VMT’s blogs aim to share our practical experience and knowledge accumulated during the manufacturing and product development process. Our goal is to use these articles to help you improve product design and increase your understanding of CNC machining, 3D printing, rapid prototyping, low-volume manufacturing, and surface treatment technologies. The information we provide is designed to provide actionable guidance and insights for your CNC machining projects.

Principles and Applications of Sandblasting

Among the complex and changeable surface finishing processes, sandblasting can be said to be a very important surface treatment process. Although sandblasting may still seem relatively unfamiliar to many people, in fact, it plays an important role in various fields due to its efficiency and flexibility. This article will unveil the mystery of sandblasting for you and gain an in-depth understanding of its principles and applications.

What is Sandblasting?

Sandblasting is a surface finishing process that uses compressed air to propel abrasive materials, such as quartz sand, emery, iron sand, or Hainan sand, at high speed onto the surface of a workpiece. This technique is used to clean the surface, remove tiny burrs, increase surface roughness, and enhance mechanical properties. It also helps achieve various reflective or matte finishes, depending on the specific requirements of the part.

Basic Principles of Sandblasting.

Sandblasting is a surface treatment process that uses high-pressure air or water to accelerate and propel abrasive materials, such as quartz sand or steel shot, onto the surface of a workpiece. The impact and cutting action of the abrasives help remove oxide scale, rust, dirt, and old coatings from the workpiece’s surface.

This process also improves surface roughness, enhances adhesion, and prepares the surface for subsequent treatments, such as spraying or electroplating. Additionally, sandblasting can improve the wear resistance and fatigue resistance of parts. In CNC machining, sandblasting is commonly applied during pre- or post-processing stages to enhance the final quality of the workpiece.

Sandblasting Process.

Pretreatment: Clean the surface of the workpiece to remove oil, dust and other impurities to ensure the sandblasting effect.

Select sand material: Select the appropriate sand material according to the material of the workpiece and the purpose of processing. For example, for precision CNC machining parts, finer sand particles may be selected to reduce excessive damage to the surface.

Sandblasting operation: The sand material is sprayed to the surface of the workpiece through a sandblasting machine at high pressure, and the treatment effect is controlled by adjusting the sandblasting pressure, angle and speed.

Post-processing: Clean the remaining sand, check the sandblasting quality, and perform secondary treatment or apply a protective layer if necessary.

Quality inspection: Conduct appearance inspection, roughness measurement, etc. on the workpiece after sandblasting to ensure that it meets the processing requirements.

What are the Commonly Used Sandblasting Materials?

Quartz sand: High hardness, suitable for cleaning oxide scale and rust on the surface of heavy workpieces such as castings and forgings.

Glass beads: have moderate hardness and smooth surface. They are often used for surface decontamination and smoothing of precision parts to reduce surface damage.

Steel shot: high strength, suitable for deep cleaning and enhancing surface hardness of metal surfaces. It is often used for rust removal and strengthening treatment in automobile manufacturing and shipbuilding industry.

Ceramic sand: high-temperature resistance, good chemical stability, suitable for surface treatment of special materials.

What Materials Are Suitable for Sandblasting?

Metals: Various metals and alloys, such as stainless steel, aluminum alloy, titanium alloy, alloy steel, copper, brass, etc.

Plastics: A variety of plastic materials, such as polycarbonate, polypropylene, nylon, acrylic, etc.

Composite materials: Composite materials such as carbon fiber can also be surface-treated by sandblasting.

Glass: Sandblasting technology can be used for glass surface treatment, but the appropriate sand materials and parameters need to be selected.

Wood: Sandblasting the wood surface can achieve a certain roughness and deburring effect.

What is the Surface Finish After Sandblasting?

The surface finish after sandblasting refers to the texture and quality of a material’s surface after it has been treated with an abrasive blasting process.

After sandblasting, the surface finish typically becomes rougher and matte in appearance. Sandblasting involves propelling abrasive particles at high speeds onto the surface, which removes contaminants, scales, and rust, while also creating a textured finish.

The Influence of the Main Parameters of Sandblasting On the Surface of the Workpiece.

The main parameters of sandblasting include sandblasting pressure, sand particle size, sandblasting distance and sandblasting angle. These parameters directly affect the treatment effect of the workpiece surface:

Sandblasting pressure: The greater the pressure, the stronger the impact of the sand particles and the better the cleaning effect, but too high a pressure may result in excessive roughness of the surface.

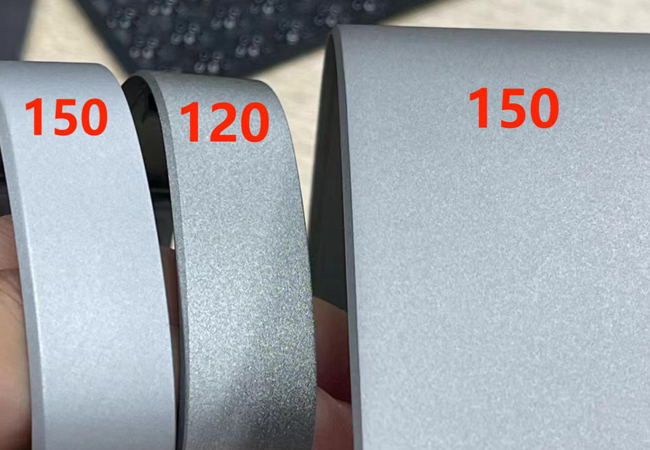

Sand particle size: The smaller the particle size, the finer the surface after treatment, which is suitable for precision processing; the larger the particle size, the more suitable for heavy-duty decontamination.

Sandblasting distance: If the distance is too close, it will easily cause surface damage; if the distance is too far, it will affect the cleaning efficiency.

Sandblasting angle: A suitable angle can evenly cover the surface of the workpiece and improve processing efficiency and quality.

How Much Does it Cost To Sandblast?

The cost of sandblasting can vary based on several factors, including the size of the project, the material being cleaned, and the location. Here’s a general breakdown:

Hourly Rate: Sandblasting services typically charge between $50 to $100 per hour. The time required will depend on the size of the area being treated.

Square Footage: On average, sandblasting costs around $1 to $3 per square foot for surface cleaning or preparation.

Project Size: For larger projects, like a full car or metal structure, prices can range from $500 to $2,000 or more.

Additional costs may apply for specialized coatings or environmentally friendly abrasives. Always get a quote based on the specifics of your project.

Note: The above fees are provided as a guide only and actual fees may vary depending on various factors.

Advantages of Sandblasting In CNC Machining.

Improve surface quality: By removing burrs, oxide layers, etc., the surface finish and flatness of the workpiece are improved, providing a good foundation for subsequent processing or assembly.

Enhance coating adhesion: The rough surface after sandblasting is beneficial to the adhesion of paints, coatings and other materials, extending the service life of the coating.

Reduce processing difficulty: For complex surfaces that are difficult to process directly through milling and turning, sandblasting can be used as an effective supplementary method.

Improve production efficiency: Automated sandblasting equipment can significantly reduce manual operations and improve processing efficiency and consistency.

What is Sandblasting Used For?

Pre-treatment of workpiece plating and bonding: Sandblasting can remove rust and other contaminants on the surface of the workpiece, and by replacing abrasives with different particle sizes, different levels of roughness can be achieved to improve the bonding strength between the workpiece and coatings and plating materials.

Light decoration effect: Sandblasting can polish the surface of various workpieces to make the surface of the workpiece more beautiful, smooth and non-reflective, and is suitable for surface treatment of special-purpose workpieces.

Automobile manufacturing: Sandblasting technology is widely used in the automobile manufacturing process to remove rust, paint and oxides from the body in preparation for repainting.

Ship manufacturing: In ship manufacturing, sandblasting technology is used to pretreat the surface of the hull to remove impurities such as rust, oil stains, and provide an ideal base surface for subsequent anti-corrosion coatings.

Aerospace: Sandblasting technology is used in the aerospace field for surface cleaning and treatment of parts to improve the fatigue strength and corrosion resistance of parts.

Electronics and electrical appliances: Sandblasting technology is used for surface cleaning and treatment of electronic components and electrical parts to improve surface quality and service life.

Architectural decoration: Sandblasting technology is used for surface treatment of glass, stone and wood to create unique surface effects and decorative effects.

In Conclusion

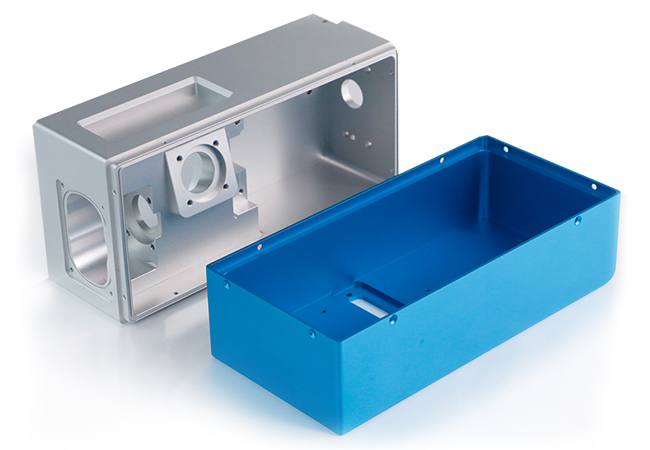

In CNC machining, sandblasting, as a supplementary method after milling, turning, and other processes, plays a key role in improving the surface quality of the workpiece, enhancing coating adhesion, reducing processing difficulty, and significantly boosting production efficiency. Our CNC sandblasting service is designed to provide the best possible surface finish, whether you are working with materials like cast iron or more complex alloys. With advanced sandblasting solutions, we ensure that each workpiece is treated to achieve optimal smoothness and durability.

VMT Offers Sandblasting Surface Finishing

VMT specializes in providing precision machining services, and we understand the critical role of surface treatment in the overall quality of the product. From prototype design to mass production, we are committed to helping customers create products with complex geometric structures and high aesthetics. With over 15,600 products treated with various sandblasting techniques, including sandblasting cast iron, we are dedicated to delivering stable, reliable product quality, on-time delivery, and an exceptional customer experience. Choosing VMT means choosing professionalism, efficiency, and trust in every aspect of the manufacturing process.

Frequently Asked Questions About Sandblasting

Shot Peening VS Sand Blasting: What’s the Difference?

Shot blasting and sandblasting are different in principle, application scope, treatment effect and equipment technology. Sandblasting uses high-speed airflow to spray abrasives such as sand particles to clean and roughen surfaces, while shotblasting strengthens metal surfaces through the impact of metal projectiles. Sandblasting is mostly used for surface cleaning, while shot blasting focuses more on surface strengthening. The surface after sandblasting is rough, while after shot peening it is relatively smooth and hardened.

How Does Sandblasting Compare With Other Treatments?

Sandblasting stands out among many surface pretreatment processes for its high efficiency, high quality, wide applicability and relatively low cost. It can quickly remove dirt, adjust surface roughness, is suitable for a variety of materials and shapes, and is an effective means of controlling production costs.

Can You Sandblast Wood?

Yes, you can sandblast wood. Sandblasting is often used to clean and prepare wood surfaces, remove old paint, or create textures. However, because wood is softer than metals or concrete, fine abrasive materials like baking soda or glass beads are used to avoid damaging the wood. The pressure and abrasive material need to be adjusted carefully to prevent gouging or excessive roughness.

How Does a Sandblaster Work?

A sandblaster uses compressed air to force abrasive materials (like sand, glass beads, or aluminum oxide) through a nozzle at high speed. The abrasive hits the surface, removing contaminants, paint, rust, or other debris. The pressure and type of abrasive are adjustable to suit different materials and surfaces. It’s often used for cleaning, etching, or surface preparation.