VMT’s blogs aim to share our practical experience and knowledge accumulated during the manufacturing and product development process. Our goal is to use these articles to help you improve product design and increase your understanding of CNC machining, 3D printing, rapid prototyping, low-volume manufacturing, and surface treatment technologies. The information we provide is designed to provide actionable guidance and insights for your CNC machining projects.

Feed Rate and Cutting Speed: The Difference in CNC Machining

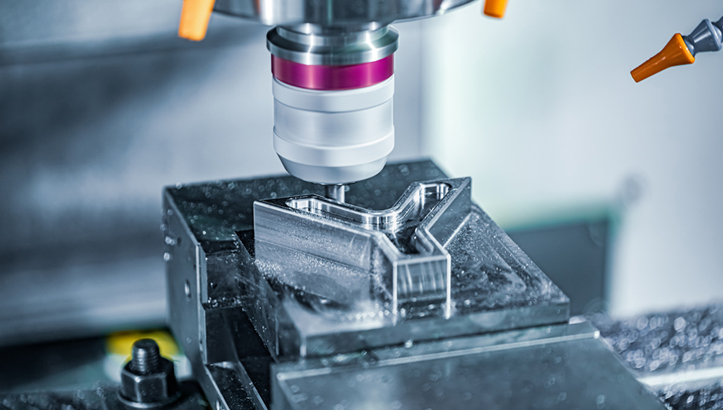

In CNC machining, feed rate and cutting speed are two core parameters that have a direct and significant impact on the final quality, accuracy, surface finish, machining efficiency and tool durability of the product. Understanding how these parameters are affected by various factors and determining the best machining parameters are essential for optimizing the production process. This article will take you to understand the differences in speed and feed in CNC machining operations.

What is the Feed Rate?

In CNC machining, feed rate is a variable that specifically indicates the distance the tool moves per unit of time (such as per minute) in a direction perpendicular to the spindle axis. For milling operations, the feed rate determines the depth of the tool’s penetration into the material per revolution (i.e., the feed per tooth); in turn, it directly affects the surface finish and machining efficiency of the workpiece. Correctly setting the feed rate can optimize the material removal rate while ensuring machining quality.

Considerations for Cutting Speed In CNC Machining.

Material adaptability: The choice of cutting speed should be adapted to the physical and chemical properties of the workpiece material. Different materials have different cutting speed ranges and need to be adjusted according to the hardness, toughness and other characteristics of the material.

Tool durability: Too high a cutting speed may cause tool overheating and increased wear, thus affecting tool durability and processing quality. Therefore, when selecting the cutting speed, factors such as the tool material and coating need to be considered.

Machining efficiency and precision: Cutting speed directly affects processing efficiency, but too high a cutting speed may reduce processing precision. Therefore, it is necessary to increase the cutting speed as much as possible to improve processing efficiency while ensuring processing precision.

Machine tool performance: The rigidity and drive capacity of the machine tool will also limit the choice of cutting speed. When selecting the cutting speed, it is necessary to ensure that the machine tool can stably operate under high-speed cutting conditions.

What is Cutting Speed?

Cutting speed refers to the linear speed at which the cutting edge of the tool moves relative to the workpiece surface. It is an important indicator for evaluating the speed of interaction between the tool and the workpiece during the cutting process. In milling and turning, cutting speed directly affects the generation of cutting heat, the magnitude of cutting force and tool wear. Reasonable control of cutting speed is crucial to prevent tool overheating, reduce wear and improve processing efficiency.

Precautions for CNC Machining Feed Speed.

Machining quality: Feed speed directly affects the roughness and precision of the machined surface. A lower feed speed can achieve better surface quality, but will reduce processing efficiency; a higher feed speed can improve processing efficiency, but may increase surface roughness.

Tool wear: Too fast a feed rate may increase the tool cutting load and cutting heat, thereby accelerating tool wear. Therefore, when selecting the feed rate, it is necessary to weigh the relationship between processing efficiency and tool durability.

Machine tool performance: The rigidity and feed drive capability of the machine tool will also limit the choice of feed speed. Too high a feed speed may cause the machine tool to vibrate more, affecting machining accuracy and stability.

Difference Between Feed Rate and Cutting Speed.

The main difference: Feed rate refers to the linear distance the tool moves per revolution or per minute on the workpiece (usually expressed in mm/rev or mm/min, recorded as s or f), which measures the speed of the tool through the workpiece material. Cutting speed, on the other hand, refers to the speed at which the tool cutting edge moves relative to the workpiece surface (usually expressed in m/min or ft/min, recorded as Vc), which reflects the actual speed of the tool cutting operation.

Impact on machining performance: Cutting speed directly affects the cutting force and power consumption during the cutting process, because higher cutting speed means more material is removed per unit time, thereby increasing the cutting load. In contrast, although feed rate also affects material removal rate, its direct impact on cutting force and power consumption is smaller.

Chip and temperature control: Cutting speed has a significant impact on cutting temperature. The higher the speed, the more cutting heat is generated, which may lead to increased tool wear and workpiece deformation. The feed rate has a relatively small impact on cutting temperature. It affects the stability of the machining process more by changing the generation and discharge of chips.

Surface quality: Feed rate directly affects the roughness and formation of scallop marks on the machined surface. High feed rate will lead to more ridge marks and increase surface roughness; while cutting speed has no direct correlation with the formation of these marks, so it does not affect the surface finish of the part.

Geometry and path: From a geometric point of view, cutting speed can be regarded as the “generatrix” that creates the surface shape of the workpiece, which determines the main direction of the tool cutting path. The feed rate is equivalent to the “directrix” along which these generatrixes move along the surface of the workpiece, which determines the specific movement trajectory of the tool on the workpiece.

Why Are Speed and Feed Important In CNC Machining?

In machining, speed and feed are important for the following reasons:

Machining Efficiency:

Cutting speed is directly related to the amount of material cut by the tool per unit time, and is a direct means to increase processing speed. A reasonable cutting speed setting can significantly shorten the production cycle, thereby improving overall processing efficiency.

On the other hand, the feed rate determines the distance the tool moves on the workpiece per unit time, which affects the rate of material removal. Under the premise of ensuring that the machining quality is not affected, using a higher feed rate can further accelerate the material removal process, thereby further improving machining efficiency.

Machining Quality:

When the cutting speed is too high, it will accelerate the generation of cutting heat and tool wear, which may cause deformation of the workpiece, thereby damaging the machining accuracy and surface finish. On the contrary, although the cutting speed is too low, it can reduce these risks, but it will reduce processing efficiency and increase costs. The selection of feed rate should also be cautious. Low feed rate can improve surface quality, but it will reduce efficiency; a high feed rate can improve efficiency, but it may increase surface roughness due to increased cutting force, affecting accuracy.

Tool Durability:

The reasonable matching of cutting speed and feed rate is very important to extend the service life of the tool. Too high cutting speed and feed rate will cause the tool to bear excessive cutting load and cutting heat, thus accelerating tool wear and damage.

Machine Tool Performance:

The rigidity and drive capacity of the machine tool limit the selection range of cutting speed and feed rate. Excessively high cutting speed and feed rate may cause the machine tool to vibrate more, affecting the processing accuracy and stability.

How to Determine Feed Rate and Cutting Speed?

Analyzed Workpiece Material:

Understand the physical and chemical properties of the workpiece material, including hardness, toughness, thermal conductivity, etc., to provide a basis for the selection of cutting speed and feed rate.

Select Tool:

Choose the right tool type and material based on the workpiece material and processing requirements. Tool geometry, material, and coating will affect the choice of cutting speed and feed rate.

Reference Empirical Formula Or Database:

Use the industry’s empirical formula or query the material processing database to obtain preliminary recommended values for cutting speed and feed rate. These recommended values are usually based on a large amount of experimental data and experience, and have certain reference values.

Test Cutting Verification:

Before formal machining, a trial cutting test is conducted to observe the machining effect (such as surface quality, cutting force, vibration, etc.) by adjusting the cutting speed and feed rate to determine the best parameter combination. During the trial cutting process, the cutting speed and feed rate can be fine-tuned according to the actual situation to achieve the best processing effect.

Dynamic Adjustment:

The cutting speed and feed rate are dynamically adjusted during the machining process based on real-time feedback such as cutting force, vibration, temperature, etc. This helps ensure the stability and efficiency of the machining process while avoiding problems such as tool damage and workpiece deformation.

In Conclusion

In CNC machining, precise control of cutting speed and feed rate is the key to optimizing machining performance. The proper combination of these two parameters is essential to improving the production efficiency of CNC machined parts. Therefore, engineers and machinists must have a deep understanding of the difference between cutting speed and feed rate in order to make appropriate adjustments in actual operations.

VMT focuses on providing a full range of one-stop precision machining solutions, covering every aspect from prototype design, CNC machining to surface treatment. We focus on helping customers realize complex geometric structure designs, and pay attention to the combination of product aesthetics and functionality.

Frequently Asked Questions About Feed Rate and Cutting Speed

How to Calculate Speed and Feed Rate for Drilling Operation on Lathe?

When drilling on a lathe, the calculation of cutting speed and feed rate is crucial. Cutting speed (Vc) is the speed at which the cutting edge of the tool moves relative to the workpiece surface, and the calculation formula is: Vc = π × DC × n/1000, where DC is the drill diameter (mm) and n is the spindle speed (rpm). For example, for a 12mm diameter drill and a spindle speed of 1350rpm, the cutting speed is about 50.9m/min.

The feed rate (vf) is the distance the tool moves on the workpiece per unit time. The calculation formula is: vf=fr×n, where fr is the feed rate per revolution (mm/rev). Taking a feed rate of 0.2mm/rev and a spindle speed of 1350rpm as an example, the feed rate is about 270mm/min.

What does SFM Mean In Machining?

SFM (Surface Feet per Minute) in machining refers to the length of the surface that the tool passes through during the cutting process, and can also be understood as a way to express cutting speed. It is a commonly used unit of measurement for cutting speed in the United States, but it is not common in the International System of Units. SFM is measured in feet per minute, while most countries use meters per minute as a common unit of measurement for cutting speed.

Are Cutting Speed and Feed Rate the Same?

Cutting speed and feed speed are two different concepts:

Cutting speed (Vc) refers to the speed at which the cutting edge of the tool moves relative to the workpiece surface. It determines the amount of material cut by the tool per unit time and directly affects the processing speed.

Feed rate (vf: refers to the distance the tool moves on the workpiece per unit time. It determines the speed of the tool’s movement on the workpiece, which in turn affects the material removal rate.