What are the Benefits of Anodizing Aluminum?

Are you tired of your metal parts corroding, scratching or fading quickly? Standard surface finishes often fall short, leaving your products looking worn and unprofessional. Discover how anodized aluminum can provide the ultimate solution for increased durability and beauty.

Anodized aluminum electrochemically creates a protective oxide layer that creates a durable, corrosion-resistant and beautiful surface. The process significantly improves the material’s surface hardness, wear resistance and acceptance of a wide range of colors, making anodized aluminum ideal for many applications.

Let me take you deep into how this revolutionary process works and its benefits.

What Is Anodized Aluminum?

Anodizing aluminum is an electrochemical process that converts the metal surface into a durable, anodic oxide finish. To define anodized aluminum, it’s essentially a controlled oxidation process that forms a protective layer, rather than an applied coating. This means what does anodized mean is that the surface itself is transformed, not just covered. The result is a finish that’s more resistant to scratches, corrosion, and fading, while also allowing for vibrant, long-lasting colors.

How Does Anodizing Work?

The process starts by cleaning the aluminum part, then placing it in an acid solution with an electric current. This causes the surface to react with oxygen, forming a tough aluminum oxide layer. Finally, the part is sealed to protect it even further. This makes the surface harder, more durable, and ideal for both functional and decorative use.

What are the Benefits of Anodizing Aluminum?

The advantages of anodizing aluminum are numerous, making it a preferred choice for many high-performance CNC machining applications. This process enhances both the functional and aesthetic properties of aluminum parts.

1. Excellent Corrosion Resistance

Anodizing forms a dense oxide film on the surface of aluminum, which can effectively block the erosion of air, moisture, salt spray and chemicals, and prevent the metal from rusting or corroding.

It has stronger protection than ordinary spray painting or electroplating, especially suitable for parts used in seaside, outdoor, humid or acid-base environments, such as ship parts, outdoor equipment, architectural decorations, etc.

2. Improved Surface Hardness & Wear Resistance

The surface of anodized aluminum is harder than the original aluminum, which can effectively resist scratches, friction and wear in daily use.

This is very important for parts that are frequently touched or moved, such as mechanical transmission parts, consumer electronic housings, tools or sliding devices. The hardness of the anodic layer can reach a level similar to that of ceramics, greatly extending the service life.

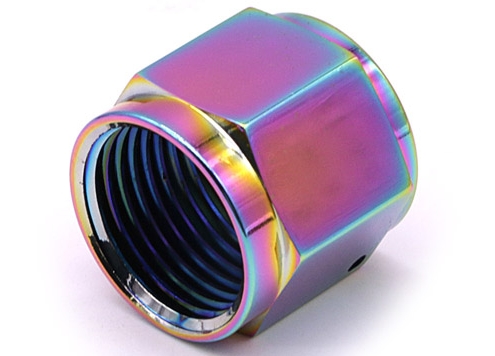

3. Long-Lasting, Vibrant Appearance

The anodized surface can achieve various colors by absorbing dyes. The color is integrated into the surface oxide layer and will not peel or fade as easily as paint.

The color is uniform and natural, and the metal texture is full, which is very suitable for products that need high appearance, such as mobile phone cases, laptop cases, audio cases or high-end home appliance appearance parts.

4. Electrical Insulation

The oxide layer is non-conductive and can be used in occasions where electrical isolation is required to prevent short circuit or electric shock risks.

Therefore, anodized aluminum is widely used in electronic equipment, radiators, electric control box housings, connectors and circuit protection structures.

5. Better Adhesion for Coatings

Before sealing treatment, the anodized aluminum surface has a microporous structure, which helps the adhesion of paint, printing ink or glue.

This makes anodized aluminum an ideal substrate for painting, multi-layer processing or laser engraving. For example, some products need to be anodized before silk-screening the logo or varnishing, which is more durable and not easy to fade.

Here is a summary of the Benefits of Anodizing Aluminum:

Frequently Asked Questions About Anodizing Aluminum

How Long Does Anodized Aluminum Last?

Anodized aluminum can last 20 years or more, depending on the environment and thickness of the oxide layer. In indoor or mild outdoor conditions, it remains durable and color-stable for decades. Thicker anodized layers (like Type III hard anodizing) offer longer-lasting protection, especially in harsh environments.

How to Remove Anodizing from Aluminum?

To remove anodizing, soak the part in a sodium hydroxide solution for a few minutes. The oxide layer will dissolve. Rinse thoroughly with water and neutralize with vinegar or citric acid. Always wear protective gear and follow safety guidelines when handling chemicals.

How to Polish Anodized Aluminum?

Polishing anodized aluminum requires a non-abrasive polish and a soft cloth. Use aluminum-safe metal polish (without harsh abrasives) and gently buff in circular motions. Avoid polishing through the oxide layer, anodizing is thin and can wear off if overdone.

Does Anodized Aluminum Rust?

No, anodized aluminum does not rust, because aluminum doesn’t contain iron. However, it can corrode in extreme conditions if the anodized layer is damaged or poorly sealed. The anodized coating actually helps protect the metal from corrosion and oxidation.

How to Anodize Aluminum Black?

To anodize aluminum black, follow the standard anodizing process (cleaning, etching, anodizing in sulfuric acid), then dip the part in black dye while the pores are still open. After dyeing, seal the surface in hot water or nickel acetate to lock in the color.