British engineers and manufacturers call it aluminium, while Americans stick with aluminum. This spelling discrepancy isn’t just a matter of dialect. It is also a reflection of the metal’s history, its naming evolution, and regional language standards.

Yes, stainless steel can be anodized, but the process is more complex than anodizing aluminum. The key challenge lies in creating a thicker and more visible oxide layer. Stainless steel anodizing is often used for specific applications where the appearance and performance of the material need to be enhanced.

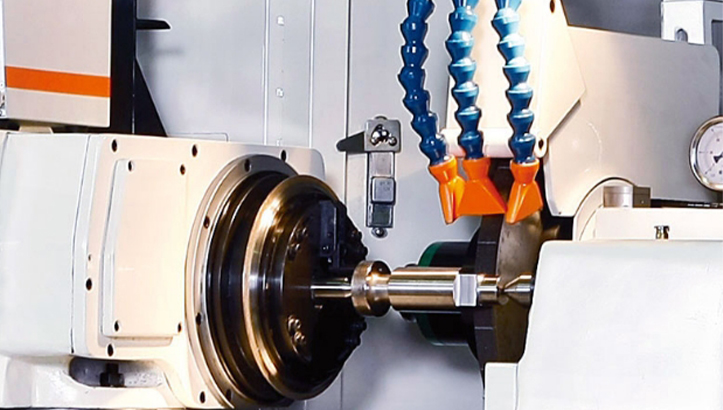

Grinding machines include surface grinders, cylindrical grinders, centerless grinders, tool and cutter grinders, and more. Each type offers unique capabilities for machining precision parts. Knowing the different types of grinders and how they work helps you select the right equipment for your specific project needs.

NC and CNC machines are essential in modern manufacturing, improving accuracy and efficiency. NC machines follow pre-set instructions, while CNC machines use computer programming for greater flexibility and automation. Knowing their differences helps industries select the best technology for their needs.

CNC machining is essential to aerospace manufacturing, providing the precision, reliability, and compliance required by industry standards.

VMT offers advanced capabilities for aerospace parts, utilizing high-end milling machines, 5-axis CNC machining, and precision grinding to produce components with exceptional accuracy.

CNC machining is a versatile and essential skill in modern manufacturing, but its complexity can vary depending on individual experience and the depth of knowledge required.

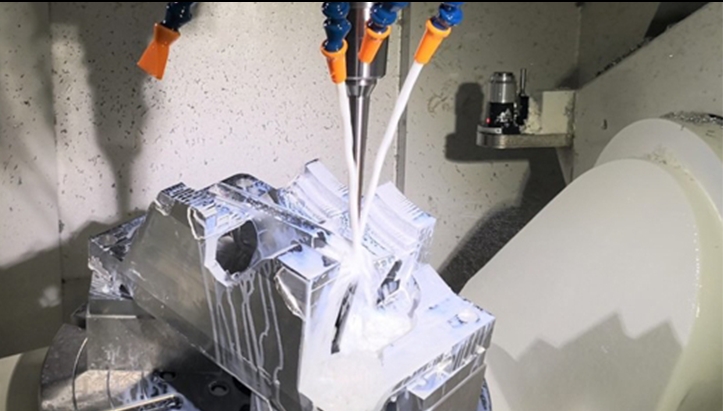

CNC machining is a precise manufacturing process that uses computer-controlled machines to cut, shape, and drill materials based on digital designs. It offers high precision, repeatability, material versatility, and scalability for both prototypes and mass production.

VMT specializes in high-quality machine prototyping and rapid prototype machining, utilizing advanced CNC technology to deliver precise and efficient results. Our expert engineers work closely with clients to provide customized solutions, ensuring fast turnaround times and prototypes that meet the highest standards for functionality and performance.

Swiss machining is a precision manufacturing process that utilizes specialized CNC machines designed to create extremely precise and complex parts. This technology is particularly known for its ability to manufacture small, intricate components that require high tolerance and fine detail.

Screws and holes play a critical role in automotive engineering, affecting assembly strength, durability, and safety. Selecting the correct screw and hole combination ensures optimal fastening, minimizes wear, and enhances structural integrity in high-performance applications.