In CNC Machining manufacturing, poor surface durability and lackluster finishes can reduce the lifespan of precision parts. Customers expect components with perfect looks and robust performance. Metal plating offers a proven way to enhance both aesthetics and function.

Metal plating is the process of coating a metal surface with a thin layer of another metal to improve appearance, corrosion resistance, conductivity, or wear resistance. The process involves cleaning the base material, depositing the coating, and performing post-treatment to achieve the desired finish.

Let us explore in depth how plating metal works, the types available, the advantages and disadvantages, and why it is essential for precision CNC machining parts.

What Is Metal Plating?

Electroplating is a finishing process in which metal is deposited onto a surface, creating a thin coating on a metal substrate. This process, centuries old, remains essential to modern technology. This surface treatment offers numerous benefits, such as improving the appearance of CNC-machined parts, enhancing their corrosion resistance, and extending their service life. For manufacturers, it’s a critical step in ensuring high-quality, high-precision parts that meet customer specifications.

Step-by-Step Metal Plating Process for CNC Machining Parts

1. Surface Preparation

2. Pre-treatment

3. Plating

4. Post-treatment

5. Inspection

summary

| Step | Description | Key Purpose |

|---|---|---|

| Surface Preparation | The base material is meticulously cleaned, degreased, and polished to remove oils, dirt, and machining residues. | Creates an optimal surface profile for superior coating adhesion. |

| Pre-treatment | Oxide layers are removed and the surface is chemically activated. | Enhances molecular bonding between base material and coating for long-lasting performance. |

| Plating | The coating is applied using electroplating and metal finishers or advanced chemical deposition methods. | Achieves the required finish, coating thickness, and functional properties. |

| Post-treatment | The plated part is rinsed, dried, and sealed under controlled conditions. | Improves corrosion resistance, increases wear durability, and preserves appearance. |

| Inspection | Coating thickness and adhesion strength are measured, and the surface is checked for defects. | Ensures every CNC machined part meets strict tolerance and quality standards. |

Different Types of Metal Plating

Choosing the appropriate metal plating method depends on several factors, including the compatibility of the base material, the desired surface characteristics, and the specific application requirements. Below are the most common types of metal plating used in precision manufacturing and CNC machining industries:

-

Electroplating uses an electric current to deposit a uniform metal layer onto the surface of the part. This method is widely applied in automotive trim and electronic connectors due to its excellent adhesion and finish quality.

-

Electroless Plating relies on chemical reactions rather than electricity to evenly deposit metal coatings. It is especially useful for parts with complex geometries and high precision requirements, such as CNC machining parts.

-

Vacuum Deposition involves applying a thin metal film in a vacuum chamber, ensuring an ultra-clean and precise coating. This method is common in optical lenses and semiconductor manufacturing.

-

Hot-dip Plating entails immersing the part in molten metal, providing a thick, durable layer that offers excellent corrosion resistance. It is typically used for structural steel beams and corrosion-resistant fasteners.

-

Spray Coating applies atomized molten metal onto surfaces, ideal for large industrial machinery or repair work where uniform coverage over complex shapes is necessary.

Common Types of Metal Plating and Their Features

| Plating Method | Process Description | Typical Applications |

|---|---|---|

| Electroplating | Uses electric current to deposit a metal layer | Automotive trim, electronics connectors |

| Electroless Plating | Chemical reaction deposits metal evenly without electricity | Precision CNC parts, complex geometries |

| Vacuum Deposition | Deposits a thin metal film in a vacuum environment | Optical lenses, semiconductor components |

| Hot-dip Plating | Immerses parts in molten metal | Steel beams, corrosion-resistant fasteners |

| Spray Coating | Sprays atomized molten metal onto the surface |

Advantages and Disadvantages of Metal Plating

Choosing the right metal plating process is crucial for CNC machining manufacturers to meet performance and quality demands. Understanding the benefits and limitations of metal electroplating allows for informed decisions that balance cost, durability, and environmental impact.

| Advantages | Description | Disadvantages | Description |

|---|---|---|---|

| Enhanced corrosion resistance | Creates a protective metal layer that prevents rust and environmental damage, extending part lifespan. | Higher cost for precious metal coatings | Using metals like gold or platinum increases material and processing costs significantly. |

| Improved appearance for premium products | Produces smooth, shiny finishes that meet high aesthetic standards for electronics and automotive parts. | Potential environmental regulations | The process involves hazardous chemicals, requiring strict compliance with environmental laws. |

| Increased hardness and wear resistance | Hardens surfaces to resist abrasion and mechanical wear, crucial for CNC machined parts. | Requires careful waste management | Proper disposal of plating baths and wastes is mandatory to avoid contamination and penalties. |

| Better electrical conductivity for electronics | Ensures superior conductivity and solderability for connectors and circuit boards. | Additional production steps required | Adds complexity and time to manufacturing, potentially extending delivery lead times. |

| Extended lifespan of CNC machined components | Combines corrosion and wear protection to maintain accuracy and functionality over time. | Possible coating defects if not controlled | Poor process control can cause peeling, cracking, or uneven coatings, affecting quality. |

Applications of Metal Plating Across Industries

Electroplating and metal finishers are indispensable across a broad spectrum of industries, enabling both functional and aesthetic enhancements to CNC machined parts:

-

Automotive

Used for decorative trim pieces, engine components, and corrosion-resistant fasteners, metal plating ensures durability under harsh environmental conditions while providing attractive finishes. -

Medical

Surgical tools, implantable medical devices, and diagnostic instruments benefit from plating’s biocompatibility, corrosion resistance, and wear durability. Precision plating ensures patient safety and device longevity. -

Electronics

Connectors, printed circuit boards, and electronic enclosures use plated coatings to improve electrical conductivity, prevent oxidation, and enhance solderability for reliable device performance.

-

Optical

Plating on lenses, reflectors, and precision optical instruments provides reflective surfaces and protective layers that preserve accuracy and extend service life. -

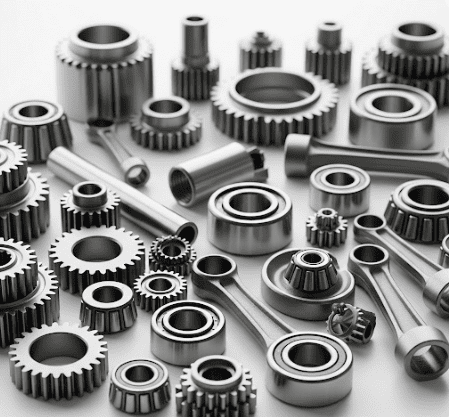

Industrial Machinery

Gears, bearings, hydraulic components, and other machinery parts rely on plating to reduce wear, prevent corrosion, and maintain tight tolerances in demanding operational environments.

In Conclusion

Metal plating significantly improves the durability, visual appeal, and performance of CNC machined parts across diverse industries. At VMT, advanced CNC technology, expert surface finishing, and rapid 24-hour turnaround ensure that every custom part achieves exceptional precision and a flawless finish.

High-quality metal plating surface treatments not only provide outstanding aesthetics but also deliver superior wear resistance, extended service life, and strong protection against corrosion. To achieve the best results, it is essential to clearly define your project requirements and choose the most suitable finishing solution.

Frequently Asked Questions About Metal Plating

What is the Difference Between Electroplating and Metal Plating?

Electroplating is a specific type of metal plating that uses electric current to deposit a metal layer onto a substrate. Metal plating is a broader term covering all methods of applying a metal coating, including electroplating, electroless plating, hot-dip plating, and more. Electroplating focuses on precise control of thickness and uniformity, while other plating methods may use chemical, thermal, or mechanical processes instead of electricity.

Is Metal Plating Expensive?

The cost of metal plating varies depending on the chosen method, metal type, coating thickness, and part complexity. Precious metals like gold or platinum are more expensive due to material cost. However, for many CNC machining applications, plating is cost-effective because it extends part lifespan, reduces maintenance, and enhances performance, which can save money in the long term.

What is the Purpose of Plating?

The main purposes of plating metal are to improve durability, prevent corrosion, enhance appearance, and provide specific functional properties such as electrical conductivity or wear resistance. In CNC machining parts, plating ensures components meet both functional and aesthetic requirements, making them suitable for demanding industries like automotive, electronics, medical, and aerospace.