Automotive Car Chassis Explained: Structure, Types, And Components

The car chassis is the backbone of a vehicle, supporting its entire structure and essential components. It plays a crucial role in determining a car’s performance, safety, and handling. Despite its importance, many people are unfamiliar with its intricate design and the materials used.

The automotive car chassis is the structural framework that holds the vehicle’s key systems like the engine, transmission, and suspension. It serves as the foundation for the car’s performance and safety. Understanding how it works can help enhance the vehicle’s design and durability.

In this article, we will break down the automobile chassis, detailing its structure, components, types, and functions.

What is an Automotive Car Chassis?

The automotive chassis is a crucial part of the car’s structure that supports all of its components, including the engine, transmission, steering system, and suspension. The chassis provides the vehicle’s structural integrity, ensuring that it can withstand the various stresses experienced during driving, such as acceleration, braking, and turning.

The term “chassis” can refer to different things in the context of car design, but it typically encompasses everything beneath the vehicle’s body that supports its functionality. The chassis of a car is often designed as either a monocoque or a frame-based structure, both of which offer different advantages based on the type of vehicle.

Structure of Automotive Car Chassis

The structure of an automobile chassis consists of multiple components that work together to form a strong, rigid framework that supports the entire vehicle. The main structural elements include:

1. Frame Rails

Frame rails are the long, parallel beams that run along the sides of the car, serving as the primary load-bearing components. These rails are designed to handle the vehicle’s weight and the forces generated during driving. The frame chassis design ensures that the car remains rigid and stable under different driving conditions.

2. Crossmembers

Crossmembers are horizontal bars that connect the frame rails and provide additional support and stability. They are strategically placed throughout the chassis to support key components, such as the transmission, suspension, and steering system. The crossmembers play a vital role in absorbing forces during impact, preventing structural damage to the vehicle.

3. Clutch and Transmission System/Gearbox

The transmission system is mounted on the chassis to transfer power from the engine to the wheels. The clutch allows the engine to disconnect from the transmission when shifting gears. These components work in tandem to control the car’s speed and torque, which are essential for optimal performance and efficiency.

4. Universal Joint

The universal joint connects the driveshaft to the axle, allowing power to be transferred from the engine to the wheels. It is designed to accommodate changes in angle and rotation, ensuring smooth and consistent power delivery to the wheels.

5. Rear Axle

The rear axle is a critical component of the chassis that connects the vehicle’s rear wheels to the drivetrain. It allows the wheels to rotate and enables the car to move. The rear axle also houses the differential, which distributes power between the wheels, allowing them to rotate at different speeds during turns.

6. Steering System

The steering system is mounted on the chassis, providing the driver with control over the car’s direction. The steering mechanism, whether it’s a rack-and-pinion or steering box system, is connected to the front wheels, allowing the driver to turn the vehicle.

7.Braking System

The braking system is mounted on the chassis car and is responsible for slowing down or stopping the vehicle. Components like the brake rotors, pads, and calipers are all attached to the chassis, ensuring that the vehicle can stop safely and efficiently when needed.

Types of Automotive Car Chassis

There are several types of chassis used in the automotive industry, each with its unique advantages based on the vehicle’s intended use. Here are the most common types:

| Chassis Type | Description | Advantages | Common Applications |

|---|---|---|---|

| Ladder Frame | One of the oldest chassis designs, consisting of two parallel rails connected by crossmembers, forming a ladder-like structure. | – High strength and durability – Excellent load-bearing capacity – Simple and easy to manufacture and repair |

Trucks, SUVs, off-road vehicles, commercial vehicles |

| Monocoque | The body and frame are integrated into a single structure, common in modern passenger vehicles. | – Lightweight and fuel-efficient – Improved safety with impact absorption – Enhanced rigidity and better handling |

Passenger cars, sedans, hatchbacks, modern SUVs |

| Space Frame | Uses a network of tubular beams to create a lightweight yet rigid structure, often found in high-performance vehicles. | – High strength-to-weight ratio – Excellent rigidity for better performance – Allows for flexible design modifications |

Supercars, racing cars, high-performance vehicles |

| Backbone Chassis | Features a central spine or backbone that runs along the length of the vehicle, supporting the drivetrain and suspension. | – Simple yet strong structure – Good rigidity for lightweight performance – Compact design for small sports cars |

Sports cars, off-road vehicles, small and mid-engine cars |

Functions of an Automotive Chassis

The automobile chassis serves several crucial functions that contribute to a vehicle’s overall performance, safety, and efficiency. The primary functions include:

Support Different Car Components

The chassis car serves as the foundation for key components like the engine, transmission, suspension, and steering system. Without the chassis, these systems would have nowhere to attach and operate. It ensures that the car remains balanced and that all components function cohesively.

Balance Car Structure

The chassis for car is designed to distribute the car’s weight evenly across its structure. This ensures stability during driving, particularly when the car turns, brakes, or accelerates. A well-designed chassis helps to minimize the risk of rollovers and provides better control in various driving conditions.

Vehicle Structural Integrity

The chassis car design is responsible for maintaining the structural integrity of the vehicle. It must withstand forces such as torsion, bending, and shear, ensuring that the vehicle does not deform under stress. A rigid chassis design prevents frame bending, which can lead to handling issues or safety risks.

Point of Attachment for Other Components

The chassis of a car serves as the attachment point for a variety of vehicle systems, such as the suspension, fuel tank, exhaust, and powertrain components. These attachments need to be secure and capable of withstanding various forces, including vibrations and impacts.

Absorb and Distribute Crash Energy

The chassis of a car is designed to absorb and distribute the energy generated during a crash. Modern chassis designs incorporate crumple zones, which are areas designed to deform in a controlled manner during a collision. This helps to protect occupants by reducing the impact forces that are transferred into the cabin.

Components of an Automotive Car Chassis

The automotive chassis is a complex assembly of various structural and mechanical components that work together to form the foundation of a vehicle. Each part serves a specific purpose, contributing to the car’s stability, performance, and safety. Below are the key components of an automotive car chassis:

| Component Name | Function & Purpose | Structure & Features |

|---|---|---|

| Frame Rails | Serve as the structural backbone of the vehicle, supporting the body, engine, and transmission while absorbing and dissipating forces during driving and impacts. | Made of high-strength steel or aluminum, running longitudinally along both sides of the vehicle. |

| Crossmembers | Connect the frame rails to increase rigidity and structural integrity, preventing twisting under stress; also act as mounting points for suspension, brakes, and fuel tank. | Horizontally placed support bars positioned at various points along the chassis for even load distribution. |

| Suspension Mounts | Secure suspension components (shock absorbers, springs, control arms) to the chassis, absorb road shocks, and maintain wheel alignment for stability and handling. | Positioned according to suspension design, with vibration-damping features. |

| Steering System Components | Connect the steering wheel to the front wheels via mechanisms such as steering column, rack-and-pinion, or steering box for precise control. | Firmly mounted to the chassis to ensure accurate alignment and structural rigidity. |

| Rear Axle and Differential | Transfer engine power to the rear wheels; the differential allows each wheel to rotate at different speeds during turns for smoother handling. | Available in solid axle (durability and load capacity) or independent suspension (better ride comfort). |

| Braking System | Uses brake rotors, calipers, pads, and hydraulic lines to slow or stop the vehicle through friction when the brake pedal is pressed. | Commonly disc brakes (strong stopping power, good heat dissipation) or drum brakes (lower cost). |

| Fuel Tank Mounts | Securely hold the fuel tank in place to ensure safe storage and supply of fuel while minimizing movement or damage risk. | Usually located at the rear or near the rear axle; modern tanks often made of lightweight, corrosion-resistant plastic. |

| Engine and Transmission Mounts | Hold the engine and transmission in position, absorb vibrations, and maintain proper alignment for smooth power delivery and reduced noise. | Designed with damping materials to enhance comfort, durability, and performance. |

Common Materials for Car Chassis

The materials used in the construction of the automotive chassis have a significant impact on the vehicle’s strength, weight, and cost. Here are some common materials:

| Material | Description | Advantages | Disadvantages | Common Applications |

|---|---|---|---|---|

| Steel | Widely used for automotive chassis, particularly in ladder frame designs. | -Strong and durable – Cost-effective – Easily available |

– Heavy – Prone to corrosion if not treated |

SUVs, Trucks, Commercial vehicles |

| Aluminum | Lightweight metal used in monocoque chassis designs to reduce vehicle weight. | – Lightweight – Corrosion-resistant – Recyclable |

– Expensive – Not as strong as steel |

Luxury cars, Sports cars, Electric vehicles |

| Carbon Fiber | High-performance material with excellent strength-to-weight ratio, used in racing cars. | – Extremely lightweight – High strength-to-weight ratio – Excellent performance |

– Expensive – Brittle – Difficult to manufacture |

Formula 1 cars, Supercars, Racing cars |

| Magnesium Alloy | Ultra-lightweight material used in performance and racing vehicles. | – Very lightweight – High strength-to-weight ratio – Stronger than aluminum in some applications |

– Expensive – Difficult to machine – Reacts with water |

Racing cars, Formula 1 vehicles |

| Titanium | Lightweight, corrosion-resistant metal used for specialized components. | – High strength-to-weight ratio – Corrosion-resistant – Durable |

– Very expensive – Difficult to work with |

Aerospace, Military vehicles, Racing parts |

| High-Strength Steel (HSS) | Enhanced steel offering greater strength while maintaining low weight, used in unibody chassis. | – Stronger than regular steel – Lighter than traditional steel – Affordable |

– Prone to corrosion – Expensive compared to regular steel |

Passenger vehicles, SUVs, Mid-range cars |

| Plastics (Polymer Composites) | Lightweight polymer materials used for non-structural components. | – Lightweight – Corrosion-resistant – Moldable – Low cost |

– Less durable – Poor impact resistance – Limited to non-structural use |

Electric vehicles, Eco-friendly cars, Non-structural components |

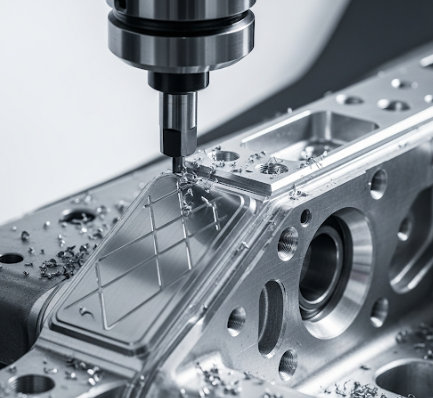

Common Automotive Car Chassis Processes

Manufacturing a car frame involves several key processes:

Stamping: Large sheets of metal are stamped into the desired shape using high-pressure machines. This process is often used to create components like frame rails and body panels.

Welding: The various components of the chassis car are welded together to form a rigid structure. Different welding techniques, such as MIG and TIG welding, are used to ensure strong, durable joints that can withstand the stresses of driving.

Assembly: After fabrication, the individual components are assembled to create the final automobile chassis. This may involve bolting, welding, and securing various parts, such as the rear axle, suspension, and steering systems, to the frame.

Common Surface Finishes for Car Chassis

To ensure the longevity and durability of the car chassis, surface treatments are applied:

Powder Coating: A popular surface finish for vehicle chassis parts, powder coating provides a durable, rust-resistant coating that enhances the chassis’s aesthetic appeal and protects it from corrosion.

Galvanizing: In this process, a thin layer of zinc is applied to the steel to protect it from rust and corrosion. This is particularly important for chassis parts exposed to road salt or water.

Anodizing: Anodizing is a process used primarily for aluminum chassis parts, which creates a protective oxide layer on the surface. This enhances the material’s resistance to corrosion and improves its overall durability.

Your Expert Partner for Automotive Car Parts: VMT

At VMT, we specialize in providing high-precision, customized automotive chassis parts, including frame rails, crossmembers, suspension mounts, and steering components. With over 15 years of experience, advanced CNC machining technology, and strict quality control, we ensure durable and reliable components for OEMs and aftermarket suppliers.

In addition to chassis components, we also offer a wide range of automotive parts, including Black Aluminum 45 60 90 120 Degree Racing Gas Oil Fuel Lines Connectors. Our selection of 4, 6, 10, and 12 AN Hose End Fittings ensures that we can meet the most demanding requirements of performance vehicles, racing applications, and other high-performance automotive needs.

In Conclusion

The automotive chassis is a vital component of vehicle design, providing the structural integrity and support for all other car systems. Whether made from steel, aluminum, or carbon fiber, the chassis plays a significant role in vehicle performance, safety, and efficiency. Understanding its design and function is crucial for automotive engineers, manufacturers, and car enthusiasts alike.

Frequently Asked Questions About Automotive Car Chassis

How to Remove Automotive Chassis Paint?

1. Use a chemical paint stripper designed for automotive use. Apply it evenly and let it sit as directed.

2. Scrap off loosened paint with a plastic or metal scraper.

3. Sandblast or use a wire brush for stubborn areas.

4. Clean the surface thoroughly before repainting.

What is the Difference Between a Car Frame and a Chassis?

Frame: The structural base of a vehicle that supports its weight and components.

Chassis: Includes the frame along with other parts like suspension, wheels, and drivetrain. The chassis represents the complete structural system.

What Happens if a Chassis is Damaged?

1. Compromise the vehicle’s structural integrity, making it unsafe to drive.

2. Cause alignment issues, leading to uneven tire wear or difficulty steering.

3. Reduce resale value significantly.

4. Severe damage may require professional repair or replacement to ensure safety and performance.