VMT’s blog aim to share our hard earned knowledge on manufacturing and product development. We hope these articles help you to optimize your product design and better understand the world of rapid prototyping, rapid tooling, 3D printing and low-volume manufacturing.

A Comprehensive Guide to Aluminum Extrusion

What is Aluminum Extrusion?

Aluminum extrusion is a plastic machining method that applies high pressure to the aluminum billet in the mold cavity (or extrusion barrel) to cause directional plastic deformation of the aluminum billet. Thus, parts or semi-finished products with required cross-sectional shape, size and certain mechanical properties are extruded from the die hole of the mold. This process utilizes the powerful power of hydraulic pressure, combined with high-hardness molds, to produce a variety of profiles ranging from simple box-shaped sections to complex frame members or electric radiators. After the final product is cut to length, it can also be customized according to needs. Carry out subsequent processing such as drilling, tapping, and anodizing.

What are The Characteristics of Aluminum Extrusion Products?

Aluminum extruded products have the characteristics of low density but high strength, corrosion resistance, excellent thermal conductivity, flexible processing and beautiful surface.

Not only can it significantly reduce weight and energy consumption while maintaining structural strength. It can also maintain stable performance in various environments, especially in the fields of cooling and heat exchange. In addition, aluminum extruded products are easy to process into various complex shapes and sizes to meet diverse needs.

Common Aluminum Grades are Used In Extrusion.

In the aluminum extrusion process, commonly used aluminum grades include but are not limited to the following:

- 6061 aluminum alloy: It has good processability, corrosion resistance and medium strength. It is one of the commonly used aluminum materials in the extrusion process.

- 6063 aluminum alloy: has excellent surface quality and corrosion resistance and is often used in highly decorative areas such as building doors, windows, and curtain walls.

- 6082 Aluminum Alloy: Fairly strong, suitable for simple cross-section extrusions, and can be anodized. It is widely used in load-bearing structures of ships, buildings and transport structures.

- 7075 aluminum alloy: high-strength aluminum alloy. Although extrusion is difficult, it is used in high-demand fields such as aerospace and aerospace because of its excellent mechanical properties.

Aluminum Extrusion Process.

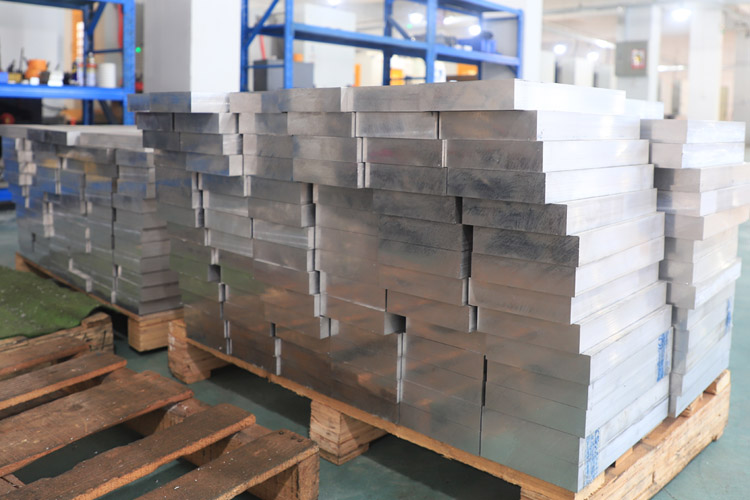

Raw Material Preparation

Selection: Choose the appropriate aluminum alloy type and aluminum ingots of different compositions (such as 6061, 6063, etc.) according to product requirements.

Inspection: Strictly inspect the aluminum alloy billet to ensure that its size, shape and surface quality meet the requirements.

Mold Preparation

The mold is designed and manufactured according to the required shape and size of the extruded aluminum profile. The accuracy and quality of the mold directly affect the forming effect of the extruded product.

Heating Treatment

Heating the blank: Heating the blank to a certain temperature (usually 400-500 degrees Celsius) to improve its plasticity and fluidity for subsequent extrusion molding. The heating method can be gas furnace, electric furnace or induction heating.

Preheat the mold: Preheat the mold to the appropriate temperature (usually 450-500 degrees Celsius) to reduce thermal stress during the extrusion process, improve mold life and the quality of extruded products.

Extrusion Process

Extruder preparation: Install the mold on the extruder and debug it. The mold design should match the final product shape.

Loading: Put the heated billet into the feeding barrel of the extruder, and feed the billet into the mold mechanically or hydraulically.

Extrusion: Start the extruder, apply pressure (generally between a few hundred tons to thousands of tons), push the aluminum ingot through the die to form the required profile. The extrusion process compresses and shapes the aluminum.

Cooling And Solidification

Cooling: Extruded aluminum profiles are often immediately water-cooled to fix their shape and improve mechanical properties.

Cutting: According to the length requirements, use cutting equipment (such as saws, knives) to cut the cooled aluminum profiles into the required size.

Post-Processing Process

Aging treatment: High-temperature aging treatment is performed on some aluminum alloys to enhance the strength and hardness of the material.

Surface treatment:

Anodizing: Improves corrosion resistance and aesthetics.

Spraying or electroplating: Provides different surface effects and protection.

Quality Inspection

Dimensional inspection: detect the outer dimensions and tolerances of aluminum profiles.

Performance testing: Analyze physical and chemical properties to ensure that design requirements are met.

What Shapes Can Aluminum Extrusion Be Extruded Into?

Aluminum extrusion processing can produce aluminum products of various shapes and specifications, including but not limited to:

Simple tubes, rods and wires-this is one of the most basic applications of aluminum extrusion technology.

Complex solid and hollow profiles: such as aluminum profiles with complex cross-sections, which are widely used in construction, automotive, aerospace and other fields.

Variable cross-section profile: that is, the cross-section of the profile changes in stages or gradually along the length direction. This kind of profile has unique advantages in special application scenarios.

What Factors Affect The Quality And Characteristics Of Extruded Aluminum?

Raw material characteristics: The chemical composition, microstructure and original state of aluminum will affect its extrusion performance and the quality of the final product.

Process parameters: including extrusion temperature, extrusion speed, extrusion ratio, etc. The setting of these parameters requires comprehensive consideration of material characteristics and production requirements.

Mold design and condition: The shape, dimensional accuracy, material selection and wear of the mold have an important impact on the cross-sectional shape, dimensional consistency and surface finish of the extruded aluminum.

What is The Cost of Aluminum Extrusion?

The cost of aluminum extrusion depends on several factors, including aluminum material cost, equipment cost, labor cost, and other related expenses. Aluminum Extrusion Aluminum can be more expensive to produce and process than some other metal materials.

Generally speaking, the cost of aluminum accounts for the largest part in the extrusion manufacturing process, and its price fluctuates greatly due to market supply and demand and market influences.

Our VMT has free basic optimization and in-depth manufacturing optimization. At the same time, it can effectively reduce additional costs caused by defective products, production interruptions, etc. by improving yield, reducing production abnormalities, and responding quickly to abnormalities.

What are the Advantages And Applications Of Aluminum Extrusion?

Advantage:

Improve material utilization: The extrusion process can produce parts with complex shapes and reduce material waste.

Improve material properties: The structure and properties of the material are optimized during the extrusion process, improving the strength and corrosion resistance of the product.

High production efficiency: The extrusion process can achieve continuous production and improve production efficiency.

High flexibility: Production plans and product specifications can be flexibly adjusted according to market demand.

Application:

Aluminum extrusion products are widely used in construction, transportation, electronics, mechanical equipment and other fields.

In the construction field, aluminum extruded profiles are used for decorative components such as doors, windows, and curtain walls.

In the field of transportation, aluminum extruded products are used as lightweight components for vehicles such as cars, trains, and airplanes.

In the electronics field, aluminum extrusions are used in the manufacture of radiators, casings and other products.

In Conclusion

In short, aluminum extrusion is an important metal processing method. It applies external force to the metal blank placed in the extrusion barrel to make it flow out of a specific die hole, thereby obtaining an aluminum profile with the required cross-sectional shape and size. . This method is widely used in many fields such as construction, transportation, electronics, machinery, etc.

VMT’s Aluminum Extrusion Services

VMT offers multi-length aluminum profiles and complex geometric designs, combined with comprehensive manufacturing services to ensure designs are flexible and cost-effective. By choosing VMT as your aluminum extrusion process partner, you can get one-on-one engineering support. Our senior engineers will work closely with you to provide structural design optimization suggestions and 100% assist you in choosing the most appropriate extrusion process to meet your production and processing needs.