VMT’s Uncompromising Commitment to Quality

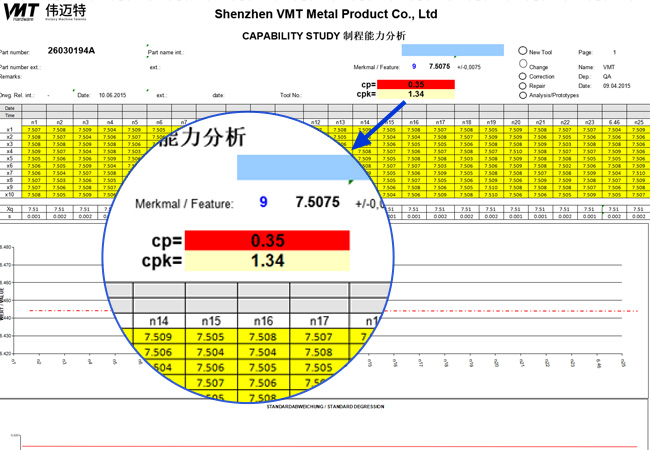

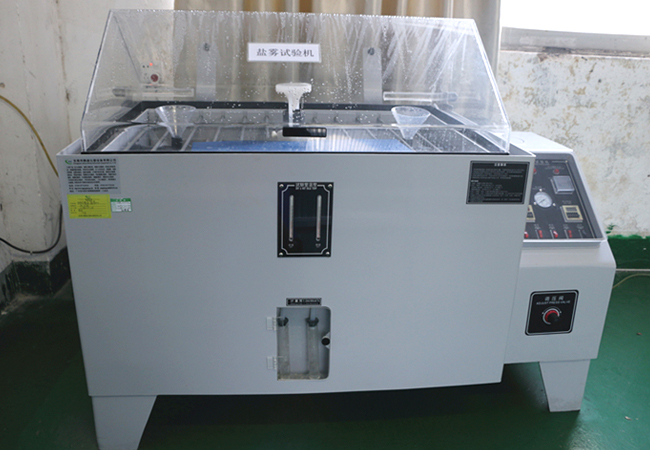

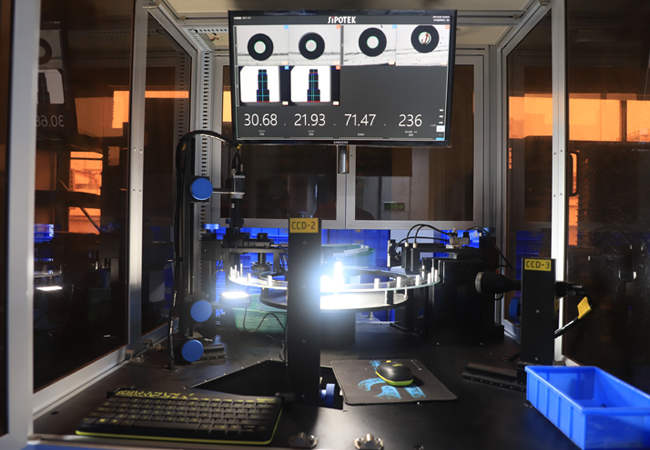

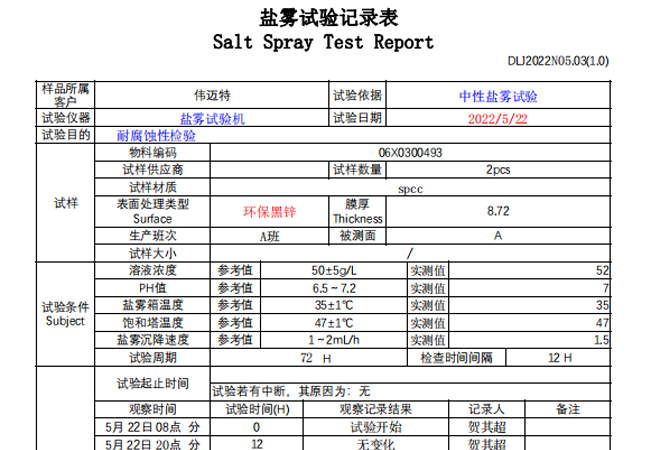

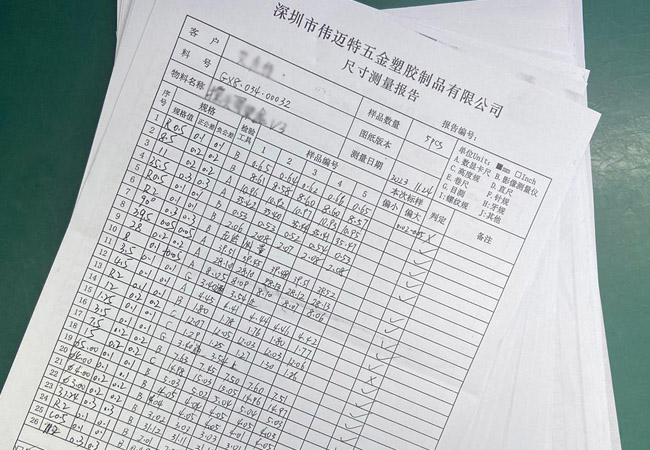

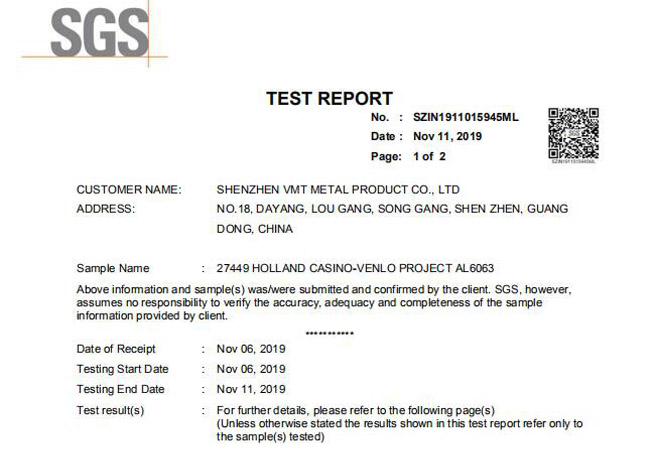

Quality is always our first priority, we have 2 full-time SQE engineers, adopt a complete supplier process control process, and combine with 30 appearance inspection personnel to achieve a parts yield rate of 99.98%.

- ISO 9001:2015 certification

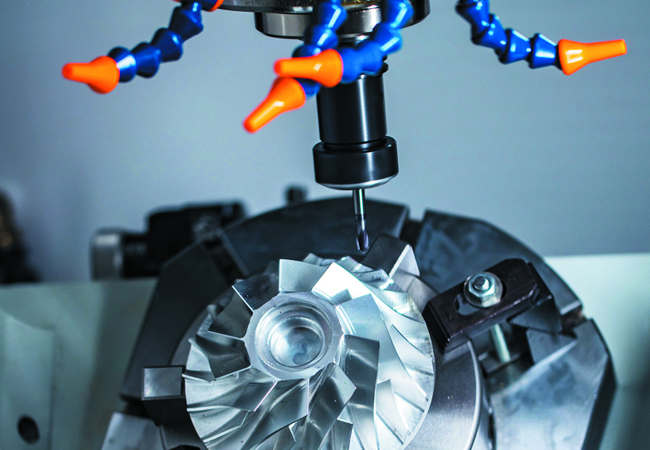

- Producing over 500,000 quality parts

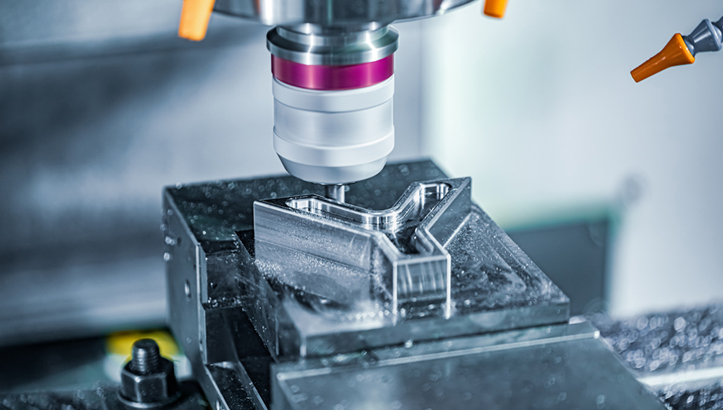

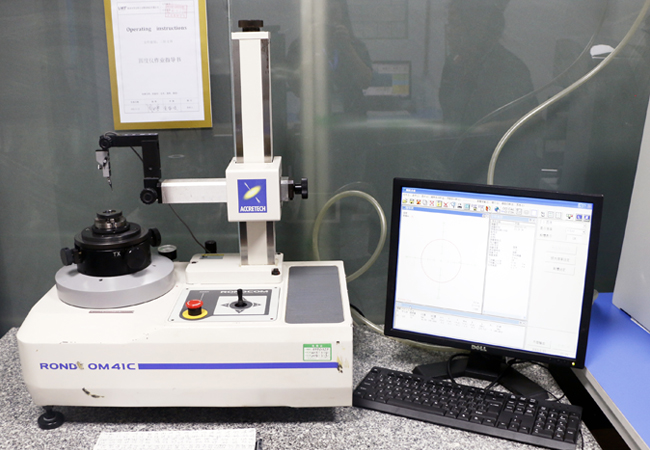

- Tolerances as low as ±0.0004″ (0.01mm)

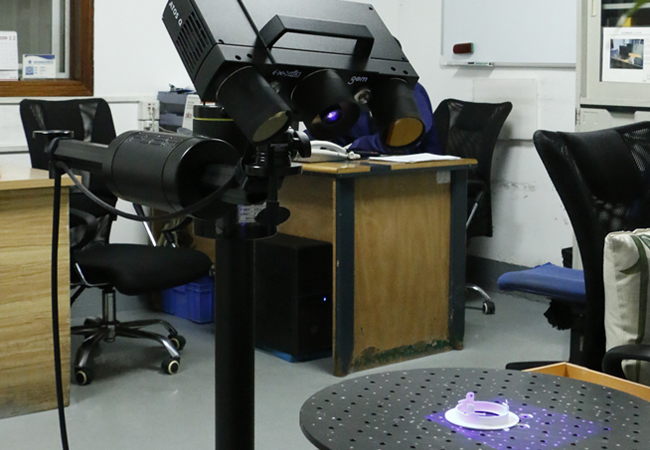

- 12-Step Quality Inspection Process

- 6 DFM Analysis Engineers with 20 Years of Experience