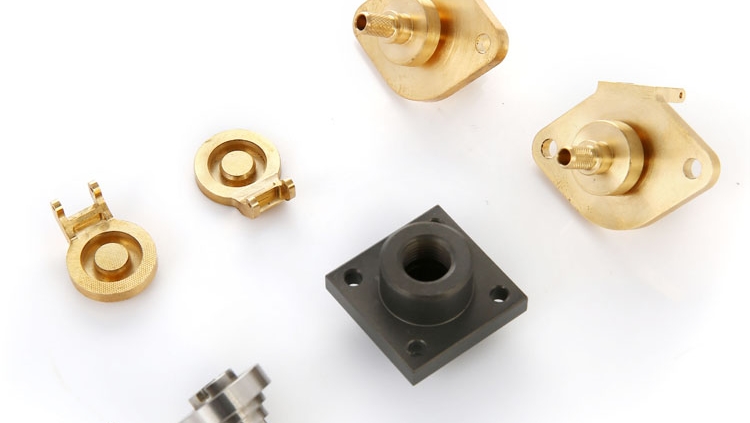

When it comes to manufacturing, billet machining, casting, and forging each offer distinct advantages. Billet machining ensures high precision, casting is cost-effective for large volumes, and forging is known for creating highly durable parts that can withstand extreme conditions.

Aluminum does not rust in the same way that iron does, thanks to its unique properties. However, aluminum is still susceptible to corrosion, especially when exposed to harsh environments like saltwater or high humidity. Understanding corrosion and taking preventive measures can help maintain the integrity of your aluminum parts for years.

Tolerance in press fit involves allowable deviations in the dimensions of mating parts to ensure reliable assembly. Achieving the right tolerance is essential for mechanical connections without compromising the integrity of the assembly.

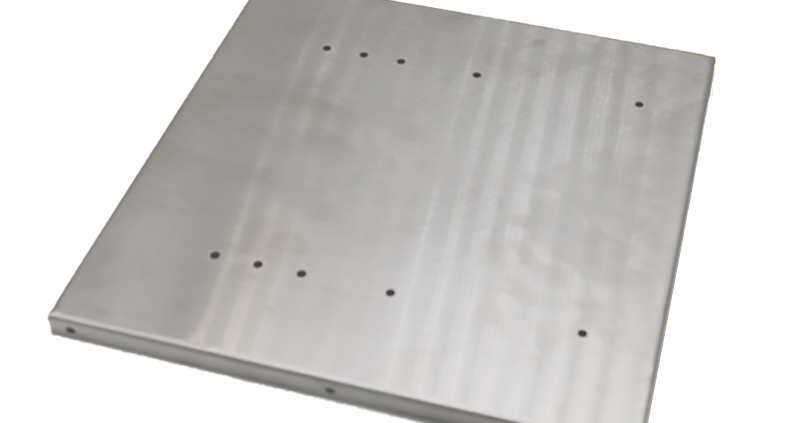

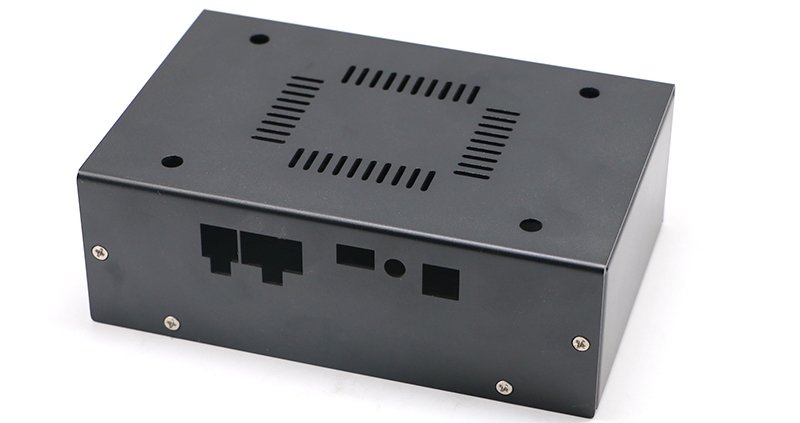

Sheet metal is a thin, flat form of metal used in countless industries to manufacture components, structures, and parts. It is one of the basic forms used in metalworking and can be cut and bent into a variety of different shapes. Sheet metal comes in a variety of thicknesses and materials, and its manufacturing process plays an important role in producing high-precision components.

Choose 4140 steel for strength and durability in tough tasks, or 7075 billet aluminum for lightweight projects. Note that billet aluminum, even high-strength 7075, typically doesn’t match forged steel’s strength. Choosing between 7075 billet aluminum vs 4140 steel depends on your needs for weight, strength, and corrosion resistance.

To find a reliable CNC machining manufacturer, consider their experience, certifications, technology, and customer reviews. A trustworthy partner will meet your quality standards, deliver on time, and offer excellent communication. This guide covers the essential factors to help you choose a CNC manufacturer that aligns with your project’s needs.

Curious about copper’s melting point? Copper melts at 1,085°C (1,984°F). This high melting point makes it ideal for electrical wiring and heat-resistant applications. Keep reading to explore copper’s properties and uses.

CNC machining and 3D printing each have distinct advantages. CNC provides high precision and material versatility for mass production, while 3D printing offers greater design freedom and quick prototyping. Understanding their strengths and applications will help you choose the right process for your part.

Brass and bronze are both metal alloys, but they differ in their composition and properties. Brass is primarily made of copper and zinc, while bronze is composed of copper and tin. These differences affect their appearance, strength, and resistance to corrosion.

Sheet metal fabrication processes are capable of producing highly accurate, durable, and economical parts. It is an important manufacturing method in industries such as automotive, aerospace, and medical devices. By gaining a deeper understanding of its various applications, you can make an informed decision and select the right manufacturing company to meet your specific requirements.