Casting vs Forging: What’s the Difference?

Casting and forging, as the two pillars of metal machining, each has unique process characteristics and application value. The core difference between them is mainly reflected in the nature of the forming method. Casting uses the fluidity of liquid metal to form complex shapes, which is suitable for mass production; forging shapes in the solid state, emphasizes high strength and high toughness, and is suitable for key components. This article will introduce the differences between casting and forging in depth. By understanding the differences between the two, you will be able to make more informed decisions and help ensure product quality and performance.

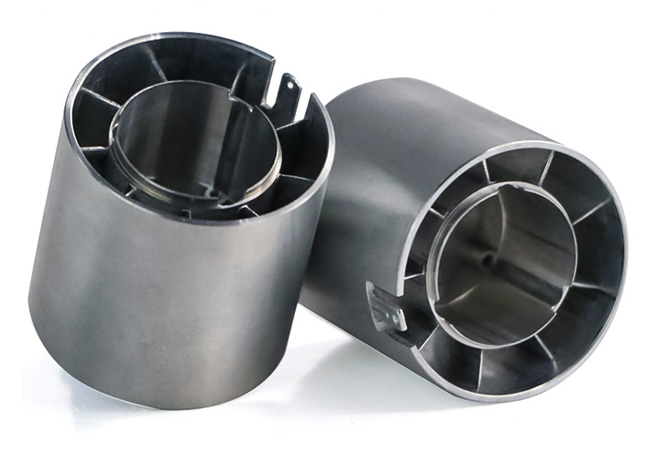

What is Casting?

Casting is a metal machining process that heats the metal to a liquid state, then pours it into a pre-designed mold, waits for the metal to cool and solidify, and then removes the mold to obtain a metal part or product of the desired shape and size. In this process, the liquid metal cools and solidifies under the constraints of the mold, thereby replicating the shape of the mold.

Advantages of Cast Metal

Excellent mechanical properties: During the casting process, the liquid metal cools and solidifies rapidly in the mold, making the surface crystal structure of the casting dense, thereby improving the mechanical properties of the casting, including corrosion resistance and hardness.

High precision: The casting process can produce castings with high dimensional accuracy and low surface roughness. This is because the precise design and manufacture of the casting mold, as well as the good fluidity of the liquid metal in the mold, enable the casting to accurately replicate the shape and size of the mold.

High production efficiency: The casting process is suitable for mass production and can significantly improve production efficiency.

Saving materials: The casting process has a high advantage in material utilization. Since the liquid metal can fully fill every corner of the mold, the waste of materials is reduced. In addition, metal mold casting can also achieve “one mold for multiple castings”, that is, one metal mold can be reused many times, further saving molding materials and molding time.

Wide range of applications: The casting process is able to produce castings of various shapes and sizes, including complex structures and thin-walled parts. This makes the casting process widely used in various fields, such as automobile manufacturing, aerospace, machinery manufacturing, etc.

What is Forging?

Forging is also a metal machining method that uses a forging machine to apply pressure to a metal blank to cause it to undergo plastic deformation, thereby obtaining a forging with certain mechanical properties, shape, and size. This machining method changes the physical properties and internal structure of the metal, making it more suitable for various engineering applications.

Advantages of Forged Metals

Improve metal properties: Forging can eliminate defects such as cast porosity produced in the metal smelting process, optimize the microstructure, and improve the strength and toughness of the metal.

Improve product quality: The internal structure of forgings is uniform and dense, without defects such as pores and inclusions, with a smooth surface, precise dimensions and excellent mechanical properties.

Strong adaptability: The forging process is suitable for various metal materials, including high-strength alloy steel, stainless steel, etc., and can produce forgings with complex shapes and high precision.

Casting vs Forging: Which is Better?

When discussing whether casting or forging is better, there is actually no absolute answer, because these two processes each have their own unique advantages and limitations and are suitable for different production needs and scenarios.

Advantages of Casting

Cost-effectiveness: The casting process is relatively simple, with high material utilization, suitable for large-scale production, so the cost is relatively low, especially suitable for the production of a large number of standard parts.

Design flexibility: Casting can produce parts with complex shapes and various sizes, providing designers with greater creative space to meet diverse market demands.

Disadvantages of Casting

Internal quality control: Castings may have internal defects such as porosity and shrinkage, which may affect the mechanical properties and reliability of the parts.

Strength limitations: Castings are generally lower in strength than forgings and therefore may be limited in use in high-stress or high-load environments.

Advantages of Forging

High strength and high performance: The forging process makes the internal structure of the metal uniform, giving the parts excellent strength and toughness, significantly improving the fatigue resistance and wear resistance of the material, and extending its service life.

Precise Control: The forging process allows for precise control of the size and shape of the parts, ensuring high precision and quality of the parts.

Disadvantages of Forging

Higher cost: Forging equipment and processes are relatively complex, involving high material, mold and technology costs, and are suitable for small-batch production or high-end applications.

Long production cycle: The forging process includes multiple precise steps such as heating, forging and cooling, so the production cycle is relatively long.

Material limitations: Not all materials are suitable for forging, especially those with high melting points or difficult to plastically deform, which limits the application scope of forging.

Factors You Need to Consider When Choosing Casting or Forging.

When choosing between casting and forging, there are several aspects to consider:

Product requirements: If the product needs to withstand high loads, high impacts, or needs to have excellent mechanical properties, then forging may be a better choice. If the product has a complex shape, large size, and does not require particularly high mechanical properties, then casting may be more appropriate.

Cost-effectiveness: The casting process is relatively simple, with low production costs, and is suitable for mass production. On the other hand, the forging process is relatively complex and has high production costs, but it can produce parts with excellent mechanical properties. Therefore, a trade-off needs to be made in terms of cost-effectiveness.

Production efficiency: The casting process can produce parts in large quantities and has high production efficiency. However, the forging process may require more time and manpower investment and has relatively low production efficiency.

In summary, casting and forging each have their own unique advantages and scope of application. When choosing, it is necessary to comprehensively consider factors such as specific application scenarios, product requirements, cost-effectiveness, and production efficiency.

In Conclusion

Forging and casting are both important processes in metal processing, but they differ significantly in manufacturing principles, application scenarios, and final product characteristics. Casting is a process of melting metal and pouring it into a mold, which is suitable for producing complex shapes and large-sized parts; while forging deforms the metal through hammering or mechanical force, giving the parts higher strength and toughness. Therefore, when choosing casting or forging, it is necessary to comprehensively consider many factors such as the specific needs of the product, production scale, cost-effectiveness, and material properties.

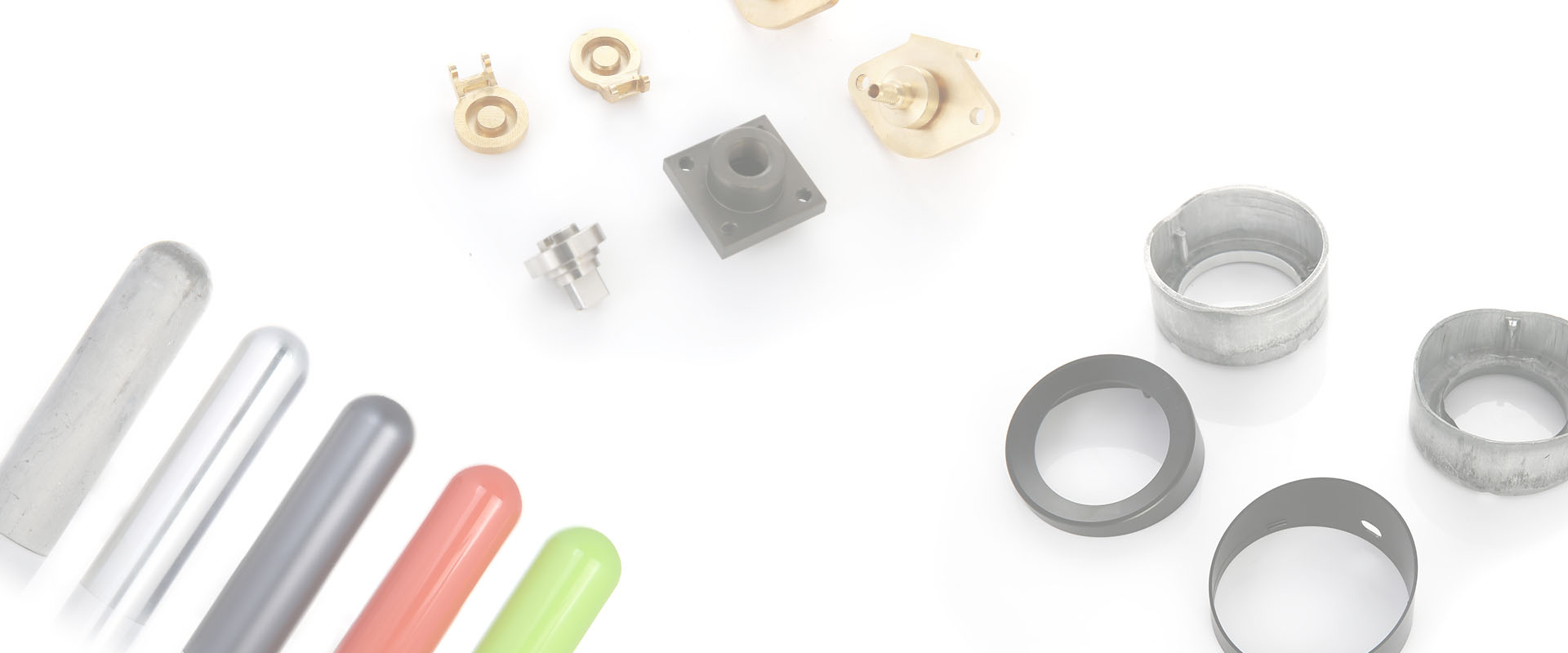

Choose VMT as Your Partner for Your Forging or Casting Projects.

VMT, as a long-term supplier of high-quality forged or cast parts, focuses on in-house manufacturing, ensuring high-quality standards are met at every stage of production.

Our CNC machining factory is equipped with advanced casting and forging equipment, as well as an experienced technical team. We provide a variety of customized solutions including casting CNC machining parts, forging CNC machining parts, and CNC prototype machining to meet the diverse needs of different customers.

If you have any forging or casting needs, please feel free to contact us. We are pragmatic and professional, providing the best solutions to help you innovate and develop.

Frequently Asked Questions About Casting and Forging

Is Forging Stronger Than Casting?

Yes, generally speaking, forged products are stronger than cast products. This is because during the forging process, the metal is subjected to pressure, the molecules are more compact and arranged neatly, making the forged products have higher strength and toughness. In addition, the internal quality of forged products is more uniform, without defects such as pores and inclusions, which improves its strength. Therefore, forging is mainly used to manufacture important parts that are subjected to large forces and have high mechanical performance requirements, such as crankshafts, wheel hubs, gears, etc.

Is Casting Cheaper Than Forging?

Casting can often be cheaper than forging, especially for large-scale production of simple or complex shapes. Casting involves pouring molten metal into a mold, allowing it to cool and solidify into the desired shape. This process is relatively straightforward and can be automated, reducing labor costs. Additionally, casting can produce parts with intricate internal features that would be difficult or impossible to achieve through forging. However, the cost-effectiveness of casting versus forging depends on several factors, including the material, part complexity, production volume, and required properties.

What is the Difference Between Cast and Forged Surface Finish?

There are obvious differences in surface finish between casting and forging: casting is prone to defects due to uneven wall thickness and cooling differences, which affect the surface quality; while forging obtains a smoother surface through compression force, and can be further processed and improved. Forged parts often require a finish of Ra0.8 or above to enhance beauty and durability. Casting requires optimized processes to improve surface quality. In general, forging is better in quality than casting but more expensive, so the choice needs to be considered comprehensively between needs and budget.