What is Hot Forging?

- Hot forging is a forging process in which the metal material is heated above its recrystallization temperature and then pressed.

- The temperature of hot forging may be as high as 2200°F (about 1204°C) to 2400°F (about 1316°C).

- Plastic deformation above the recrystallization temperature can permanently change the shape of the metal.

VMT’s Hot Forging Services

- VMT specializes in hot forging services, providing high-quality products for electronics, automotive, medical and other industries.

- We work closely with our customers to understand their specific needs and provide suitable solutions.

- We use advanced technology to produce durable, high-performance parts by heating metals to the appropriate temperature to enhance their ductility and strength.

- We are committed to providing accurate and efficient services and are a reliable partner in the manufacturing industry.

Our Robust Capabilities Behind Numbers

With many years of industry experience, VMT’s team of experts excels in providing high-quality and efficient hot forging solutions. Our hot forging services are widely used in multiple industries such as electronics, automotive, aerospace and medical to meet the diverse needs of different customers. We pay attention to details and quality, and are committed to providing customers with professional and reliable services.

6,000+

Companies Served

300,000+

Unique Parts Produced

62+

Countries Shipped

14+

Years in Business

600+

Suppliers Cooperated

Why Choose VMT for HOT Forging?

Need to make copies of your metal product?Hot forging is your solution. Here at VMT, we lead the industry in efficient, high-quality forging services scalable for any organization. Here are just a few reasons why thousands of businesses worldwide choose us for forging.

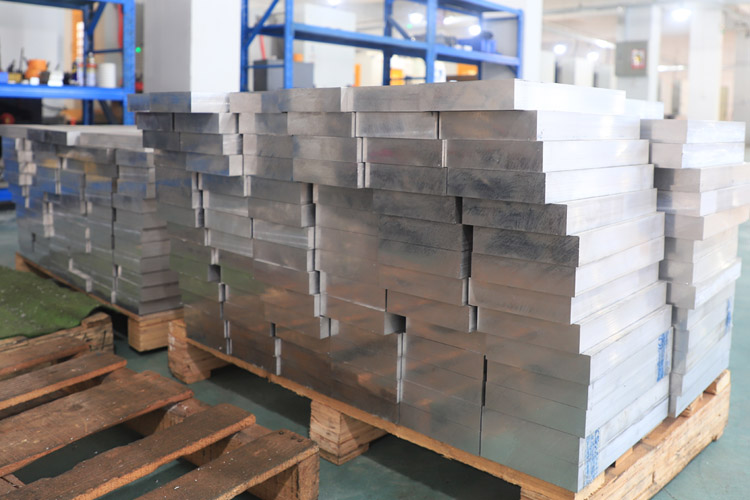

1、Raw materials

VMT’s quality control from begining.Check raw materials’conpoents,size, appearance,etc before start prdouuction.

2、Workshop

VMT owns more than 50 pcs antomatic machines,making prouducts according to customers’drwaings.Welcome bulk order!

3、Zero defect goal

VMT owns many inspection machine to inspect product’ size,appearance,Anti-corrosion ability,air-tightness and so on.

4、Profesional team

VMT provides one stop service and help you solve all potential problems until you are satisfied.

5、Packing

Choosing proper packing method to make sure products are in good condition before shipping,during transportation,when arrive in your hands.

Our Hot Forging Services

VMT’s team of experts excels in providing high-quality and efficient hot forging solutions. Our hot forging services are widely used in multiple industries such as electronics, automotive, aerospace and medical to meet the diverse needs of different customers.

Hot Forging

VMT uses efficient hot forging equipment and experienced technicians to machine raw materials into precision parts.

What are the Differences Between Hot and Cold Forging?

The cold forging manufacturing process increases the strength of a metal through strain hardening at a room temperature. On the contrary the hot forging manufacturing process keeps materials from strain hardening at high temperature, which results in optimum yield strength, low hardness and high ductility.

Finally, a manufacturer would choose one process over the other because of economic and not quality reasons. The decision is based on the required functions of the desired component, the industry and if it’s a mass production or a low volume of customized parts.

VMT provides cold, warm and hot forging or combination of different processes to address various customer demands, both performed in excellent conditions with state-of-the-art machinery for perfect results. We work close with our customers to understand their specific needs and find the best possible solution.

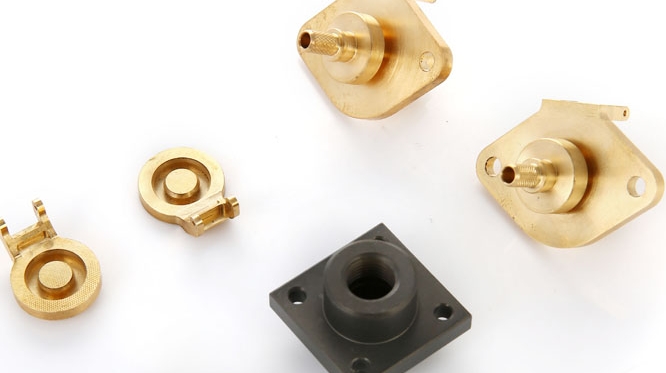

Product Cases

Copper forging machining

Aluminum forging machining

The Hot Forging Manufacturing Process

The hot forging manufacturing process is performed at extreme high temperature (up to 1150 °C for steel, 360 to 520 °C for al-alloys, 700 to 800 °C for cu-alloys). This temperature is necessary in order to avoid strain hardening of the metal during deformation. Stamping is the most widespread hot forging manufacturing process, where the material is squeezed in a press, between a tool and a die surface.

Cost Efficiency in Hot Forging

The minimization of energy costs during hot forging is an ongoing concern of every manufacturer. Those can be optimized when using an inductor and a billet with matching diameters and installing a flexible multi-stage heating system.

All applied tools should be optimized for the following innovative technologies:

Metallurgy: consolidated vacuum, powder metallurgy

Reloading

Heat treatment

Surface treatment: nitriding, carburizing and duplex treatment

Hot Forging Materials

Hot forging can be used to fabricate a broad spectrum of parts, and can be performed with most metal materials, including:

- Carbon steel

- Aluminum

- Titanium

- Copper

- Nickel alloys

Advantages of Hot Forging:

- Good ductility

- Excellent surface quality

- Increased flexibility

- Good for custom parts

Get Your Hot Forging Project Started Today

Our hot forging engineers are ready to work with you to make sure you get great parts fast. When you submit your 3D design files, we will consult with you to ensure design for manufacturability in order to get parts that meet and exceed your expectations. Contact us for your free quote and design review today.