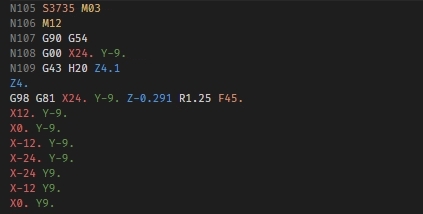

G-Code is a programming language used to control CNC machines. It gives instructions to CNC machines on how to move along specified paths in three-dimensional space, determining the speed, position, and depth of cuts.

While nylon is a type of polyamide, their performance in CNC machining can differ significantly. Both materials have excellent mechanical properties, but nylon offers better elasticity, while polyamide materials such as PA66 provide superior strength and durability. Understanding these differences is key when selecting the best material for high-precision machined components.

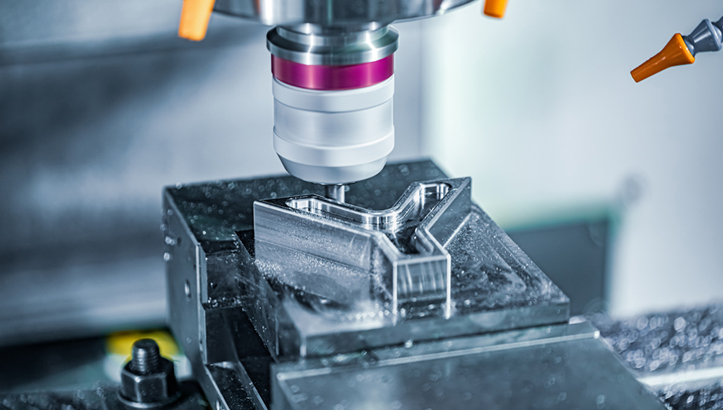

CNC Machining Plastic refers to a specialized tooling and machinery system designed to produce high-performancePlastic components with exceptional precision and quality.

Slot milling is a CNC process used to create precise slots and grooves in a variety of materials. It involves using slot milling tools and techniques to achieve the desired slot size and quality. Whether you need slot cutter milling or slotting tools, this guide will provide you with all the information you need to optimize your slot milling process.

Side Milling uses specialized cutters to shape edges and contour surfaces with exceptional accuracy, ideal for metals, plastics, and composites. Optimize your production with side milling for flat surfaces, slots, and complex geometries with tight tolerances.

End milling is a critical process in CNC machining that involves using a rotating tool to cut into the workpiece, creating precision shapes and components. This versatile method can handle complex cuts, ensuring high-quality finishes and precise measurements.

Form milling is a specialized machining process that uses custom-designed cutters to create precise and complex profiles on materials. By leveraging CNC machines and advanced form cutters, this method ensures efficient production of intricate shapes with tight tolerances.

7075 aluminum is one of the strongest aluminum alloys available, with a tensile strength of 7075 aluminum that can rival certain steels. However, is steel harder than aluminum? Generally, steel offers greater hardness and wear resistance.

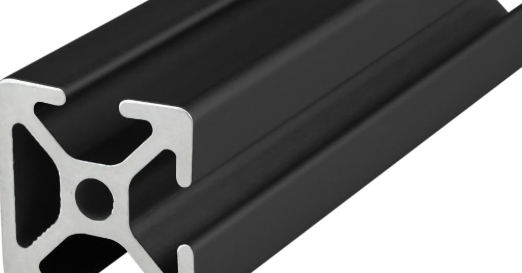

To anodize aluminum black, follow four key steps: pre-treatment, anodization, blackening, and sealing. Pre-treatment cleans the surface, ensuring better adhesion. Anodization forms a protective oxide layer. Blackening adds the color, while sealing enhances durability and resistance. By controlling factors like voltage, acid concentration, and sealing methods, a durable, appealing black finish is ensured.

The melting point of aluminum is 660.3°C (1220.5°F). Knowing this temperature helps avoid overheating, which can deform aluminum during machining, and ensures that the correct tools, feeds, and cooling systems are used.