VMT’s blogs aim to share our practical experience and knowledge accumulated during the manufacturing and product development process. Our goal is to use these articles to help you improve product design and increase your understanding of CNC machining, 3D printing, rapid prototyping, low-volume manufacturing, and surface treatment technologies. The information we provide is designed to provide actionable guidance and insights for your CNC machining projects.

What is 4-axis and 5-axis CNC Machining?

If you’re facing challenges with complex designs or limited machine capabilities, the result can be inefficiency and low-quality output. To solve this, understanding 4-axis and 5-axis CNC machining will help you maximize precision and streamline your production process.

4-axis and 5-axis CNC machining are advanced techniques that enable multi-directional cutting, enhancing precision and reducing setup time. 4-axis machining incorporates an additional A-axis, while 5-axis machining includes two extra axes, which can be the A-axis, B-axis, or C-axis, depending on the specific configuration. These methods allow for the creation of complex designs with greater efficiency and accuracy. Specifically, 4-axis CNC machining allows rotation on the A-axis, whereas 5-axis CNC machining permits rotation on two of the three axes: A-axis, B-axis, and C-axis.

In the field of CNC precision machining, 4-axis and 5-axis CNC machining technologies have emerged as indispensable due to their remarkable machining capabilities and versatility. This article aims to demystify the definitions, distinctions, benefits, and drawbacks of 4-axis and 5-axis machining, while providing insights on which technology is best suited for various scenarios. Let’s delve deeper into the nuances between 4-axis and 5-axis machining, and discover how these advancements can elevate your manufacturing prowess.

Why Choose 4-axis and 5-axis CNC Machining?

The reason for choosing 4-axis and 5-axis CNC machining is that compared with traditional 3-axis machining, they can significantly improve machining capabilities, especially when machining complex curved surfaces and multi-angle machining, showing incomparable advantages. By increasing the number of rotating axes, these two technologies make the positioning of the tool in three-dimensional space more flexible and changeable, thus greatly improving machining accuracy and surface quality.

In addition, 4-axis machining and 5-axis CNC machining significantly reduce the number of clamping times and manual interventions required, which boosts processing efficiency and shortens the production cycle. These capabilities make them ideal for producing intricate and high-precision parts, improving productivity and overall quality.

What is 4-axis CNC Machining?

4-axis CNC machining, the full name of four-axis Computer Numerical Control (CNC) machining, is a high-precision and high-efficiency metal processing technology. It adds a rotating axis (usually the A-axis or B-axis) to the traditional three-axis CNC machining (i.e., the three linear axes of X, Y, and Z), thereby achieving processing capabilities in four dimensions. In the 4-axis CNC machining process, the workpiece is fixed on the workbench of the machine tool, and the tool moves through the three linear axes of X, Y, Z and the rotation axis to achieve precise processing of the workpiece. The existence of the rotation axis allows the tool to rotate around an axis of the workpiece, thereby realizing the processing of complex curved surfaces.

What are the Advantages and Disadvantages of 4-Axis CNC Machining?

Advantage:

- Improve processing accuracy: Improve processing accuracy by accurately controlling the position and angle of the tool in three-dimensional space.

- Improve production efficiency: reduce the number of clamping times and manual interventions, and shorten the production cycle.

- Enhanced processing capabilities: Able to process parts with complex curved surfaces and angles.

- Reduce labor intensity: The highly automated processing process reduces the labor intensity of operators.

Disadvantages:

- Constrained by Geometry: Although 4-axis CNC machining offers a high degree of flexibility, it can still face challenges with some extremely complex geometries.

What is 5-axis CNC Machining?

5-axis CNC machining is an advanced CNC machining technology that adds two rotational axes, usually the A-axis and the C-axis ( It may also be any two of the A, B, and C axes), thereby achieving processing capabilities in five dimensions. 5-axis CNC machining achieves precise positioning and rotation of the tool in three-dimensional space by simultaneously controlling the movement of five axes, making the processing process more flexible and changeable.

5-Axis CNC Machining Advantages and Disadvantages

Advantage:

- Improved machining accuracy: 5-axis CNC machining can process multiple surfaces in one clamping, reducing errors caused by multiple clampings, thus improving machining accuracy.

- Improve production efficiency: It can complete the processing of multiple surfaces at one time, reduce the number of tool changes and clamping times, significantly shorten the processing cycle, and improve production efficiency.

- Enhanced processing capabilities: Able to process parts with complex curved surfaces and high-precision requirements.

Disadvantages:

- Complex programming and operation: Professional programming and operating personnel are required to ensure the smooth progress of the machining process. Multiple factors such as tool paths and cutting parameters need to be considered during programming to ensure machining quality and efficiency.

- High requirements on operators: Operators need to have rich experience and skills to cope with various situations that may arise during the processing.

What is 3+2-axis CNC Machining?

After having an in-depth understanding of 4-axis and 5-axis CNC machining technology, you may be curious to ask about another machining method that is often mentioned in the CNC industry-3+2-axis CNC machining.

3+2-axis CNC machining is a special CNC (computer numerical control) machining method, also known as positioning 5-axis machining. It combines the capabilities of traditional three-axis CNC machining (X, Y, Z axes) with two additional rotary axes (usually A and B or C), but these two rotary axes are mainly used before machining. Position the cutting tool at a specific tilt position and maintain this position throughout the machining process, rather than continuously manipulating the tool during machining. Therefore, despite using five axes, the actual machining operation is still similar to three-axis machining, but at different tilt angles.

Features of 3+2-axis CNC machining

- Positioning processing: The fourth and fifth axes (rotary axis) are mainly used to position the tool at the best angle before processing to optimize cutting conditions. Once positioned, the axes remain stationary while the X, Y, and Z axes perform standard cutting movements.

- Enhanced machining capabilities: 3+2-axis machining allows the use of shorter, more rigid cutting tools that are able to machine closer to the workpiece surface, thereby improving machining accuracy and surface quality. At the same time, due to the flexibility of the tool tilt angle, it can also process complex features that are difficult to achieve with traditional three-axis machining, such as steep walls, cavity undercuts, etc.

- Improved productivity: 3+2-axis machining can reduce processing time and material waste by reducing tool path overlap and shortening tool travel distance. In addition, it reduces uncertainty and errors in the production process due to reduced clamping times and workpiece movements.

Key Differences Between 4-Axis and 5-Axis CNC Machining

Number and function of axes:

- 4-axis CNC machining: A rotation axis (usually the A-axis) is added to the standard X, Y, and Z axes. This axis usually rotates around the X-axis or Y-axis, allowing the workpiece to rotate 360°. This design allows the tool to process the workpiece from different angles, and is especially suitable for processing parts with complex curved and inclined surfaces, such as spirals and inclined surfaces.

- 5-axis CNC machining: Adding another rotation axis (usually the B-axis or C-axis) to the 4-axis to form two rotation axes. This allows the tool to cut in more directions and angles, allowing access to the workpiece from almost any angle. This processing method is very suitable for processing complex three-dimensional shapes, such as turbine blades, molds, etc., and can greatly improve processing accuracy and efficiency.

Processing capabilities and flexibility:

- 4-axis CNC machining: Although a rotation axis is added, its processing capabilities and flexibility are still limited compared to 5-axis machining. In the processing of some complex shapes or special angles, it may be necessary to clamp or adjust the position of the workpiece multiple times, which increases the difficulty and cost of processing.

- 5-axis CNC machining: With two axes of rotation, the tool can cut in multiple directions and angles, reducing clamping times and workpiece adjustment time. This not only improves processing efficiency, but also reduces errors and damage that may be caused by multiple clampings. At the same time, 5-axis machining can complete the processing of multiple surfaces at one time, greatly improving processing accuracy and flexibility.

Cost:

Generally speaking, 5-axis CNC machining costs more than 4-axis CNC machining due to its greater complexity, functionality, and accuracy.

Applications for 4- and 5-axis CNC machining

4-axis CNC machine tools continue to demonstrate their core values in multiple fields:

- Aerospace: Because of its excellent performance in processing high-precision parts such as turbine blades and complex fuselage components, it is favored by the aerospace industry.

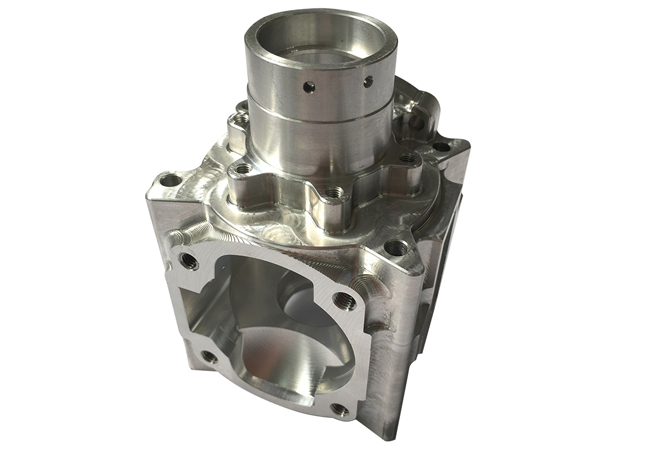

- Automobile: It is widely used in the efficient production of key components such as engine blocks and crankshafts as well as precision body parts to improve production efficiency and product quality.

- Electronic products: used to manufacture precision electronic components, including circuit boards, casings, etc., to meet the high requirements for precision and accuracy of electronic products.

5-axis CNC machine tools are widely used in multiple industries:

- Aerospace: Precision manufacturing of complex precision components for aircraft engines and airframes.

- Automotive: Efficient production of prototypes, engine components and complex custom parts.

- Medical: Precise processing of orthopedic implants such as hip and knee replacements to meet complex shape requirements.

How to choose a 4-axis or 5-axis CNC machining method depending on the situation?

- Processing requirements and complexity:

Evaluate the complexity and machining requirements of the part to be machined. If the part has complex curved surfaces, and requires highly precise multi-faceted machining, or if machining efficiency is the primary consideration, then 5-axis CNC machining may be more suitable with its comprehensive machining capabilities and efficiency. On the contrary, if the part shape is relatively simple, or the main processing needs are concentrated on a few planes, 4-axis CNC machining may be sufficient to meet the needs. - Your budget:

Generally speaking, the cost of 5-axis CNC machining is usually higher than that of 4-axis CNC machining due to its increased complexity, functionality, and accuracy. For projects with a limited budget, 4-axis CNC machining is a more economical option that provides sufficient detail. - In terms of production efficiency:

5-axis CNC machining can reduce the number of clamping times and machining cycles, thereby improving production efficiency. 4-axis CNC machining may require multiple clamping and adjustments in some cases, and the production efficiency is relatively low. If your target delivery time is very short, then you can choose 5-axis CNC machining.

In Conclusion

4-axis and 5-axis CNC machining technology occupies an important position in modern manufacturing. 4-axis machining improves efficiency and accuracy by adding a rotating axis, and is suitable for processing multi-angle parts, and the cost is relatively controllable. 5-axis machining achieves more comprehensive and high-precision processing capabilities, and is especially good at processing complex three-dimensional shapes. Although the initial cost is higher, it significantly improves production efficiency and processing quality.

VMT is an expert in the field of CNC machining. We focus on providing customers with customized high-quality machining services. We have advanced CNC processing equipment and rich manufacturing experience, and can accurately process parts according to customer’s specific requirements and drawings. Whether dealing with complex geometries, meeting tight tolerances, or machining specialty materials, we provide reliable solutions to ensure our customers’ precision component needs are met.

Frequently Asked Questions About CNC Machining

What is 3-axis CNC?

3-axis CNC (Computer Numerical Control) refers to a CNC machine tool with three main axes of motion. These three axes are usually the X-axis, Y-axis and Z-axis, which respectively control the horizontal (X-axis), longitudinal (Y-axis) and vertical (Z-axis) movement of the tool on the workbench. This kind of machine tool is controlled by a computer connected to the machine tool. Using the processing parameters obtained from the CAD (computer-aided design) model, the instruction code is sent to the machine tool to perform turning, drilling, milling, engraving and other processing operations to remove the workpiece. part of the material.

What is 6-axis CNC?

The 6-axis CNC adds at least two additional rotation axes to the traditional three-axis (X, Y, Z axis) machining. These additional rotational axes, often called the A-, B-, or C-axes (depending on the design and configuration of the machine tool), allow the machine tool to perform more complex rotational movements during machining.

What is a 4-Axis CNC Machine?

A 4-axis CNC machine is an advanced type of CNC (Computer Numerical Control) machine that allows for precise machining of a workpiece with an additional rotational axis. In traditional 3-axis CNC machining, the machine moves the tool along the X, Y, and Z axes (forward/backward, left/right, up/down).

However, 4-axis machining adds a rotary movement around the X-axis, known as the A-axis. This feature enables the machine to rotate the workpiece, allowing for more complex geometries and making it ideal for machining parts that require operations on multiple sides or intricate cuts, such as creating arcs or working on cylindrical surfaces.

What are the Primary Differences Between 5-axis and 6-axis CNC Machining Technologies?

The primary difference between 5-axis and 6-axis CNC machining lies in the number of movement axes involved in the process. A 5-axis CNC machine operates with five axes of motion (X, Y, Z, and two rotational axes, usually A and B), allowing it to create complex parts with high precision and intricate geometries by positioning the tool in multiple directions.

A 6-axis CNC machine adds a sixth axis (usually a rotational axis, often C), which provides even more flexibility and precision for machining complex shapes, especially for parts with undercuts or intricate angles. The extra axis in 6-axis machining improves efficiency, reduces setup times, and enables the creation of more complex components without repositioning the part.