How to Remove Broken Taps?

A broken tap can cause significant delays in manufacturing, particularly in the field of precision machining. It is essential to remove a broken tap without causing any damage to the workpiece. This article outlines effective methods for efficiently extracting broken taps from a range of materials.

Removing a broken tap can be tricky; however, utilizing the appropriate tools and techniques can ensure a safe removal process. Options such as tap extractors, left-hand drill bits, and EDM (electrical discharge machining) offer effective solutions, tailored to the specific material and circumstances at hand.

Let’s explore some of the most effective ways to remove a broken tap, whether it’s stuck in a blind hole, engine block, or other materials like aluminum and steel.

What Causes a Broken Tap?

Broken taps often arise when cutting forces surpass the tap’s capacity, or when the material being tapped is excessively hard. Identifying these causes can assist in preventing future occurrences of breakage.

Tap breakage frequently results from applying excessive pressure, using incorrect speeds, or selecting improper tools. Frequent causes of tap breakage include incorrect feed rates, worn-out taps, and insufficient lubrication. Adhering to optimal machining conditions is crucial for prolonging tool life and preventing breakage.

6 Effective Ways to Remove Broken Taps

There are several methods for removing a broken tap. Each method is suited to different materials, tap sizes, and breakage scenarios. Six effective ways to remove broken taps include using a tap extractor, left-hand drill bits, EDM, a broken tap remover, applying heat, and mechanical extraction tools.

1. Tap Extractor

A tap extractor is one of the most common and effective tools used for removing broken taps. It works by engaging with the threads of the broken tap and rotating it counterclockwise to loosen and pull it out. Tap extractors come in various sizes, making them versatile for different tap sizes and materials. This method is ideal when the tap is not deeply embedded or when conventional drilling techniques are not viable.

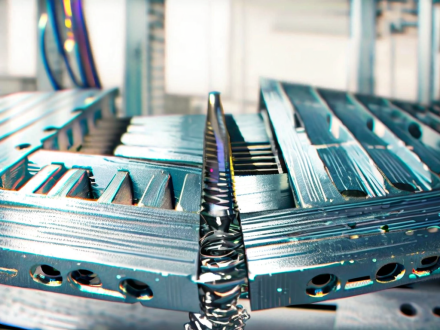

2. Left-Hand Drill Bits

Left-hand drill bits rotate in the opposite direction of regular drill bits, making them an excellent tool for extracting a broken tap. When using a left-hand drill bit, you essentially use the rotation to unscrew the tap by reversing its threads. This method is highly effective when combined with light pressure. As the drill bit removes material from around the broken tap, the tap itself may begin to loosen and turn out. Left-hand drill bits are ideal for applications where the tap is slightly loose or when you are working with softer materials.

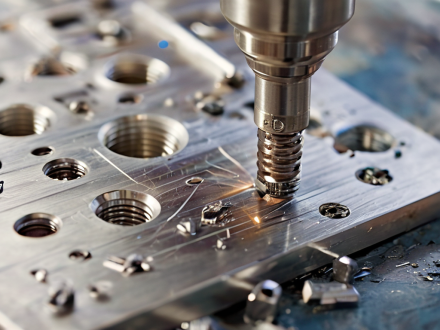

3. EDM (Electrical Discharge Machining)

Electrical Discharge Machining (EDM) is an advanced technique often used for removing broken taps in hard materials. EDM uses electrical sparks to erode the material of the broken tap without affecting the surrounding workpiece. This technique is particularly useful for extracting taps that are stuck in hard or deep holes, such as in engine blocks or hardened steel. Although EDM requires specialized equipment and expertise, it provides a highly precise and effective way to remove broken taps, especially when other methods fail. EDM is an excellent choice when precision is critical and the material is too hard for conventional extraction methods.

4. Broken Tap Remover

A broken tap remover is a specialized tool designed to help extract broken taps by gripping the tap and turning it in the opposite direction. These tools are especially effective when dealing with taps that are not completely shattered or when the tap is exposed enough to grab. Broken tap removers typically have adjustable jaws that clamp around the tap, providing a secure grip.

5. Applying Heat

Applying heat to the workpiece can be an effective method for removing a broken tap, especially when the tap is made of a material that responds well to heat. Heat can expand the metal around the tap, allowing it to loosen and making the tap easier to extract. Heat treatment is often used in combination with other extraction methods, such as tap extractors or left-hand drill bits. For example, you might heat the workpiece to a specific temperature and then immediately attempt to extract the tap while the metal is still expanded.

6. Mechanical Extraction Tools

Mechanical extraction tools are specialized devices that grip and pull out a broken tap without the need for drilling or chemical processes. These tools typically use a set of jaws or clamping mechanisms to latch onto the broken tap, allowing them to apply force and twist the tap out of the hole.

EDM Tap Removal

Electrical Discharge Machining (EDM) represents an advanced technique for removing broken taps, particularly when traditional methods prove ineffective. EDM operates by employing electrical sparks to erode the material of the broken tap without impacting the surrounding workpiece. This method is ideal for situations involving extremely hard or deeply embedded taps. Additionally, EDM offers high precision, making it suitable for taps that are lodged deep within workpieces, such as engine blocks or hardened steel components.

Extracting a Broken Threading Tap

Extracting a broken threading tap necessitates precision and the appropriate tools to prevent additional complications. The process can be carried out using a tap extractor or by drilling out the tap with a left-hand drill bit. A crucial aspect of this procedure is to target the tap from the center, which helps mitigate the risk of damage to the surrounding area.

An effective extractor tool for threading taps should feature adjustable grips that accommodate various tap sizes. This ensures a higher likelihood of successful extraction while minimizing the risk of damage to the surrounding material.

How to Remove Broken Tap from a Blind Hole?

The extraction of a broken tap from a blind hole presents distinct challenges. Since blind holes prevent access to the backside of the tap, specialized techniques are essential for effective removal.

To remove a broken tap from a blind hole, utilizing a tap extractor or a left-hand drill bit is recommended. The extractor grips the broken tap, while the drill bit aids in reversing the thread. Specialized broken tap extractors designed for blind holes can be especially beneficial, as these extractors employ internal threads to securely grip the broken tap without damaging the hole. Furthermore, applying heat to the workpiece may sometimes assist in loosening the tap, thereby facilitating the extraction process.

How Can I Remove a Broken Thread Tap from a Metal Surface?

Removing a broken threading tap from metal surfaces, such as steel or aluminum, demands careful handling to prevent damage to the workpiece.

When removing a broken tap from metal, a tap extractor or a left-hand drill bit is often the most effective solution. For harder materials, Electrical Discharge Machining (EDM) can serve as a viable method for extraction.

For steel, tap extractors and drilling tools can be quite effective. In the case of aluminum, it is important to avoid applying excessive force due to the softer nature of the material. A combination of gentle tapping and careful drilling can facilitate the removal of the tap while preserving the integrity of the surface.

How to Remove a Broken Tap from an Engine Block?

Extracting a broken tap from an engine block is a meticulous task that necessitates a careful approach to prevent damage to the engine.

To remove a broken tap from an engine block, a combination of tap extractors, left-hand drill bits, and heat treatment is recommended. Electrical Discharge Machining (EDM) is also an effective method for extracting taps from tough, hardened materials. EDM allows for precise removal of the tap while safeguarding the engine block from damage. Additionally, applying heat treatment can help soften the surrounding metal, facilitating the easier extraction of the tap.

How to Remove a Broken Tap from Aluminum?

Aluminum is a softer metal, making it more susceptible to damage; however, employing the correct techniques can enable the removal of a broken tap without compromising the surface.

For aluminum, the most effective methods typically involve the use of a tap extractor or a left-hand drill bit. Additionally, careful and controlled drilling can assist in preventing further damage to the aluminum surface during the extraction process.

Aluminum necessitates gentler handling, as excessive force can result in material deformation. To achieve optimal results, it is advisable to avoid overheating the aluminum and to utilize a suitable coolant to reduce friction during the removal process.

In Conclusion

There are multiple methods available for removing broken taps, which can range from mechanical tools such as extractors to advanced techniques like Electrical Discharge Machining (EDM). The choice of method often depends on the material and the location of the tap.

VMT Provides Convenient and Professional Solutions

Learning how to remove broken taps is crucial due to the frequency of this issue. However, entrusting the task to experts is always a wiser decision. CNC machining services stand out as the optimal choice for any manufacturing setting, particularly for small and medium-sized enterprises, as they enable access to top-notch technology and skilled operators without the need for significant investments.

When considering CNC machining services, VMT emerges as the most natural choice. Our response speed is unmatched, with 24/7 online availability and quotes provided within just 2 hours. At VMT, we are dedicated to providing you with the most efficient and professional CNC machining services to ensure that your needs are met with precision and care. Trust us to handle the removal of broken taps and other complex machining tasks with expertise and confidence.

Frequently Asked Questions About Remove Broken Taps

How to Remove Broken Tap Without Extractor?

Methods such as utilizing a left-hand drill bit or applying heat to loosen the broken tap can be effective alternatives in the absence of an extractor. Additionally, employing a small center punch along with a hammering technique may assist in the extraction process. Moreover, drilling out a broken tap with conventional drill bits can serve as a viable workaround. The key is to drill slowly and carefully to prevent damage to the surrounding material.

How to Remove a Tap that is Stuck?

Removing a stuck tap can be a challenging process, but several effective techniques and tools are available to safely extract it without causing additional damage. The initial step is often to apply penetrating oil around the stuck tap and allow it to sit for a few minutes to help loosen the bond. Subsequently, attempting to use a tap extractor can be beneficial; these tools feature prongs that fit into the flutes of the tap for enhanced grip. If this method proves ineffective, heating the surrounding metal slightly may induce expansion, potentially releasing the tap. For particularly stubborn taps, employing a left-handed drill bit can assist in dislodging the broken piece while drilling into it. As a last resort, Electrical Discharge Machining (EDM) can be utilized to remove the tap without harming the threads. Additionally, carbide burrs may be considered for manual removal, although this approach requires precision and steady handling to avoid further complications.

What Drill Bit Will Drill Out a Broken Tap?

Using the correct drill bit is essential for drilling out a broken tap, especially when dealing with hardened materials. Carbide drill bits are typically recommended due to their durability and ability to penetrate tough metals. A carbide drill bit, especially a left-handed one, is often best for drilling out a broken tap as it’s durable enough for hardened metals. However, drilling carefully at low speed and using coolant is essential to avoid damaging the surrounding area or the drill bit itself.

Beyond carbide bits, cobalt bits are another strong option, particularly if you need a smaller or more flexible bit. In cases where precision is critical, using a specialized diamond core bit can help as well, though this is less common.