Plastic 3D printing is a manufacturing process that involves the creation of three-dimensional objects from plastic materials using additive technology. Here are the key aspects of the plastic 3D printing method:

1. Digital Model Creation

The first step in plastic 3D printing involves creating a digital 3D model of the desired object. This can be accomplished using CAD (Computer-Aided Design) software or by downloading a pre-existing model from online repositories.

2. Slicing

Once the digital model is ready, it is sliced into thin, horizontal layers using slicing software. This software generates a series of instructions known as G-code, which directs the 3D printer on how to construct the object layer by layer.

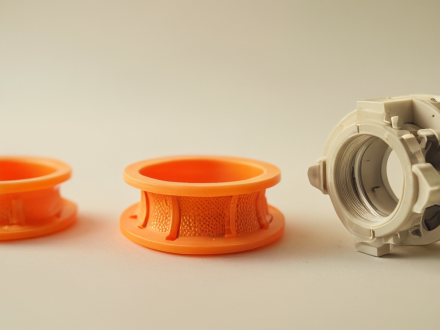

3. Printing Process

- Material Extrusion: The most common plastic 3D printing method is Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF). In this method, a plastic filament is heated to its melting point and extruded through a nozzle. The nozzle moves in a predetermined pattern, depositing the melted plastic onto the build plate to form each layer.

- Other Methods: There are alternative plastic 3D printing techniques, such as Stereolithography (SLA) and Digital Light Processing (DLP). These methods utilize a laser or projector to cure liquid plastic resin, creating solid layers.

4. Layer-by-Layer Construction

The printer constructs the object by depositing and solidifying the plastic material layer by layer, following the detailed instructions from the G-code. This layering process continues until the entire object is completed.

5. Post-Processing

After the printing process concludes, the printed object may require several post-processing steps to achieve the desired finish. This can include removing support structures, sanding to smooth out surfaces, and applying paint or other finishes to enhance aesthetics or functionality.

![]()

![]()

![]()

![]()

![]()