Can Sheet Metal Be Customized for Unique Designs?

Numerous industries face challenges in obtaining unique designs with conventional sheet metal, resulting in both functional and aesthetic constraints. Custom sheet metal offers a tailored solution that facilitates the creation of innovative designs.

Can sheet metal be customized for unique designs? Yes, sheet metal can be customized to achieve unique designs through the use of advanced fabrication techniques such as CNC machining, laser cutting, and various surface treatments.

Let’s explore how sheet metal customization works, its advantages, and its potential for unique designs.

What is a Sheet Metal Fabrication?

Sheet metal fabrication is the process of transforming flat metal sheets into custom metal pieces or structures using various techniques like cutting, bending, and assembling. This metal fabrication process is widely used to produce components for diverse industries. While standard sheet metal works focus on mass production, custom fabrication metal caters to specific client needs, offering tailored solutions for unique projects.

Custom metal & fabrication services, such as those provided by experienced companies like “VMT,” leverage modern technologies to enhance efficiency and quality. These services range from small-scale custom metal pieces to large-scale industrial solutions, meeting the demands of commercial and specialized applications.

What is Sheet Metal Customization?

Sheet metal customization involves modifying metal sheets to meet specific design, functional, or aesthetic requirements. This process adapts the material’s size, shape, thickness, and finishes to create highly specialized custom metal pieces for various industries.

Techniques like laser cutting, bending, punching, and surface treatments such as anodizing, powder coating, or painting are essential in custom fabrication metal. These methods allow manufacturers to produce intricate designs and ensure precision. Responsible metal fab practices focus on efficiency, waste reduction, and quality control, delivering products that align with client specifications across industries like automotive, electronics, and construction.

How is Sheet Metal Manufactured?

The sheet metal fabrication process involves several key steps, such as cutting, bending, welding, and assembling, to shape raw metal sheets into desired forms. Modern fabrication metal techniques incorporate advanced machinery like CNC laser cutters and precision bending machines to achieve high accuracy and quality.

Custom metal fabrication emphasizes precision and flexibility, enabling the production of both large-scale industrial components and bespoke custom metal pieces. For example, custom cut sheet metal is crafted with exact dimensions, ensuring it meets project-specific requirements. Steel fabrication services and other custom metal & fabrication methods offer solutions for both standard and specialized applications, making them invaluable to industries requiring reliable and tailored components.

How is Sheet Metal Customized for Unique Designs?

Sheet metal custom fabrication allows sheet metal components to attain intricate shapes and distinctive aesthetics while maintaining their structural strength. The entire process, which involves transforming raw, custom-sized sheet metal into tailored parts for diverse applications, encompasses a series of meticulously planned steps.

Each of these stages is pivotal in ensuring that the final product fulfills the design, functionality, and quality standards. By adhering to this structured methodology, the custom precision sheet metal parts provide dependable and premium-quality solutions across various industries. Whether you require custom-sized sheet metal or highly intricate metal components, professional expertise guarantees that the final product will align precisely with your unique design specifications.

1. Design and Planning

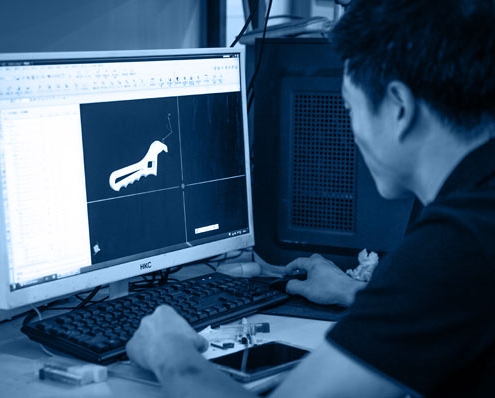

The journey begins with the design phase, where engineers from custom sheet metal fabricators who make custom parts collaborate with clients to create detailed CAD drawings. These designs outline every aspect of the custom sheet metal parts, ensuring they meet exact specifications. Refinement of dimensions, materials, and other critical features is crucial for achieving the desired balance of functionality and aesthetics.

2. Material Selection

Choosing the appropriate material is a cornerstone of the fabrication of sheet metal parts. Common choices include aluminum, steel, stainless steel, and copper, selected based on project needs. Strength, weight, corrosion resistance, and visual appeal are key factors influencing material selection. Proper material choice ensures the custom metal sheet delivers optimal performance in its application.

3. Cutting

High-precision tools such as laser cutters, water jets, or shears are used to custom cut fabrication of raw metal into desired shapes and sizes. These advanced machines are integral to custom sheet metal and sheet metal production, minimizing material waste while maintaining accuracy. This process prepares the custom metal components for subsequent stages of metal parts fabrication, ensuring that each piece meets exact specifications.

4. Custom Sheet Metal Forming

Forming shapes the custom metal sheet into its final structure using techniques such as bending, stamping, and rolling. CNC bending machines provide unparalleled precision and consistency, accommodating even the most intricate designs.

5. Joining and Assembly

Individual parts are joined to form the finished structure. Techniques like welding, riveting, or bolting are chosen based on the product’s functional requirements. Spot welding and seam welding are particularly effective for ensuring the strength and durability of the sheet metal components.

6. Surface Treatments

Surface treatments enhance both the appearance and functionality of the finished custom sheetmetal parts. Processes such as powder coating, anodizing, and polishing protect against corrosion and wear while delivering a professional finish. Treatments are tailored to align with the product’s operational demands and aesthetic goals.

7. Quality Inspection

Quality assurance ensures that the final custom metal components meet the original design specifications. Detailed inspections verify dimensions, appearance, and structural integrity, guaranteeing compliance with client and industry standards.

8. Delivery

After passing rigorous quality checks, the fabricated components are carefully packaged and shipped. Custom sheet metal fabricators that make custom parts provide accompanying documentation, such as technical manuals, to facilitate seamless integration. Timely delivery ensures client satisfaction and project continuity.

Choosing the Right Materials for Your Project

Selecting suitable materials is essential for ensuring both functionality and aesthetics in custom sheet metal projects. It is important to consider various factors such as durability, weight, corrosion resistance, and machinability when determining the appropriate materials for customization.

Aluminum

Aluminum is a lightweight and versatile metal known for its excellent corrosion resistance. Its low density makes it ideal for applications where weight reduction is crucial, such as in the aerospace and automotive industries. Aluminum naturally forms a protective oxide layer when exposed to air, enhancing its resistance to corrosion. This material also boasts good thermal and electrical conductivity, making it suitable for heat exchangers and electrical components. Additionally, aluminum is highly malleable and easy to work with, allowing for various manufacturing processes including extrusion, casting, and machining.

Stainless Steel

Stainless steel is renowned for its exceptional strength and durability, making it a popular choice in construction, industrial equipment, and household appliances. This alloy contains chromium, which forms a self-healing oxide layer, providing excellent resistance to corrosion and staining. Stainless steel maintains its mechanical properties across a wide range of temperatures, making it suitable for both cryogenic and high-temperature applications. Its aesthetic appeal, coupled with ease of cleaning and maintenance, makes it a preferred material in architectural and food processing industries. Stainless steel also offers good weldability and formability, allowing for versatile fabrication options.

Titanium

Titanium is a high-performance metal that combines strength with light weight, making it invaluable in aerospace, marine, and medical applications. It has an exceptional strength-to-weight ratio, surpassing many other metals. Titanium exhibits remarkable corrosion resistance, even in harsh environments such as seawater and chemical processing plants. Its biocompatibility makes it an excellent choice for medical implants and prosthetics. Titanium also maintains its properties at elevated temperatures, making it suitable for jet engine components and other high-temperature applications. While more expensive and challenging to process than some other metals, titanium’s unique combination of properties makes it indispensable in demanding environments where performance is critical.

What Are the Advantages of Custom Sheet Metal?

Customizing sheet metal provides a variety of advantages, such as increased design freedom, precise fit, and enhanced product functionality.

1. Tailored Solutions

Custom sheet metal fabrication offers unparalleled flexibility in creating tailored solutions that precisely meet unique design requirements. This level of customization enables manufacturers to produce parts with exact specifications, ensuring perfect fit within complex assemblies. It allows for application-specific designs tailored to industries such as aerospace, automotive, or medical equipment. The ability to customize often results in improved functionality, as each component can be optimized for its intended use. Furthermore, custom fabrication allows for the incorporation of specific design elements that contribute to the overall aesthetics of the final product, meeting both functional and visual requirements.

2. Reduced Material Waste

The customization process in sheet metal fabrication significantly contributes to reducing material waste, leading to more sustainable and cost-effective production. Custom designs allow for optimized nesting, enabling more efficient arrangement of parts on the sheet and maximizing material utilization. Advanced cutting technologies used in custom fabrication minimize material loss during the cutting process. Additionally, custom orders typically align closely with actual needs, reducing excess inventory and associated waste. The ability to easily sort and recycle scrap material from custom projects further enhances waste reduction efforts, contributing to a more environmentally friendly manufacturing process.

3. Compatibility with Advanced Engineering

Custom sheet metal fabrication is highly compatible with advanced engineering requirements, making it an invaluable resource for cutting-edge projects. It allows for the integration of complex features and intricate design elements that may be difficult or impossible to achieve with standard parts. Engineers can specify exact materials and grades to meet specific performance criteria, such as strength, weight, or corrosion resistance. The customization process facilitates rapid prototyping and design iterations, which are crucial for advanced engineering projects.

4. Increased Design Freedom

Custom sheet metal fabrication offers unprecedented design freedom, allowing engineers and designers to push the boundaries of what’s possible. It enables the creation of parts with complex geometries that may not be available in standard offerings. This ability to customize fosters the development of innovative solutions to engineering challenges. Custom parts can incorporate unique design elements that set products apart in the marketplace, contributing to brand differentiation.

5. Precise Fit and Assembly

Custom sheet metal parts ensure precise fit and assembly, leading to improved product quality and efficiency. Parts designed to fit perfectly can significantly reduce assembly time and associated labor costs. This precision minimizes gaps, misalignments, and potential points of failure in the final product, enhancing overall quality. Custom-designed parts can better distribute loads and stresses within an assembly, improving structural integrity. Additionally, well-fitted custom parts can simplify maintenance procedures by making disassembly and reassembly easier, reducing downtime and maintenance costs over the product’s lifecycle.

6. Enhanced Product Functionality

Custom sheet metal fabrication leads to enhanced product functionality, allowing for optimized performance in various applications. Parts can be designed to maximize their specific function within the overall product, improving efficiency and effectiveness. Custom designs can enhance various aspects of product performance, such as thermal management, weight reduction, or structural strength improvement. The ability to integrate multiple functions into a single custom part can replace several standard components, streamlining the product design and potentially reducing complexity. Furthermore, custom fabrication allows for the incorporation of user-specific features or ergonomic considerations, enhancing the product’s usability and appeal to end-users.

What are the Limitations of Custom Sheet Metal?

While customization is versatile, it has its own set of challenges, such as cost and material constraints.

1. High Initial Costs

Custom sheet metal fabrication often involves a significant upfront investment, primarily due to the need for specialized tooling and setup processes. For small-scale projects or businesses operating on tight budgets, these initial costs can be prohibitive. While the long-term benefits of customization may outweigh these expenses, the initial financial burden remains a notable limitation.

2. Material Limitations

Not all metals are compatible with custom sheet metal fabrication. Certain materials, such as those that are excessively brittle or soft, may not withstand the required processes like cutting, forming, or joining. This limitation narrows the range of materials that can be effectively used, potentially impacting the durability or functionality of the final product.

3. Complexity of Design

Highly intricate or complex designs often necessitate the use of advanced machinery, skilled labor, and additional tooling, all of which can increase both production time and cost. Moreover, certain complex designs may push the limits of what is feasible in manufacturing, leading to challenges in achieving precise tolerances or desired finishes.

4 . Production Lead Times

Customization inherently requires more time compared to standard production processes. Each step, from design and material selection to fabrication and inspection, demands careful attention to detail. This results in longer lead times, especially for projects involving unique designs, specialized treatments, or extensive quality checks.

How to Cut Aluminum Sheet Metal?

To cut aluminum sheet metal, you can use tools such as a hacksaw, circular saw with a metal blade, jigsaw, or shears depending on the thickness and the required precision. For cleaner cuts, consider a CNC plasma cutter or laser cutter. Ensure the metal is secured, and always use the correct cutting blade for aluminum to prevent binding or damage.

How to Cut Stainless Steel Sheet Metal?

Cutting stainless steel sheet metal requires more effort due to its hardness. You can use tools like metal shears, a hacksaw, or a high-quality circular saw with a carbide-tipped blade. For thicker sheets, a plasma cutter or laser cutter can offer precise cuts. Be sure to use the proper cooling methods (like lubricants) to prevent overheating and blade damage.

Common Applications of Custom Sheet Metal

Customized sheet metal plays a vital role across multiple industries, fulfilling diverse and specialized needs.

Automotive Industry

Custom sheet metal plays a crucial role in the automotive industry, where it is used to fabricate components such as body panels, engine parts, and chassis elements. The precision and durability of custom metal fabrication enhance both the structural integrity and aesthetic appeal of vehicles, ensuring safety and performance across a wide range of models and designs.

Aerospace Industry

In aerospace, custom sheet metal is indispensable for crafting high-performance parts like aircraft frames, fuselage panels, and engine components. Materials such as aluminum and titanium are used for their lightweight and strength properties.

Medical Equipment

Custom sheet metal is vital for creating precision-made medical equipment, including enclosures, brackets, and surgical instruments. These components must meet exacting tolerances and hygiene standards. Customization allows manufacturers to tailor equipment for specific medical applications, enhancing functionality and patient care.

Electronics

The electronics sector relies on customized sheet metal for protective casings, heat sinks, and other critical components. These parts safeguard sensitive electronic devices against environmental factors and mechanical damage while ensuring optimal thermal management, contributing to the reliability and performance of the technology.

Industrial Machinery

Sheet metal is integral to the manufacturing of conveyor systems, machine housings, and other industrial equipment components. Customization ensures these parts meet the specific operational and environmental demands of industrial processes, improving efficiency and durability in machinery applications.

Architectural Sheet Metal Fabrication

Custom sheet metal also plays a significant role in architectural design and construction. Architectural sheet metal fabrication involves the creation of unique and functional metal structures for buildings and other structures. Architectural sheeting, such as architectural metal sheets and architectural design sheets, can be used for exterior cladding, roofing, walls, partitions, and other elements. These custom-made metal parts and components can add aesthetic appeal, durability, and functionality to buildings, enhancing their overall design and performance. Unique architectural designs and finishes can be achieved through customization, meeting the specific needs and preferences of architects, designers, and building owners.

How to Choose the Right Sheet Metal Customization Provider?

Identifying a dependable service provider ensures that your project fulfills quality standards, adheres to budget constraints, and meets deadlines. Seek out custom sheet metal fabricators that make custom parts, equipped with cutting-edge technology, seasoned engineers, and extensive customization capabilities to guarantee precision and operational efficiency.

VMT is a reliable partner with advanced CNC machinery, highly skilled engineers with over 20 years of experience, and the ability to quote within 24 hours and produce custom simple sheet metal parts within 3 days. As one of the leading sheet metal fabricating Ltd providers, we excel in custom sheet metal fabrication services and offer comprehensive fabrication metal works for all your custom metal projects.

In Conclusion

Custom sheet metal opens endless possibilities for unique designs, functional improvements, and sustainable manufacturing solutions. Whether for aesthetics or functionality, customized sheet metal delivers tailored solutions across industries, meeting the highest quality standards.

Frequently Asked Questions

What Are Some Design Considerations in Sheet Metal Forming?

Design considerations in sheet metal forming include material selection, bend radius, and tolerances. Material choice affects strength, flexibility, and cost. Bend radius should be at least equal to the sheet thickness to avoid cracking. Additionally, accounting for factors like springback, hole placement, and part geometry ensures accurate and efficient manufacturing while reducing errors.

Which Software is Used for Sheet Metal Design?

Several CAD software programs are widely used for sheet metal design, including SolidWorks, AutoCAD, and CATIA. These tools allow designers to create 3D models, simulate bends, and analyze stress points in the design. Specific sheet metal features in these programs enable flattening, generating part layouts, and testing manufacturability before production begins.

What Can Vary in Sheet Metal Forming?

Several factors can vary in sheet metal forming, including material properties, thickness, and forming techniques. Different materials, such as steel or aluminum, require adjustments in tooling and pressure. Variations in thickness affect flexibility and strength, while forming techniques like bending, stamping, or drawing influence the process, cost, and final product characteristics.

How to do Staking in Sheet Metal?

Staking in sheet metal is a process where a raised protrusion or bump is created on the surface of the metal to secure two pieces together or create a permanent fastening point. The process typically involves using a staking tool or a hydraulic press to form the raised section. This technique is often used in automotive and electronic enclosures to avoid additional fasteners or welding.

How to Flatten out Humped Sheet Metal?

To flatten out humped sheet metal, you can use a manual or hydraulic press to apply even pressure and straighten the metal. Another method is to use a hammer and anvil or a planishing tool to carefully tap and smooth out the hump. Always ensure the sheet is secured properly and use light, controlled pressure to avoid causing additional deformation.

What Size Circular Saw is Needed for Sheet Metal Cutting?

For cutting sheet metal, a 7-1/4 inch circular saw is commonly used with a metal-cutting blade. For thicker metal, you might need a 10-inch saw or even a specialized circular saw designed for metal, which typically uses a carbide-tipped blade. Always ensure the saw’s RPM matches the requirements for cutting metal, and use proper safety equipment like gloves and goggles.