14 Gauge Steel Thickness: An Ultimate Guide

Struggling to choose the right material thickness for your precision parts? Not sure if 14 gauge steel will provide the strength and durability your application requires? Discover why this versatile thickness could be your ultimate solution.

Measuring approximately 0.0747 inches (1.905 mm) thick, 14 gauge steel is a durable and adaptable material used in a wide range of industries, including automotive, medical and industrial equipment. Its balanced strength-to-weight ratio provides a standard and effective solution for a wide range of demanding applications.

Let’s take a deeper look at 14 gauge steel thickness and you can find the answers you’re looking for.

What is 14 Gauge Steel and How Thick Is It?

In the realm of sheet metal fabrication, steel gauge thickness refers to a standardized measurement system. It’s often counter-intuitive because a higher gauge number actually indicates a thinner material.

For instance, 14 gauge steel has a precise thickness of 14 gauge steel of 0.0747 inches, which translates to about 1.905 millimeters. This makes 14 ga steel thickness a medium-heavy gauge, striking a crucial balance between inherent strength and the ability to be easily formed through processes like stamping or bending in CNC machining.

Understanding Metal Gauge Thickness: Why Not Just Millimeters?

The metal gauge thickness system dates back centuries, providing a consistent way to specify materials before precise measuring tools were widespread. While direct decimal measurements in millimeters or inches might seem simpler today, the sheet metal gauge thickness system remains deeply embedded in industrial standards.

In industry have different gauge standards exist, such as the US Standard Gauge or Manufacturers’ Standard Gauge, each with slightly varying equivalents. This consistency simplifies material sourcing and communication across various manufacturing sectors, from sheet metal dimensions to specific steel sheet gauge requirements for complex assemblies.

14 Gauge Sheet Metal Thickness

The thickness of 14-gauge sheet metal varies depending on the material type. Different metals follow different standard gauge systems, resulting in slight variations in actual thickness. The following is the most common materials used in manufacturing and fabrication.

| Material Type | Standard Thickness (inches) | Standard Thickness (mm) | Notes |

|---|---|---|---|

| Steel (Carbon Steel) | 0.0747 in | 1.897 mm | Most common reference for 14 gauge steel sheets in construction and fabrication. |

| Stainless Steel | 0.0781 in | 1.985 mm | Slightly thicker than carbon steel; gauge varies depending on stainless steel standard. |

| Aluminum | 0.0641 in | 1.627 mm | Aluminum sheets are thinner than steel at the same gauge due to different standardization. |

| Galvanized Steel | 0.0747 in | 1.897 mm | Zinc-coated steel sheet; same thickness as standard carbon steel. |

| Copper | 0.0641 in | 1.627 mm | Gauge refers to thickness standards for copper sheets; differs from steel. |

Comparing 14 Steel with Other Common Steel Grades

Understanding how 14 steel compares with other common steel grades helps in selecting the right material for your manufacturing needs. Below is a breakdown of its main characteristics and how it differs from alternatives like mild steel, 4140 alloy steel, and 304 stainless steel.

1. Strength and Hardness

14 steel provides a good balance of strength and toughness, making it suitable for parts exposed to moderate loads and wear. It performs better than mild steel in terms of strength but may not match the high tensile properties of alloy steels such as 4140 or 4340.

2. Machinability

One of the key advantages of 14 steel is its excellent machinability. It cuts cleanly and allows for precise CNC machining with minimal tool wear. Compared to harder alloy steels, it is easier to shape and finish, which helps reduce production time and cost while maintaining accuracy.

3. Corrosion Resistance

While 14 steel has limited resistance to rust compared with stainless steels like 304 or 316, it can still perform well when properly protected. Applying coatings, platings, or surface treatments such as painting or galvanizing can significantly improve its corrosion resistance and extend the lifespan of finished parts.

4. Cost and Availability

14 steel is widely available and cost-effective, offering a solid balance between performance and price. It’s more affordable than high-alloy steels and stainless grades.

5. Applications

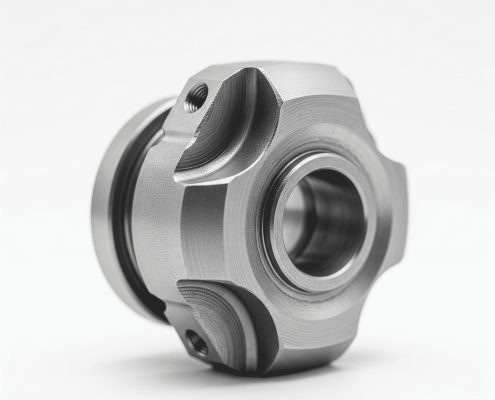

Because of its versatility, 14 steel is often used in automotive components, machine brackets, industrial fittings, and general engineering structures. It provides reliable performance where moderate strength and good machinability are required, serving as a practical middle ground between mild and high-alloy steels.

In summary, 14 steel offers reliable strength, ease of processing, and economic value, making it an excellent choice for many manufacturing applications, especially where high corrosion resistance or ultra-high strength is required.

How to Calculate the Weight of 14 Gauge Sheet Metal?

Calculating the weight of 14-gauge sheet metal is simple once you know the material type, sheet size, and thickness. The formula is the same for most metals , only the density and thickness values change.

1. Use the Basic Formula

This formula helps you estimate the weight of any metal sheet accurately.

2. Know the Thickness of 14 Gauge

The thickness of 14 gauge depends on the material type:

-

Steel: 1.9 mm (0.0747 inches)

-

Stainless steel: 2.0 mm (0.0781 inches)

-

Aluminum: 1.6 mm (0.0641 inches)

3. Common Densities of Metals

-

Mild Steel: 7,850 kg/m³

-

Stainless Steel: 8,000 kg/m³

-

Aluminum: 2,700 kg/m³

4. Example Calculation

Let’s calculate the weight of a 1m × 1m sheet of 14-gauge steel:

1×1×0.0019×7850=14.9 kg (approximately)1 \times 1 \times 0.0019 \times 7850 = 14.9 \text{ kg (approximately)}

So, a 1-square-meter sheet of 14-gauge steel weighs about 14.9 kg.

Tip:

For larger sheets, just multiply the per-square-meter weight by the total area. For example, a 2m × 1m 14-gauge steel sheet weighs roughly 29.8 kg (2 × 14.9).

Frequently Asked Questions About 14 Gauge Steel

How to Protect Against Rust on 14 Gauge Steel?

To prevent rust on 14 gauge steel, apply surface finishes like powder coating, painting, galvanizing or anodizing for aluminum. Regular cleaning, keeping parts dry and using protective covers or oils can also extend lifespan. In CNC and sheet metal processing, rust prevention is often included in post-treatment steps to ensure long-term performance.

What is Sheet Metal Thickness?

Sheet metal thickness is the measurement of how thick a metal sheet is from one surface to the other. It is typically expressed in gauge numbers or in millimeters. In general, a lower gauge number means a thicker sheet. Accurate thickness is important for proper part strength, fit and performance during CNC machining and fabrication.

What is 14 Gauge in mm?

14 gauge steel has a thickness of approximately 1.9 millimeters. This can vary slightly depending on the type of material, but for standard steel, 14 gauge is widely recognized as 1.9 millimeters thick. Knowing this helps engineers and fabricators choose the right material for strength and design.

How Thick is 14 Gauge vs 16 Gauge?

14 gauge steel is thicker than 16 gauge. While 14 gauge measures about 1.9 millimeters, 16 gauge is around 1.5 millimeters thick. The thicker 14 gauge is often used where more strength or durability is needed, especially in heavy-duty sheet metal or CNC-machined parts.

Is 14 Gauge Steel Strong Enough?

Yes, 14 gauge steel is strong and durable enough for most structural and industrial uses. It offers a solid balance between strength and weight, making it suitable for CNC-machined components, enclosures, frames and other parts used in automotive, machinery and construction applications.