What is 8020 Aluminum?

As a special type of aluminum alloy material, 8020 aluminum is widely used in the field of CNC machining parts manufacturing. Its unique chemical composition and physical properties make 8020 aluminum excel in various industrial fields. The alloy is mainly composed of aluminum, silicon, iron, copper, manganese, magnesium, chromium and other elements, combined in precise proportions to provide excellent mechanical properties and corrosion resistance. This article will explore the characteristics, strength, advantages and disadvantages, and applications of 8020 aluminum.

What is 8020 Aluminum?

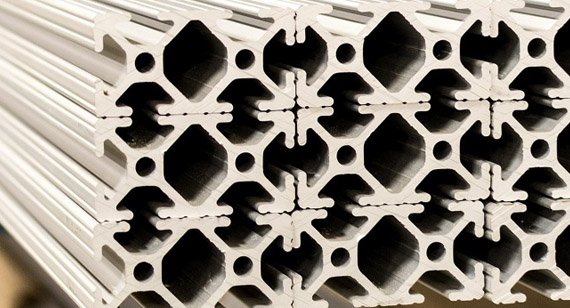

8020 aluminum, also known as 80/20 extruded aluminum or 80/20 frame aluminum, is a high-performance alloy composed of 80% aluminum and 20% other alloying elements (such as silicon, iron, copper, manganese, magnesium, chromium, etc.) in precise proportions. It exhibits excellent mechanical properties and corrosion resistance and is widely used in various industrial fields. It ensures strength and corrosion resistance while maintaining the lightness of the material.

Why is It Called 8020 Aluminum?

Aluminum alloy profiles usually appear in the market with “8020” or similar naming methods. The “80” and “20” here refer to the cross-sectional dimensions of the profile, such as 80mm in width and 20mm in height or thickness. However, they do not directly correspond to the percentage of alloying elements. Due to its specific size and performance, 80/20 aluminum alloy profiles are widely used in industrial automation, CNC machining, building frameworks and other fields.

What Material is 80/20?

Most often, it may refer to the Cr20Ni80 type of nickel-chromium alloy, an excellent resistance heating alloy used in many industrial fields.

It may also refer to aluminum alloy profiles with specific cross-sectional dimensions (such as 80mm in width, 20mm in height or thickness). This type of profile plays an important role in industrial automation, building frameworks, etc. due to its unique physical and chemical properties.

When referring to tungsten-copper composite materials, it is usually clearly marked as “tungsten-copper 80/20” to indicate that it is composed of 80% tungsten and 20% copper. This material combines the high hardness of tungsten and the excellent conductivity of copper.

Strength of 8020 Aluminum Extrusion.

The strength of 8020 aluminum extrusions depends mainly on the extrusion process, alloy composition, tempering treatment and profile geometry. The alloy microstructure can be optimized through solution heat treatment, quenching and aging processes, significantly improving the overall mechanical properties and strength. In addition, the wall thickness design, cross-sectional geometry and reinforcement characteristics of the profile have an important influence on the strength characteristics and load-bearing capacity.

Advantages and Disadvantages of 8020 Aluminum.

Advantage:

- Excellent mechanical properties:

When 8020 aluminum is a high-strength aluminum alloy with a specific alloy composition, it usually has excellent tensile strength and yield strength, which can meet the needs of various high-load applications.

- Good corrosion resistance:

8020 aluminum may contain specific alloying elements (such as nickel, chromium, etc.), the incorporation of which significantly enhances the aluminum’s tolerance to extreme environmental conditions. Whether in harsh working conditions of high temperature and pressure, or in acidic and alkaline environments or in chloride-rich solutions, 8020 aluminum can exhibit excellent corrosion resistance and oxidation resistance.

- Good machining performance:

8020 aluminum usually has good plasticity and machinability, and can be easily processed into parts of various shapes and sizes through extrusion, forging, cutting and other processes, which improves production efficiency and material utilization.

- Wide range of applications:

Due to its excellent performance, 8020 aluminum is widely used in aerospace, energy, chemical industry, medical equipment, marine engineering and other fields, providing important material support for the development of these industries.

- Lighter Weight:

Aluminum itself has a lower density, so 8020 aluminum is generally lighter than other metal materials, which helps reduce the overall weight of equipment or structures, improve energy efficiency and transportation convenience.

Disadvantages:

- Higher cost:

Compared with some ordinary metal materials, the cost of high-performance 8020 aluminum (such as high-strength aluminum alloys containing special alloying elements) may be higher, which may increase the manufacturing cost of the product.

- The heat treatment process has high requirements:

In order to give full play to the performance potential of 8020 aluminum, it usually needs to go through strict heat treatment processes (such as solution treatment, quenching and aging, etc.). These processes have high requirements for equipment and technology, and improper handling may affect the performance of the material.

What Other Types of Aluminum Materials Are There?

Aluminum materials are divided into many types due to their diverse properties and wide range of applications.

-

Classification of Alloy Components.

Pure aluminum: With a purity of over 99.0%, it is known for its excellent electrical conductivity, plasticity, corrosion resistance and good thermal conductivity. It is often used in wires and cables, heat sinks, decorative parts, chemical equipment and other occasions that do not require high strength.

Aluminum-copper alloy: The strengthening element is copper, which not only enhances the strength and hardness, but also maintains good processing performance. It is suitable for the manufacture of automobile radiators, ship accessories, etc.

Aluminum-manganese alloy: Manganese is the main alloying element, which gives the material excellent corrosion resistance and formability. It is widely used in construction, transportation and packaging fields.

Aluminum-magnesium alloy: The addition of magnesium improves corrosion resistance, welding performance and fatigue strength, but it cannot be strengthened by heat treatment. It is commonly used in ships, pressure vessels and other fields.

Aluminum-magnesium-silicon alloy: With magnesium and silicon as the main alloying elements, it is one of the most widely used alloys. It has medium strength, good corrosion resistance and welding properties, and is suitable for a variety of construction and industrial uses.

Aluminum-zinc-magnesium alloy: also known as super-hard aluminum, it has extremely high strength and hardness, but relatively weak plasticity and processability. It is the preferred material for high-strength demanding fields such as aviation and aerospace.

-

Other Common Types of Aluminum.

Industrial aluminum profiles: including angle aluminum, flat aluminum, hexagonal aluminum, round tube aluminum, square tube aluminum, etc., used to build various structures and mechanical parts.

Architectural aluminum profiles: covering door and window profiles, curtain wall profiles and aluminum alloy plates, which are widely used in exterior walls, roofs and interior decoration in the construction field.

Decorative aluminum profiles: such as aluminum alloy photo frames, decorative strips, etc., used for exhibitions, decorative painting mounting and building exterior beautification.

Electronic aluminum profiles: including radiator aluminum profiles and aluminum alloy extruded tubes, specially designed for heat dissipation and shell structure of electronic equipment.

8020 Aluminum Price.

The price of 8020 aluminum alloy is affected by many factors, including market supply and demand, raw material costs, production and processing costs, and regional differences. These factors interact with each other, making the price of this aluminum alloy show significant differences at different time points, geographical locations, and transaction scales.

Therefore, when you need to understand the specific price of 8020 aluminum alloy, you must comprehensively consider the current market environment, cost structure, and regional characteristics to obtain the most accurate and practical quotation.

8020 Aluminum Extrusion Application.

8020 aluminum extrusion is widely used, mainly in the following aspects:

Mechanical parts: 8020 aluminum extrusion profiles are often used to manufacture various mechanical parts, such as brackets, frames, connectors, etc., due to their good machinability and strength. These parts play an important role in automation equipment, robots, production lines and other fields.

Structural parts: 8020 aluminum extrusion is an ideal choice for applications that require lightweight and high strength. It can be used to construct various structural parts, such as workbenches, display racks, shelves, etc., which not only meets the load-bearing requirements but also reduces the overall weight.

Automation equipment: In automated production lines, 8020 aluminum extrusion profiles are often used to make conveyor belts, slide rails, guide rails and other components to ensure a smooth and efficient production process.

Automobile manufacturing: In automobile manufacturing, 8020 aluminum extrusion profiles can be used to make body structural parts, chassis parts, etc., which helps to reduce vehicle weight and improve fuel efficiency. At the same time, its good corrosion resistance and fatigue resistance also ensure the safety and durability of the car.

Furniture manufacturing: With the continuous development of modern furniture design concepts, 8020 aluminum extrusion profiles are increasingly used in furniture manufacturing. Its unique appearance and excellent performance make the furniture more beautiful, practical and durable.

Electronic products: In the field of electronic products, 8020 aluminum extrusion profiles can be used to make radiators, housings and other components to ensure the stable operation and heat dissipation of electronic products.

In Conclusion

8020 aluminum, with its unique T-slot design and extrusion machining technology, has become the preferred material in the industrial and electronic fields. As a high-performance aluminum alloy, it has shown broad application prospects in the manufacturing of CNC machined parts. Due to its excellent performance, easy machining and modular design, it can flexibly respond to various complex and customized needs. By accurately selecting machining technology and material specifications, 8020 aluminum can give full play to its advantages and provide efficient and innovative solutions for multiple industries.

High Quality 8020 Aluminum Processing Services.

If you are looking for a company that can provide high-quality 8020 aluminum extrusions and CNC machining services, VMT will be your trusted partner.

We are equipped with advanced extrusion equipment and CNC machines, combined with rich industry experience and technical strength to ensure that every product meets strict quality standards. Whether you need a customized aluminum solution or want to optimize your existing production process, we can provide one-stop services from design, and production to installation.

We pay attention to details and are committed to providing customers with efficient, accurate and cost-effective solutions. If you have any needs or questions, please feel free to contact us.

Frequently Asked Questions About 8020 Aluminum

Can You Cut 8020 Aluminum?

Yes, 8020 aluminum can be cut. When cutting 8020 aluminum, it is critical to ensure that the proper tools and techniques are used to achieve a clean, precise cut. Personal safety is also important during this process, so it is highly recommended to wear protective gear such as safety glasses and cut-resistant gloves.

What is The Yield Strength of 80/20 Aluminum?

The yield strength of 80/20 (commonly referred to as 8020) aluminum varies significantly based on factors such as its specific alloy composition, heat treatment status, and the manufacturer. Generally, when utilized as a structural aluminum alloy, 8020 exhibits a relatively high yield strength. However, for precise numerical values, it is essential to refer to relevant material data sheets or consult with suppliers for accurate information.

Will Extruded Aluminum Rust?

Extruded aluminum (including 8020 aluminum) will not rust. This is because aluminum, as a highly active metal, reacts quickly with oxygen in the air under natural environmental conditions to form a tight and hard aluminum oxide film. This naturally formed oxide layer acts like armor, effectively isolating the aluminum substrate from direct contact with the external environment, thereby preventing further oxidation and corrosion.