We’re not only the fastest manufacturing supplier of machined prototypes but also the most reliable source of on-demand production parts. Why is this important? You have a single-source supplier from concept validation to short-run production.

We offer more competitive pricing at higher quantities in addition to tighter tolerances, hardware assembly, first article inspection (FAI) reporting, material certifications, and additional finishing options like anodizing and chromate plating. It’s CNC machining designed around your project needs—whether prototyping or production.

4 reasons to choose machined production parts

1. Reduced Piece-Part Price with Higher Quantities

Lower your part cost when you order higher volumes of production parts.

2. Inspection Reporting and Certifications

Get added quality assurance from conventional FAI reporting, CoC documentation, and AS9100 certification.

3. More Finishing Options

Choose from anodizing and chromate plating for complete parts from one supplier.

4. Supply Chain Flexibility

Avoid warehousing fees by ordering only the amount (starting at quantity 15) you need each month.

Production Capabilities for CNC Machining

Tolerances

- Shop tolerance = +/- 0.005

- Able to hold +/- 0.002 for reamed holes (print required)

- Up to +/- 0.002 feature location on the same side (print required)

Surface Roughness

- Flat and perpendicular surfaces = 63 µ in

- Curved surfaces = 125 µ in

Surface Finish Options

Multiple surface finishes are available for production machined parts.

Chromate Plating

Your chromate plating options at Protolabs:

- Type I, Non-ROHS (Yellow)

- Type II, ROHS (Clear)

- Class 1A: for maximum protection against corrosion, painted or unpainted

- Class 3: For maximum protection against corrosion where low electrical resistance is required

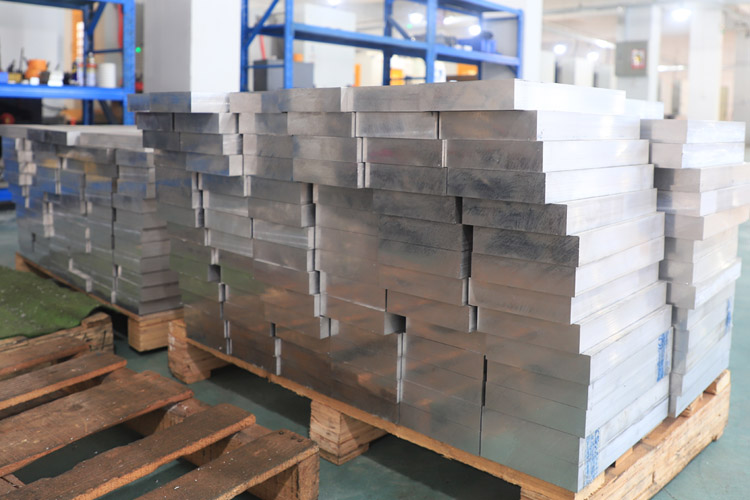

Production Materials for CNC Machining

| MATERIALS | MAX. PART SIZE |

|---|---|

| Aluminum 6061 | 7 in. x 15 in. x 3 in. / 15 in. x 18 in. x 1.75 in. |

| Aluminum 7075 | 7英寸x 15英寸x 3英寸/ 15英寸x 18英寸x 1.75英寸 |

| ABS | 7 in. x 15 in. x 1.75 in. |

| Steel 1018 | 7 in. x 15 in. x 1.75 in. |

| Steel 4140 | 7 in. x 15 in. x 1.75 in. |

| Plastic: Acetal (black, white) | 7 in. x 15 in. x 1.75 in. |

| Plastic: Acetal Copolymer (black, natural) | 7 in. x 15 in. x 1.75 in. |

| Plastic: PEEK (black, natural) | 7 in. x 15 in. x 1.75 in. |

| Plastic: PEI (Ultem) | 7 in. x 15 in. x 1.75 in. |

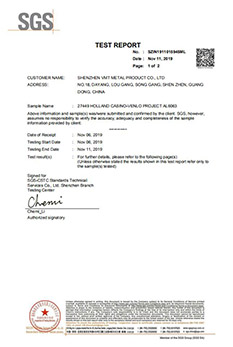

Quality report

When all your parts are processed in VMT, you can rest assured that VMT is a customized processing factory with ISO9001:2015, SGS and IATF16949 certification. In order to provide high quality and competitive prices, VMT combines the differences for different designs Processing technology, in order to make zero defects, we have an automatic inspection machine to check the size and appearance, whether it meets customer standards, but for processed parts, we also provide regular inspection reports, such as material certification SGS report, FAI, certificate of conformity (CofC ) Documentation and other certifications, such as ISO 9001 and AS9100.

Certifications