VMT’s blog aims to share our practical experience and knowledge accumulated during the manufacturing and product development process. Our goal is to use these articles to help you improve product design and increase your understanding of CNC machining, 3D printing, rapid prototyping, low-volume manufacturing, and surface treatment technologies. The information we provide is designed to provide actionable guidance and insights for your CNC machining projects.

Study Guide: CNC Milling vs CNC Drilling

CNC milling and CNC drilling are key technologies in CNC machining, each with its own unique machining characteristics and scope of application. Understanding their differences can not only help optimize the machining process, but also effectively improve product machining quality and market competitiveness. This guide will elaborate on the characteristics of these two technologies, their differences, and their respective application scenarios.

What is CNC Milling?

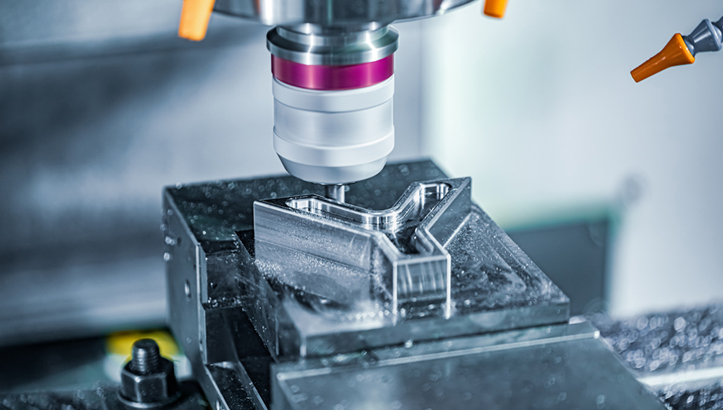

CNC milling is an efficient automated processing technology. It uses precise programming software to control the machine tool, realize the precise movement of the tool along the preset trajectory, and gradually remove the workpiece material by combining spindle rotation and tool feed to produce parts with complex geometry and high precision. This process not only improves the processing accuracy to the micron level, but also significantly improves production efficiency by reducing manual operations, and flexibly adapts to a variety of materials and processing requirements.

What is CNC Drilling?

CNC drilling is a CNC processing technology that combines high precision, high efficiency and flexibility. It uses advanced CNC systems and servo drive technology to accurately control the movement of machine tools, allowing the drill to automatically move along a preset trajectory to complete precise drilling operations on the workpiece. At the same time, CNC drilling can be flexibly programmed according to different processing requirements and is suitable for processing workpieces of various shapes, sizes and materials. This technology can not only process holes of various diameters and depths at micron-level precision, but also significantly improve production efficiency and reduce manual intervention.

Differences Between CNC Milling and CNC Drilling.

CNC milling and CNC drilling are two widely used technologies in the field of CNC machining. There are many differences between them. The following is a detailed explanation of the differences between the two technologies:

CNC Milling vs CNC Drilling: Working Principle

CNC milling achieves material removal by combining the rotary motion of the tool and the linear motion of the workpiece. During the machining process, the feed direction of the tool can be at any angle to the tool axis, which enables CNC milling to process a variety of complex shapes. CNC drilling, on the other hand, drills holes by forcing a drill to rotate around its axis against the workpiece. During the machining process, the feed direction of the drill is always axial, that is, machining is performed along the depth direction of the workpiece.

CNC Milling vs CNC Drilling: Cutting Speed and Feed Rate

CNC milling shows higher cutting speed and feed rate when machining complex shapes and removing large amounts of material, and its efficiency is remarkable. However, CNC drilling focuses on hole machining, and its cutting speed and feed rate are relatively low to ensure machining accuracy and surface quality.

CNC Milling vs CNC Drilling: Surface Quality

CNC milling can generate a smoother and more uniform machined surface by precisely controlling the tool motion trajectory and cutting parameters, and the surface quality is better than that of CNC drilling. Although CNC drilling can also meet certain surface quality requirements, it may be inferior in some aspects.

CNC Milling vs CNC Drilling: Tools and Machine Tools

CNC milling uses a variety of tools, such as flat milling cutters, face milling cutters, etc. These tools realize multi-axis motion on CNC milling machines to complete complex processing tasks. CNC drilling mainly relies on drill bits. Although there are many types of drill bits, their processing methods are relatively simple and mainly proceed in the vertical direction.

CNC Milling vs CNC Drilling: Cost and Delivery Time

Both CNC milling and CNC drilling are cost-effective, but CNC milling is slightly more expensive due to the complexity of the process and the variety of materials. In terms of lead time, CNC drilling projects are usually shorter because their processing tasks are more straightforward, while CNC milling may take longer due to the complexity of the process.

Advantages and Disadvantages of CNC Milling

CNC milling is a widely used precision machining method capable of producing complex components with high accuracy and efficiency. However, while it offers many operational and production advantages, it also presents some limitations depending on the materials being machined and the complexity of programming. Here is an overview of the main advantages and disadvantages of CNC milling:

| Category | Description |

|---|---|

| Advantages | |

| High precision | CNC milling enables highly accurate machining by controlling tool paths and cutting parameters. It can achieve micron-level accuracy suitable for demanding applications. |

| High efficiency | CNC milling machines combine the functions of milling, drilling, and boring, reducing manual intervention and improving throughput through process integration. |

| High automation | CNC milling automates most processes, reducing reliance on operator skill and ensuring consistent quality. It can be integrated into production lines for continuous operation and lower labor costs. |

| Disadvantages | |

| Material limitations | Although CNC milling handles many materials, it struggles with hard-to-machine alloys like titanium or heat-resistant metals. These cause rapid tool wear and increase production costs. |

| Programming and debugging time | Complex parts require detailed programming and testing. Time is spent analyzing designs, writing CNC codes, and adjusting machine operations, which can delay urgent or high-volume production. |

Advantages and Disadvantages of CNC Drilling

CNC drilling is widely used in modern manufacturing due to its precision, efficiency, and automation. However, like any machining method, it comes with both strengths and limitations. The table below summarizes the key advantages and disadvantages of CNC drilling to help you better understand its practical applications and constraints.

| Category | Description |

|---|---|

| Advantages | |

| High efficiency | CNC drilling automates the drilling process, enabling faster completion of multiple holes with high precision. This reduces manual effort, lowers error rates, and cuts production costs. |

| Strong adaptability | CNC drilling systems can accommodate parts of varying shapes and sizes. By modifying the program, different hole types and specifications can be processed easily. |

| Simple operation | The interface and controls of CNC drilling machines are user-friendly. Operators with basic training in machine tools and programming can begin using the system quickly. |

| Versatility | CNC drilling is capable of more than basic drilling. It can also handle complex features such as angled holes, spiral holes, and other intricate cutting paths required in manufacturing. |

| Disadvantages | |

| Sensitive to environment | Harsh conditions such as vibration, dust, or unstable power supply can negatively affect CNC performance. These issues may cause signal interference or system failures. |

| Limited specialization | While flexible, CNC drilling may not be suitable for some niche applications. Specialized machines or controllers may be required for certain tasks, making general-purpose CNC systems less effective in those cases. |

Application of CNC milling and CNC drilling

Application of CNC Milling

Mechanical manufacturing: CNC milling is widely used in the field of mechanical manufacturing and can process parts of various complex shapes, such as gears, bearing seats, couplings, etc.

Aerospace: In the field of aerospace, CNC milling technology is used to process high-precision and high-demand parts such as aircraft engine parts, aircraft structural parts, and spacecraft structural parts.

Automobile manufacturing: CNC milling machines can process key components such as automobile engine parts, automobile chassis parts, and automobile body parts.

Electronic Manufacturing: In the electronics manufacturing industry, CNC milling technology is used to process electronic parts such as circuit boards, heat sinks, connectors, etc. These parts have extremely high requirements for precision and surface quality, and CNC milling technology can meet these requirements and ensure the stability and reliability of the products.

Medical devices: CNC milling technology is also used in the manufacture of medical devices, such as surgical instruments, prostheses, orthotics, etc. These parts have extremely high requirements for precision and materials, and CNC milling technology can achieve high-precision processing.

Application of CNC Drilling

Automobile manufacturing: In the automobile manufacturing process, CNC drilling technology is used to process holes on various parts. These holes are crucial for the assembly and connection of parts, and CNC drilling technology can achieve high-precision and high-efficiency drilling processing.

Mold manufacturing: In the field of mold manufacturing, CNC drilling technology is used to process cooling holes, exhaust holes, etc. on molds. CNC drilling technology can ensure the precision and position accuracy of the holes.

Aerospace: In the aerospace field, CNC drilling technology is used to process various precision holes on aircraft and spacecraft. These holes are crucial to the structural strength and performance of aircraft and spacecraft, and CNC drilling technology can achieve high-precision and high-efficiency processing.

Electronics: In the manufacture of electronic products, CNC drilling technology is used to process holes on circuit boards. These holes are used to connect circuit components and wiring, and have a significant impact on the performance and reliability of the circuit board.

In Conclusion

As two indispensable processing technologies in modern manufacturing, CNC milling and CNC drilling each show their unique value and advantages. Milling is very suitable for processing complex shapes, while drilling is good at processing precise holes.

When choosing CNC milling and drilling, consider project requirements, material properties, and budget. Balance precision, efficiency, and cost to optimize production and improve product quality.

Start Your Metal CNC Milling or CNC Drilling Manufacturing Production.

Choose VMT as your metal CNC milling and drilling partner, we will provide you with professional engineering consulting services. Our team of professional engineers will work side by side with you to carefully analyze and optimize your product structure design to ensure that every machining step is accurate and efficient. We focus on practicality and tailor the most suitable processing solution according to your specific needs.

Frequently Asked Questions About CNC Milling and CNC Drilling

What is the Difference Between CNC Milling and CNC Machining?

CNC milling is an important part of CNC machining. There are certain differences between the two in terms of machining scope, implementation method, machining object and degree of automation. CNC machining uses different CNC machine tools to achieve different machining tasks. For example, CNC lathes are mainly used for machining rotating parts, while CNC grinders are used for grinding high-precision surfaces. CNC milling is mainly achieved through CNC milling machines, which use milling cutters to cut on the workpiece, remove excess material, and form the required shape and size.

Why is Milling Better than Turning?

Milling does have some advantages over turning in some aspects, such as machining flexibility, processing efficiency, tool life and machining accuracy. However, when choosing a processing method, it is also necessary to comprehensively consider factors such as specific machining requirements, material properties, equipment conditions and economy. In some cases, turning may be a more appropriate choice.

Do CNC Drill Banks Lose Accuracy?

Yes, CNC drill banks can lose accuracy over time due to mechanical wear, thermal expansion, vibration, or poor maintenance. Factors like worn spindles, backlash in axes, or contamination can reduce precision. Regular calibration, maintenance, and using high-quality tooling can help maintain accuracy.

Do CNC Routers Drill Holes?

Yes, CNC routers can drill holes, especially in wood, plastic, and soft metals. While primarily designed for routing or cutting shapes, they can be equipped with drill bits and programmed to perform hole drilling operations efficiently.

How does a CNC Drilling Machine Work?

A CNC drilling machine operates by following programmed instructions to position the drill bit and control feed rate and depth. The system automatically moves the drill to specified coordinates and executes precise hole drilling with minimal human intervention.