Surface finish symbols represent standardized instructions on technical drawings, guiding machinists on how smooth or rough a finished surface must be. Correctly reading these symbols ensures parts meet functional, aesthetic, and quality standards while reducing manufacturing errors.

Medical CNC machining involves using computer-controlled tools to manufacture complex, high-tolerance parts used in the healthcare industry. From surgical instruments to implantable devices, it guarantees consistent accuracy and finish.

With 100+ machines, including high precision CNC milling machines, VMT delivers custom parts as fast as within 3 days. Our engineers provide free design support to optimize manufacturing efficiency and visual appeal.

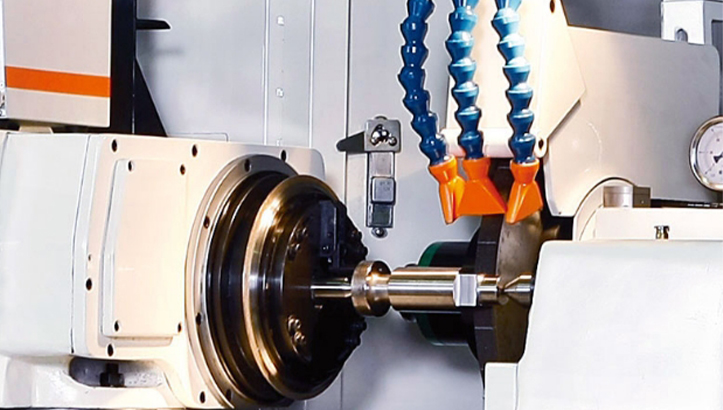

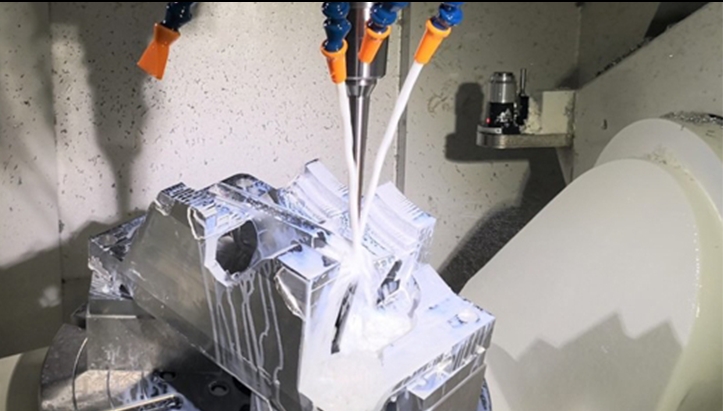

At VMT, we utilize over 100 machines, including 4-axis CNC, 5-axis CNC mills, and advanced CNC milling machines. We handle tolerances up to 0.01 mm, with capabilities across aluminum, stainless steel, copper, and engineering plastics. All machines operate under ISO 9001 and IATF 16949 standards.

From aerospace to medical implants, Titanium is one of the most versatile metals used in modern engineering. At VMT, we specialize in titanium machining with a focus on quality, speed, and consistency.

British engineers and manufacturers call it aluminium, while Americans stick with aluminum. This spelling discrepancy isn’t just a matter of dialect. It is also a reflection of the metal’s history, its naming evolution, and regional language standards.

Yes, stainless steel can be anodized, but the process is more complex than anodizing aluminum. The key challenge lies in creating a thicker and more visible oxide layer. Stainless steel anodizing is often used for specific applications where the appearance and performance of the material need to be enhanced.

Grinding machines include surface grinders, cylindrical grinders, centerless grinders, tool and cutter grinders, and more. Each type offers unique capabilities for machining precision parts. Knowing the different types of grinders and how they work helps you select the right equipment for your specific project needs.

NC and CNC machines are essential in modern manufacturing, improving accuracy and efficiency. NC machines follow pre-set instructions, while CNC machines use computer programming for greater flexibility and automation. Knowing their differences helps industries select the best technology for their needs.

CNC machining is essential to aerospace manufacturing, providing the precision, reliability, and compliance required by industry standards.

VMT offers advanced capabilities for aerospace parts, utilizing high-end milling machines, 5-axis CNC machining, and precision grinding to produce components with exceptional accuracy.