How Much Does It Cost to CNC Machining Aluminum Parts?

CNC machining is an invaluable process for producing high-precision aluminum parts. Whether you’re manufacturing components for automotive, aerospace, or electronics, CNC machining technology offers endless possibilities for the manufacture of aluminum products. However, many customers often ask the question – how much does it cost to CNC machine aluminum parts?

This question is always a focus of customers. This article will take a deep look at the cost structure of CNC machining aluminum parts and analyze the key factors that affect the price to help you better understand how much this service will cost.

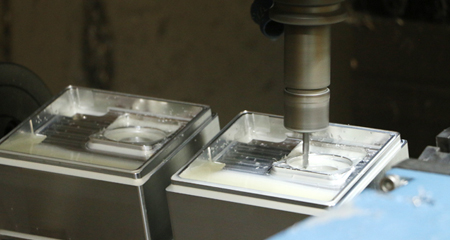

Learn About CNC Machining of Aluminum Parts.

CNC machining of aluminum parts refers to the use of a pre-programmed computer numerical control system to control the relative movement of the tool and workpiece on the machine tool to perform cutting, drilling, turning, milling and other machining operations on aluminum alloy materials. During the machining, the machine tool’s tool cuts the aluminum alloy material according to the predetermined trajectory and parameters, and finally obtains the required parts or products.

Cost to CNC Machining Aluminum Parts

The total cost to CNC machine aluminum parts typically ranges from $30 to $500 per part, depending on factors like part complexity, material type, tolerance requirements, and order quantity. Each stage of production affects the final price, and complexity plays a major role in determining the total expense.

Setup Expenses:

Initial preparations, encompassing tool setup, fixture arrangement, and programming, can vary from 200 per hour, contingent upon the level of complexity involved.

Machining Charges:

The hourly rate for machining aluminum parts typically falls between 150. The intricacy and detail of the part directly influence the machining duration and, consequently, the cost.

Material Expenses:

Aluminum prices are subject to fluctuation but generally hover between 6 per pound. High-performance alloys, such as 7075-T6, may incur substantially higher costs.

Illustration:

For a straightforward 6061 aluminum bracket, the overall cost could lie within a range of 100 per part, dependent on the quantity and complexity of the order.

Advantages of CNC Machining Aluminum Parts.

CNC machining offers a wide range of benefits when it comes to manufacturing aluminum components. From precision and speed to flexibility and complexity handling, it provides a reliable and efficient solution for modern production needs. Below is a table summarizing the key advantages of CNC machining aluminum parts:

| Advantage | Description |

|---|---|

| High Precision | CNC machines use advanced control systems to produce aluminum parts with tight tolerances, ensuring accuracy in complex shapes and fine dimensions. |

| High Efficiency | Automated and continuous operation reduces production time, shortens lead times, and increases output without sacrificing quality. |

| High Flexibility | CNC systems allow quick changes in programming, making it easy to adapt to different designs or tasks using the same equipment. |

| Compact Part Machining | CNC machining can handle intricate features like deep cavities, thin walls, and non-standard shapes that traditional methods struggle to achieve. |

| Consistency and Repeatability | Once programmed, CNC machines can produce large batches of identical parts with minimal variation, ideal for high-volume manufacturing. |

| Material Compatibility | Aluminum is well-suited for CNC machining due to its softness, light weight, and excellent machinability, allowing for faster cutting speeds. |

Factors Affecting the Price of CNC Machined Aluminum Parts.

The pricing of CNC machined aluminum parts is influenced by a multitude of factors that work in concert to determine the final cost. Here’s a comprehensive overview of these key factors:

Material Cost:

The type of aluminum alloy chosen directly impacts the basic cost. Popular alloys like 6061-T6 are lightweight, durable, corrosion-resistant, and highly machinable, making them cost-effective for general manufacturing. On the other hand, 7075-T6, known for its high strength-to-weight ratio, is more expensive and harder to machine, thus increasing production costs. Market supply and demand also fluctuate the prices of these alloys. Additionally, material loss during the machining process, such as cutting waste and deburring, adds to the final material cost.

Machining Complexity and Programming Costs:

The complexity of the part design is a significant determinant of machining costs. Intricate geometric shapes, fine dimensional requirements, and special machining features like deep hole machining and complex surface milling require specialized tools and longer machining times, pushing up the overall costs. Programming such complex designs is challenging and time-consuming. High-performance tools, although costly upfront, can reduce tool replacement frequency and lower long-term costs due to their efficiency.

Machining Accuracy:

High-precision machining necessitates advanced machine tools, cutting tools, and testing technology, all of which increase the machining costs. Stringent quality standards require additional quality inspection steps and advanced testing equipment, further elevating the final product cost.

Quantity and Batch Size:

The number of parts required and the batch size play a crucial role in pricing. Large batch production amortizes fixed costs like programming and equipment commissioning, reducing the unit cost per part. Conversely, small batches or customized parts often have higher unit prices due to increased setup time and flexibility requirements.

Machining Time:

The labor-hour pricing method, based on machining time and unit time cost, is another pricing strategy. Machining time is influenced by design complexity, the number of features on the part, and required machining accuracy. More complex designs and higher accuracy demands lead to longer machining times, thus increasing costs. Hourly operating costs, including labor, equipment depreciation, and energy consumption, vary among factories.

Post-Machining Costs:

Post-machining processes such as surface treatment (anodizing, sandblasting, polishing) and quality inspection add to the final cost. Surface treatments enhance aesthetics, corrosion resistance, or functionality but come at an additional expense. Rigorous quality inspection processes ensure product quality but also reflect in the final cost.

How to Effectively Reduce the Cost of CNC Machining Aluminum Parts?

Reducing CNC machining costs doesn’t mean sacrificing quality. With the right strategies, businesses can lower expenses while maintaining or even improving product performance. The following key methods can help cut costs effectively during the aluminum CNC machining process:

Optimize design: Reduce machining difficulty and material loss by simplifying the design, reducing unnecessary machining features and optimizing material usage.

Bulk purchasing and production planning: centralized procurement of materials to obtain more favorable prices; rational planning of production batches to reduce changeover time and improve equipment utilization.

Choose the right service provider: comprehensively compare the quotations, service capabilities, equipment levels and industry reputation of different service providers to choose the most suitable partner.

Improve machining efficiency: Advanced CNC machining technology and equipment can be actively introduced. These advanced technologies and equipment can not only significantly improve machining accuracy and ensure the excellence of product quality, but also greatly shorten the processing cycle, thereby improving overall production efficiency.

What is the Price of CNC Machine Tools?

When considering the cost of CNC machining aluminum parts, it is crucial to have a solid understanding of the initial investment in a CNC machine.

Machine type and features: There are many types of CNC machines, including milling machines, lathes, plasma cutters, etc., and each type has its own specific price range. The price of a basic CNC milling machine may range from £15,000 to £40,000, while the price of a high-end, multi-functional model can climb to more than £150,000. In addition, the machine’s features and specifications are also key factors in determining the price. For example, 5-axis CNC machines are usually more expensive than 3-axis machines due to their greater flexibility and precision.

Size and Capacity: The size and processing capacity of a machine directly affects its price. Large CNC machines designed for large-scale industrial production will naturally cost more than smaller machines suitable for small businesses or hobbyists.

Configuration and options: The configuration and additional options of the CNC machine also affect its final price. The brand and performance differences of core components such as the CNC system, servo motor, and drive, as well as optional accessories such as an automatic tool changer and cooling system will increase the total cost of the machine.

In Conclusion

CNC aluminum parts are complex and are affected by multiple factors such as design complexity, material type, production quantity, machining time, and surface treatment requirements. In order to optimize the cost structure, accelerate production efficiency and ensure product quality, we focus on refined design, implement batch material procurement strategies, and continuously improve machining efficiency to form a comprehensive cost and quality management plan. By deeply understanding these key factors and flexibly applying cost optimization strategies, we can ensure that we can provide customers with high-quality CNC aluminum parts at a very competitive price.

Get Pricing for Your CNC Machined Aluminum Parts.

Want to get an accurate quote for CNC aluminum parts machining? Contact us now. At VMT, we leverage over 15 years of experience in CNC machining and provide custom solutions tailored to your needs. You only need to upload the 3D CAD file and our professional team will provide you with a detailed quote within two hours. At the same time, we also provide free DFM analysis to help you optimize product design and ensure machining efficiency and quality. Looking forward to your consultation.

Frequently Asked Questions About CNC Machine Aluminum Parts

Comparison of CNC Machining and 3D Printing Costs.

CNC machining and 3D printing have their own characteristics in terms of cost. CNC machining usually has a higher initial investment and is suitable for large-scale, high-precision production. Cost-effectiveness is achieved by optimizing the production process. Material cost and labor cost are the key. 3D printing, on the other hand, has a relatively low initial investment and is suitable for small batches and rapid prototyping. Material and design costs are the main considerations. Although the cost per piece may be higher, it can quickly respond to market demand and shorten the product development cycle. Which method to choose depends on specific needs and production scale.

Is CNC Machining Suitable for Mass Production of Aluminum Parts?

CNC machining is suitable for large-scale production of aluminum parts because it has the advantages of high precision, high efficiency, flexibility and repeatability. It can ensure the stability of the production process and the consistency of product quality, effectively reduce labor costs and meet the needs of large-scale production.

What Are the Common Surface Finish Options for CNC Machined Aluminum Parts?

Common surface treatment options for CNC machined aluminum parts include anodizing, spraying, sandblasting, polishing, electroplating, and oxidation coloring. The specific choice depends on the purpose and performance requirements of the aluminum parts.

What is the Cheapest Aluminum for CNC Machining?

Aluminum 6061 is the most cost-effective and versatile alloy for CNC machining, balancing strength, machinability, and cost.

What is the Typical CNC Machining Time for Aluminum Parts?

Machining time depends on part complexity, but simple parts can take a few hours, while more complex parts might take several days.