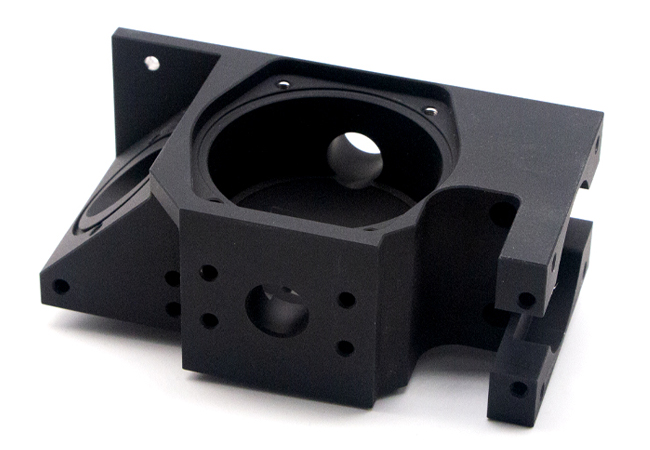

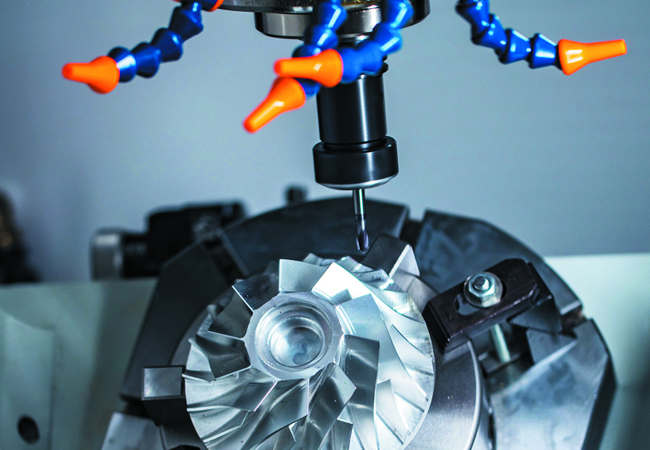

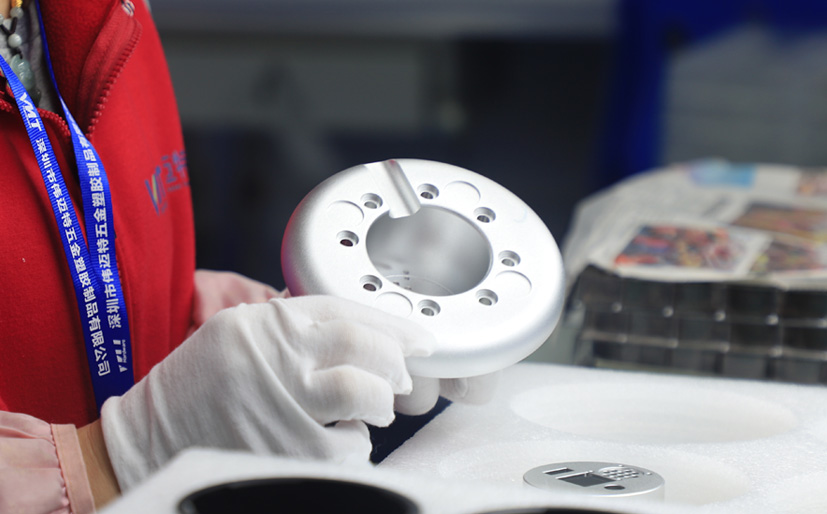

A poorly finished surface doesn’t just look unrefined, it can also affect the part’s durability, make cleaning more difficult, and even compromise structural integrity over time.

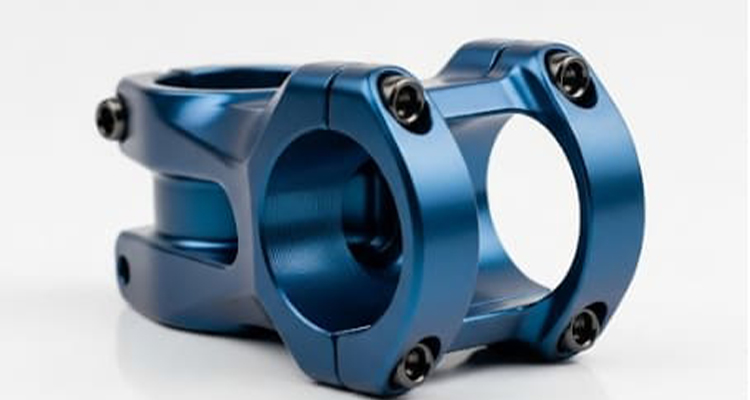

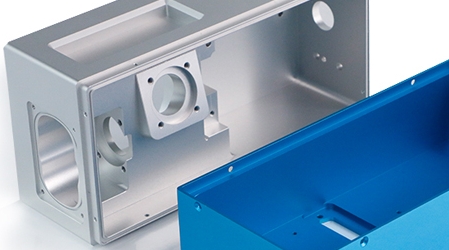

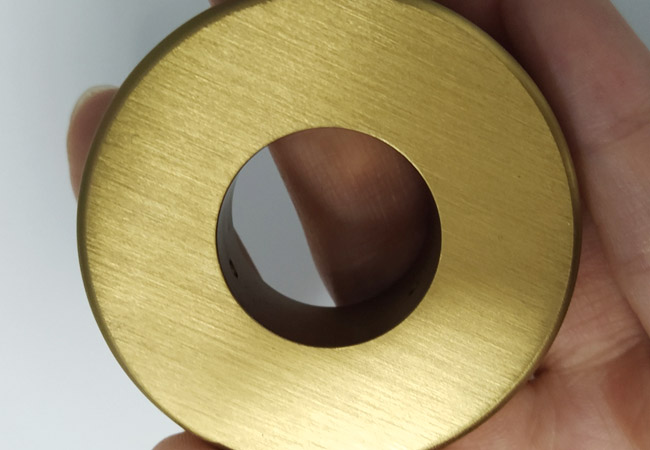

That’s why we provide a wide range of high-quality surface finishing options for our custom CNC mountain bike stems. Options include anodizing, polishing, and bead blasting, each designed to deliver a clean, smooth, and corrosion-resistant finish.

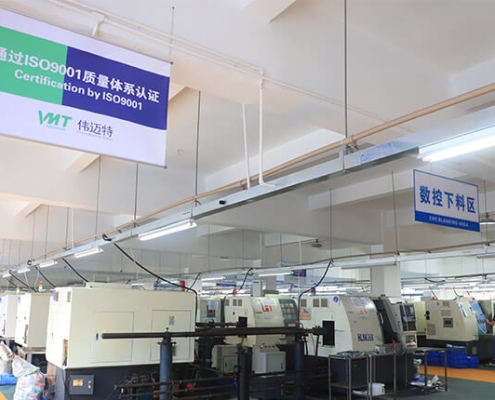

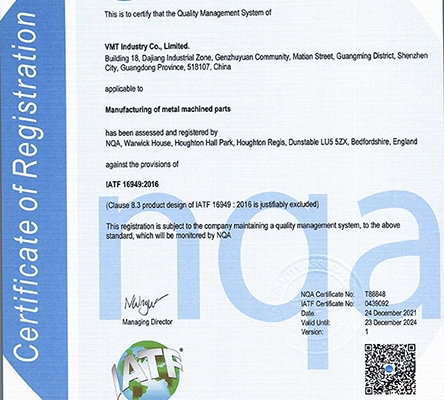

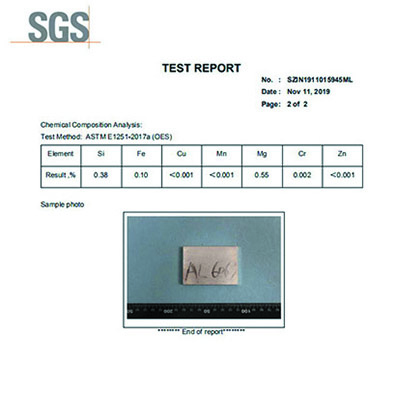

Backed by over 15 years of experience in precision part customization, we’ve built a strong, integrated supply chain that allows us to support complex manufacturing processes and diverse material combinations. Today, we offer over 40 customizable surface treatments, helping you achieve the exact look and performance finish your project demands.