Snap fit joints represent a significant innovation in the assembly industry, delivering a fast, cost-effective, and dependable method for connecting components.

When conventional methods, such as screws or welding, are not suitable, snap-fit joints offer a straightforward yet robust solution for joining parts, thereby removing the necessity for additional tools or fasteners.

Understanding the mechanics of snap-fit joints, you can provide valuable insights for aiming to enhance product assembly and streamline manufacturing processes, unlocking a wide array of benefits.

What Are Snap Fit Joints?

Snap-fit joints are engineered to connect components by utilizing interlocking features that securely “snap” into position, establishing either a permanent or temporary connection without the need for extra hardware. These joints depend on the elasticity of the material to maintain the connection and are predominantly employed in plastic products, though they can also be adapted for other materials. Whether implemented in toys, automotive components, or electronic devices, snap-fit joints provide simplicity, strength, and versatility in their application.

Why You Should Consider Snap Fit Joints for Your Projects?

Snap-fit joints provide an innovative and hassle-free alternative to traditional assembly methods. Their ease of use leads to reduced labor costs and shorter production times, allowing you to increase overall efficiency. Furthermore, the flexibility of snap-fit joints means they are compatible with a variety of materials and applications. Snap-fit joints also reduce the need for specialized tools or fasteners, ultimately saving you money in both materials and labor.

Types of Snap Fit Joints

Snap fit joints come in various forms, each suited for different applications and requirements. Here are the most common types:

Cantilever Snap Joints

Cantilever snap joints are the most commonly utilized type of snap-fit joints. These joints feature a flexible beam that engages with a corresponding groove, providing strong retention while allowing for effortless assembly. Owing to their straightforward design and cost-effectiveness, cantilever snap joints are prevalent in a wide range of applications, including household products and automotive components.

U-Shape Snap Joints

U-shape snap joints operate on a principle similar to that of cantilever joints but incorporate a U-shaped groove that enhances security. These joints are particularly well-suited for applications requiring higher holding strength and are frequently employed in electrical enclosures as well as consumer goods.

Torsion Snap Joints

Torsion snap joints function through the application of rotational force, leveraging the material’s elasticity to establish a secure connection. These joints are ideal for designs that demand a precise and strong hold, making them particularly suitable for use in electronic devices and industrial machinery.

Annular Snap Joints

Annular snap joints are characterized by their circular design, offering a distinctive method of fastening. These joints are often utilized in round objects such as pipes, tubes, and circular cases, where space constraints and structural requirements play a significant role in the design process.

Injection Moulding vs 3D Printing Snap-fit Joints

Injection molding is ideal for mass production due to its efficiency and ability to handle large quantities, while 3D printing allows for complex and customized snap-fit designs that may not be possible with traditional manufacturing techniques.

| Feature |

Injection Moulding |

3D Printing |

| Material Options |

Wide variety of high-strength materials |

Limited to certain plastics and resins |

| Speed |

Faster mass production |

Slower, suitable for prototyping only |

| Cost |

Lower cost for high-volume production |

Higher per-unit cost, ideal for small batches |

| Precision |

High precision, especially in mass production |

Moderate precision, great for customization |

| Flexibility |

Limited by tooling constraints |

Highly flexible for complex designs |

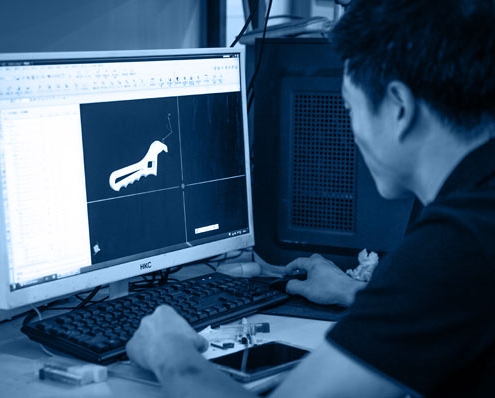

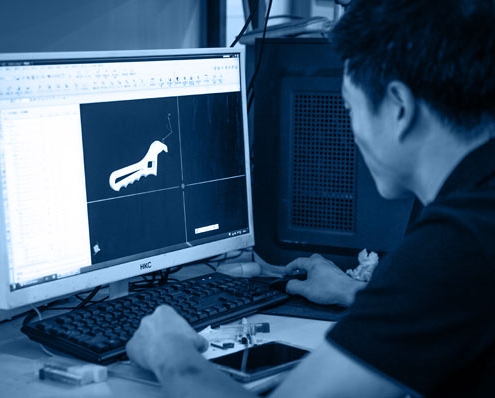

How to Design Snap Fit Joints?

Designing snap-fit joints requires a thorough understanding of material properties, forces, and joint geometry. By following these key steps, you can ensure that your snap-fit joints function effectively, are durable, and meet the specific needs of your application.

| Step |

Description |

| Step 1: Understand the Basic Types |

Identify the type of snap-fit joint based on your application: Cantilever (simple and flexible), U-shape (high retention strength), Torsion (rotational locking), or Annular (ideal for circular parts). Each type has specific advantages and suits different use cases. |

| Step 2: Choose the Right Material |

Select materials like ABS, polypropylene, or polycarbonate for flexibility and durability. Metals are ideal for high-stress environments, while elastomers are better for applications needing flexibility. Ensure the material’s elasticity and yield strength match the joint’s requirements. |

| Step 3: Determine the Joint Geometry |

Design key features such as snap arm thickness (balance strength and flexibility), snap angle (typically 3°–10°), and the undercut for secure locking. Proper geometry ensures ease of assembly and optimal performance. |

| Step 4: Calculate Design Parameters |

Perform calculations for snap arm deflection, maximum force capacity, and stress distribution. Use design tools or calculators to prevent localized stress and ensure the joint can handle operational forces without failure. |

| Step 5: Ensure Strength and Durability |

Verify the joint’s ability to withstand repeated stress and environmental conditions (temperature, moisture, chemicals). Design for fatigue resistance to ensure long-term functionality and reliability. |

| Step 6: Prototype and Test |

Create prototypes and perform real-world tests, such as insertion/removal, load, and durability testing. Identify and fix any flaws before finalizing the design. |

| Step 7: Finalize and Prepare for Manufacturing |

Adjust the design based on test results and prepare for manufacturing. Use injection molding for mass production or 3D printing for prototypes or small batches. Ensure tolerances and material constraints are considered in the final design. |

| Step 8: Assembly and Installation |

Assemble the joints, ensuring proper alignment to avoid damage. Test for functionality after assembly. Regular maintenance may be required for joints exposed to repeated stress or harsh conditions, extending their lifespan. |

Common Snap Fit Design Problems and Best Practices

Although snap-fit joints present various advantages, they also entail specific design challenges. Common concerns include part deformation, inadequate retention force, and material fatigue. To address these issues effectively, adhering to best practices in the design process is vital. Key practices involve selecting appropriate materials, optimizing joint geometry, and employing relevant snap-fit design calculators to anticipate behavior under stress. Furthermore, prototyping and testing the joints in realistic conditions are critical for mitigating common pitfalls associated with snap-fit design.

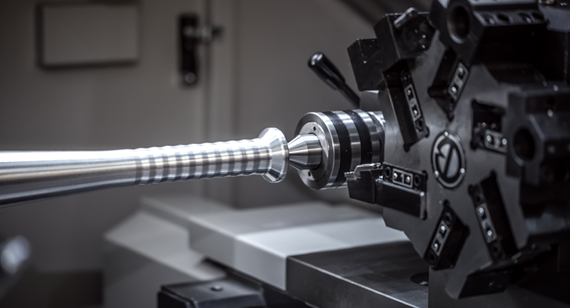

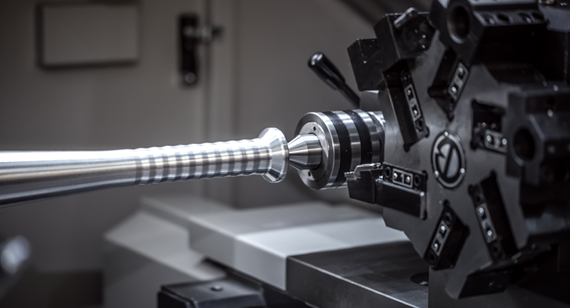

How to Manufacture Snap-fit Joints?

Manufacturing snap-fit joints typically involves injection molding for high-volume production or 3D printing for rapid prototyping. The choice of manufacturing method depends on the complexity of the design, the materials used, and the volume of parts required. Injection molding offers precision and cost-effectiveness for large-scale production, while 3D printing allows for greater design flexibility and faster iterations.

How to Install and Maintain Snap Fit Joints?

Installation of snap-fit joints is straightforward, as the parts simply snap together with the application of pressure. However, it’s essential to ensure that the parts are aligned correctly to avoid damaging the snap features. Regular maintenance involves inspecting the snap joints for signs of wear, such as cracks or deformation, and replacing the parts if necessary to maintain performance and safety.

Advantages and Disadvantages of Snap-Fit Connections

Advantages of Snap-Fit Connections

- Cost-Effective: Snap-fit joints are typically inexpensive to manufacture because they often require no additional fasteners or tools. The design simplifies assembly, reducing labor and material costs.

- Easy Assembly and Disassembly: Snap-fit joints are quick and easy to assemble, as no external fasteners or adhesives are needed. They can also be disassembled for maintenance or repair without special tools.

- Design Flexibility: Snap-fit joints can be designed in various forms, including cantilever, U-shape, torsion, and annular, allowing them to be tailored to a wide range of applications and materials.

- Automated Production: Snap-fit joints are easy to incorporate into automated manufacturing processes like injection molding, which speeds up production times and reduces costs.

Disadvantages of Snap-Fit Connections

- Material Limitations: Some materials may not have the required elasticity or durability to withstand the repeated stresses of snap-fit connections, leading to fatigue and failure over time.

- Design Complexity: While snap-fit joints are generally simple, designing them correctly can be challenging. The joint must be engineered to balance strength, flexibility, and ease of assembly, requiring precise calculations and testing.

- Limited Load Capacity: Snap-fit joints may not be suitable for applications that require high-strength connections or that experience high stresses, as they may not offer the same level of retention force as traditional fasteners like screws or bolts.

- Risk of Material Deformation: Snap-fit joints can cause material deformation if not designed correctly, especially if the material’s yield strength is exceeded or if repeated assembly and disassembly occur.

- Potential for Weak Joints: If the snap-fit design isn’t properly calibrated, there is a risk of weak joints that may break or wear out prematurely, especially under dynamic or harsh operating conditions.

Top Applications of Snap-fit Joints

Snap-fit joints are used in a wide range of industries, including automotive, electronics, consumer goods, and medical devices.

- Consumer Electronics: Snap-fit joints are widely used in consumer electronics like smartphones, laptops, and remote controls. These joints help assemble parts such as battery covers, screens, and enclosures without the need for screws or adhesives, ensuring ease of assembly and disassembly for repairs or upgrades.

- Automotive Industry: In automotive manufacturing, snap-fit joints are used for assembling interior parts like dashboards, trim panels, and door panels. They are also used in exterior components like lights and grilles, offering a quick and cost-effective assembly method while maintaining structural integrity.

- Medical Devices: Snap-fit joints are commonly found in medical device assembly, such as inhalers, blood glucose meters, and diagnostic equipment. These joints allow for quick assembly, ease of disassembly for cleaning or replacement of parts, and secure fittings in precision environments where high-quality, sterile conditions are necessary.

- Aerospace Components: In the aerospace industry, snap-fit joints are used in non-critical components like interior cabin parts, panel assemblies, and trim. They help reduce the weight of the overall assembly, contributing to the efficiency of the design, while also offering easy assembly and maintenance.

- Optical and Photographic Equipment: Snap-fit joints are used in the assembly of optical devices like cameras, binoculars, and microscopes. These joints provide precision and strength, ensuring that parts remain secure while allowing for easy assembly during the manufacturing process.

In Conclusion

Snap-fit joints are an innovative solution for efficient and secure assembly, offering multiple advantages across various industries. By understanding their types, design considerations, and applications, you can choose the right snap-fit joint for your project.