components

In the automotive sector, 7075 aluminum is favored for high-performance and racing vehicles. It is utilized in components such as suspension systems, drive shafts, and structural parts, offering enhanced durability, reduced weight, and improved fuel efficiency.

3. Military-Grade Equipment

7075 aluminum’s strength and toughness make it suitable for demanding military applications. It is used in the production of armored vehicles, firearms, missile components, and other equipment where high durability and reduced weight are essential for field operations.

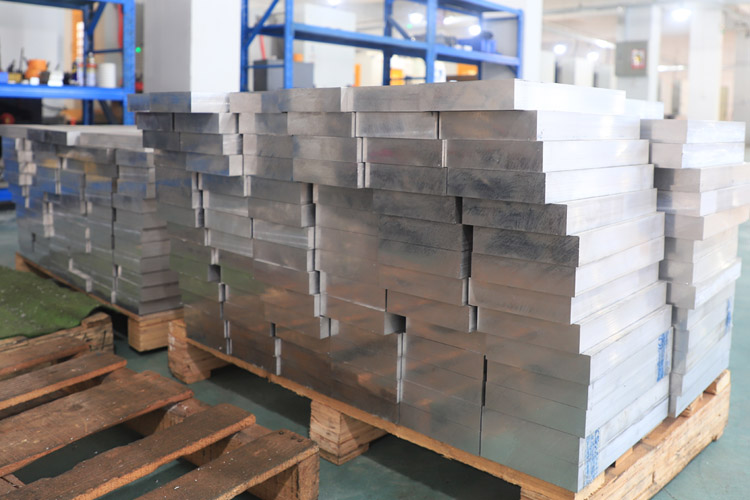

5. Industrial Tooling and Molds

Its high strength and machinability make 7075 aluminum an excellent material for creating industrial tooling, molds, and fixtures. These tools must endure significant mechanical stress while maintaining precision and reliability.

6. Electronics and Robotics

The combination of strength and low weight makes 7075 aluminum suitable for structural components in electronics, drones, and robotic systems. It supports mobility, efficiency, and performance in advanced technology applications.

With its versatile applications, 7075 aluminum plays a vital role in industries that demand a unique balance of strength, lightweight properties, and durability.

What is Steel Alloy?

A steel alloy is a material primarily composed of iron and carbon, with the carbon content typically ranging between 0.02% and 2.14%. To further enhance its mechanical, chemical, and physical properties, additional elements such as chromium, nickel, molybdenum, manganese, vanadium, and silicon are often added. These alloying elements are included in varying amounts to achieve specific characteristics and meet the requirements of diverse applications.

Different Types of Steel

Steel comes in various types, each engineered with specific properties to meet the needs of different applications. The primary types of steel include carbon steel, stainless steel, alloy steel, and tool steel.

Carbon Steel

Composed of iron and carbon, carbon steel is known for its strength and hardness. It is divided into:

- Low Carbon Steel: Flexible and easy to form, used in construction.

- Medium Carbon Steel: Offers strength and ductility, used in machinery parts.

- High Carbon Steel: Hard and wear-resistant, used for tools and springs.

Stainless Steel

Alloyed with at least 10.5% chromium, stainless steel is corrosion-resistant and comes in:

- Austenitic: Corrosion-resistant, used in kitchenware and medical tools.

- Ferritic: Magnetic and stress-resistant, used in exhaust systems.

- Martensitic: Hard and strong, used in tools and knives.

Alloy Steel

Contains additional elements like chromium and nickel to improve strength, toughness, and wear resistance.

Tool Steel

Designed for high hardness and heat resistance, it is used in cutting tools and molds.

- High-Speed Steel (HSS): Retains hardness at high temperatures.

- Cold Work Steel: Used for shaping and cutting materials at low temperatures.

7075 Aluminum and Steel Chemical Properties

7075 aluminum is an alloy primarily composed of aluminum, zinc, magnesium, copper, and chromium. The high zinc content significantly enhances its strength, making it one of the strongest aluminum alloys available, while copper adds hardness. This composition provides excellent strength-to-weight ratios and fatigue resistance, but it is more prone to corrosion compared to other aluminum alloys, requiring protective coatings in some applications.

In contrast, steel is primarily composed of iron and carbon, with various alloying elements such as manganese, chromium, nickel, and molybdenum. Carbon plays a crucial role in improving hardness and wear resistance, while the addition of elements like chromium and nickel can enhance corrosion resistance and toughness. Steel is highly versatile, with different alloy compositions tailored to applications requiring strength, durability, and resistance to wear and corrosion.

7075 Aluminum and Steel Physical Properties Chart

| Property | 7075 Aluminum | Steel |

|---|---|---|

| Density | 2.81 g/cm³ | 7.85 g/cm³ |

| Tensile Strength | 572 MPa | 400-550 MPa (varies by type) |

| Yield Strength | 503 MPa | 250-500 MPa (varies by type) |

| Hardness | 150 Brinell | 150-300 Brinell (varies by type) |

Is 7075 Aluminum Stronger Than Steel?

While 7075 aluminum is one of the strongest aluminum alloys, with impressive strength-to-weight ratios, it is generally not as strong as high-carbon or alloy steels. With a yield strength of around 503 MPa and a tensile strength up to 572 MPa, 7075 aluminum can match or exceed the strength of mild steel. However, high-carbon and alloy steels can reach significantly higher strengths, with some high-carbon steels exceeding 1,200 MPa in yield strength and 1,500 MPa in tensile strength. Therefore, while 7075 aluminum is ideal for applications requiring both strength and lightness, steel typically offers superior strength, hardness, and wear resistance for more demanding applications.

7075 Aluminum vs Steel: Mechanical Properties

7075 aluminum is known for its high strength-to-weight ratio, making it ideal for lightweight yet strong applications like aerospace and automotive components. While its tensile strength of up to 572 MPa is comparable to some steels, the low density of aluminum means it is much lighter, offering advantages in situations where weight reduction is critical. This makes 7075 aluminum a preferred choice in industries where high strength and low weight are essential, such as in aircraft structures and high-performance vehicles.

In comparison, steel is typically harder and more wear-resistant than aluminum. The carbon content in steel gives it superior tensile strength and durability under stress and in abrasive environments. Steel alloys, especially high-carbon and alloy steels, can achieve tensile strengths of 1,200 MPa or more, far surpassing 7075 aluminum. While steel’s weight makes it less ideal for weight-sensitive applications, its superior hardness, strength, and resistance to wear and fatigue make it a top choice for heavy-duty machinery, structural components, and tools.

Frequently Asked Questions About 7075 Aluminum And Steel

How Does the Strength of 7075 Aluminum Compare to Steel?

In terms of tensile strength steel vs aluminum, 7075 aluminum competes well with lower-strength steels but does not match hardened or tool steels in overall toughness and wear resistance.

7075 Billet Aluminum vs 4140 Steel

7075 aluminum, especially in billet form, is lightweight and offers good corrosion resistance, making it ideal for aerospace, automotive, and high-performance machinery where both strength and reduced weight are crucial. Its high strength-to-weight ratio is advantageous in projects requiring strength and lightness, though it may need protective coatings for better durability.

4140 steel, a high-carbon alloy steel, is stronger and has better wear resistance than 7075 aluminum, making it suitable for heavy loads and high-friction environments. Common in automotive and industrial applications, it offers superior strength and durability, but it is much heavier than aluminum.

Aluminum vs Steel Strength-to-Weight Ratio

Aluminum is significantly lighter than steel, with only about one-third of its density, making it ideal for weight-sensitive applications like aircraft and lightweight vehicles.

While steel is stronger overall, aluminum provides better strength-to-weight ratio, offering strength without the added weight. This makes aluminum a top choice for applications that need both strength and low weight, where steel’s weight might be a disadvantage.